The Exhaust Manifold

One of the most critical components of the internal combustion engine is the exhaust manifold. The purpose of the exhaust manifold is to gather the exhaust gases from the cylinders into one exhaust channel. This pipe then directs the gases to the other parts of the exhaust system for processing and release to the atmosphere.

The exhaust manifold is relatively simple, as it is characterized by sturdy curved pipes that merge into one pipe. However, it is a serious engineering component that merges and channels exhaust gases and optimizes backpressure, among other crucial functions related to the exhaust system.

Like other auto parts, exhaust manifold parts develop issues that may prompt repairs and replacements. For optimal vehicle performance, you should deal with exhaust manifolds that can stand the test time. Only the best CNC machining services using the most suitable materials can guarantee that.

Cast iron, aluminum, and steel are some of the materials we can use to manufacture the best exhaust manifolds.

In this article, we review this technology and insist on expertly done solutions. Read on to learn about the function, parts, and CNC machining options for the exhaust manifold.

What Is A Car Exhaust Manifold?

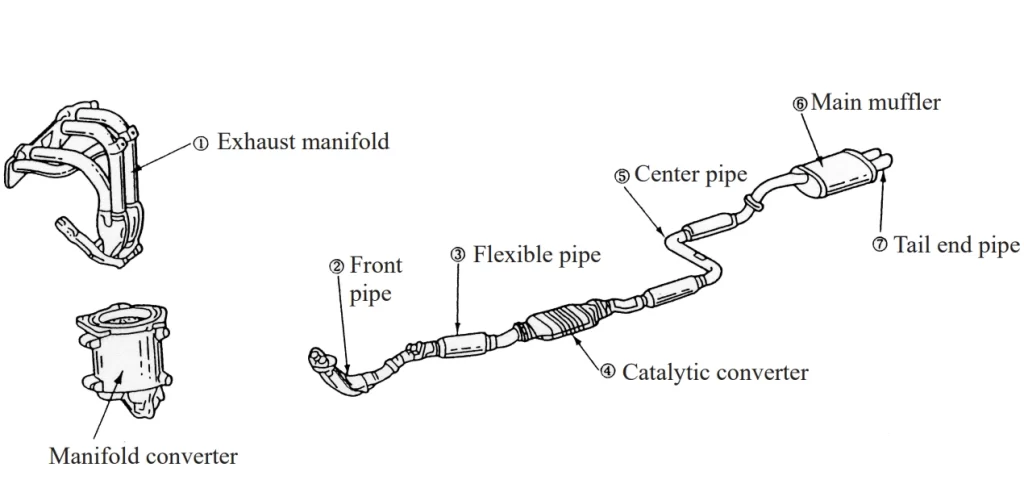

The car exhaust manifold is the first part of the exhaust system. It is located next to the cylinders for waste gas collection from each of the exhaust ports. It directs the collected exhaust to a single output channel.

The exhaust manifold and other exhaust system parts

That is before the exhaust gases reach the catalytic converter. The series of tubes channel the exhaust gases for expulsion. As we will discuss below, this is not the only function of this manifold.

How The Exhaust Manifold Compares To The Intake Manifold

It is important not to mistake the car exhaust manifold with the intake manifold. The intake manifold is different because it delivers the air-fuel mixture to the engine.

A car intake manifold

The exhaust manifold handles the combustion by-products. However, the two types of manifolds are similar in that they enhance engine efficiency and car performance.

A car exhaust manifold

What Are The Functions Of The Car Exhaust Manifold?

As you source the best engine manifolds, considering the purpose of the exhaust manifold is critical. Armed with the basics, you can better expound product benefits to users or recommend the best types.

With ProleanTech as your manufacturer for these components, you never have to worry about product relevance and quality. Manifolds serve the following fundamental functions.

Gathering The Exhaust Gas

Since the exhaust manifold connects to the engine cylinder, the exhaust gas from the combustion process enters this component first. This is the component’s primary function.

This happens when the exhaust valves open and release the gases, which are under high pressure and temperature at the manifold.

Channeling The Exhaust Gases

After collecting the gases, the exhaust manifold passes them through a series of runners. The goal of this channelling is to combine the gas streams into one. Gas transportation in a single stream is more efficient.

Expelling the Exhaust Gases

This is another critical function entailing directing the gases to the subsequent exhaust system parts. In most cases, the catalytic converter is the next recipient of these gases. Other downstream parts include the tailpipe and muffler.

Optimizing the Back Pressure of the Cylinder

The pressure emanating from the cylinder action must be equalized or minimized, a function that the exhaust manifold also undertakes. The component is designed to reduce back pressure by balancing the gas flow. This also helps enhance the engine’s performance.

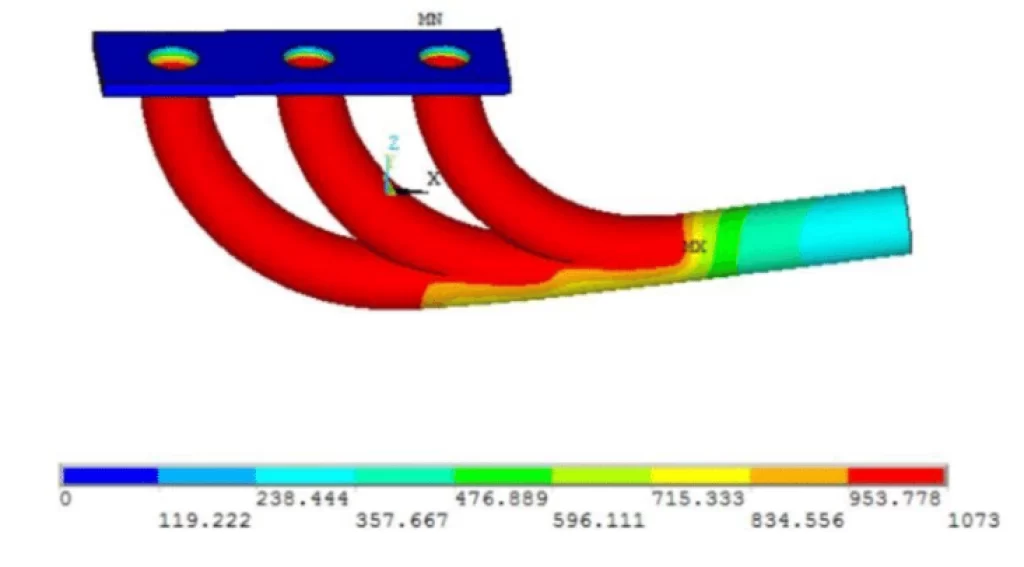

Managing The extreme temperature of the exhaust gases

As mentioned, the exhaust gases are extremely hot. The image below shows the temperature distribution around the exhaust manifold.

Temperature distribution along the exhaust manifold

That’s why the manifold is also built to manage these temperatures. The common materials for the exhaust manifold are heat-resistant to ensure that the component manages the heat.

It is also important to prevent heat from spreading to other parts of the engine. You will find a shield around the manifold for this purpose.

Try Prolean Now!

Materials To Use For The Exhaust Manifold

The material for the exhaust manifold can differ depending on the driving conditions and a vehicle’s specific requirements. Therefore, it is important to identify the different possible materials for this component.

This information makes it easier to recommend the most suitable material to ensure the best heat resistance, longevity, and overall performance of the manifold and car.

In case you need more guidance regarding materials, ProleanTech experts are available. We have CNC machined 100+ materials, and the list keeps on growing.

Aluminum For Low Weight And Affordability

Aluminum is one of the preferred materials for this important car component. One of the reasons is the low weight, which means the weight added to the exhaust system is minimal.

An aluminum exhaust manifold

The material’s corrosion and heat resistance are valuable. The metal has a high melting point so the heat from the engine will not affect its functionality.

Being a cost-effective metal, aluminum is great for users on a budget. It is an effective money-saving option for anyone looking for an affordable yet reliable exhaust manifold.

This Guide to Aluminum CNC Turning expounds on the benefits of aluminum for parts.

Carbon Steel For Thermal Properties

Good thermal properties make carbon steel a candidate for exhaust manifold production. The material is also cost-effective and durable.

A mild steel exhaust manifold

Cast Iron For Durability And Affordability

Cast iron is a regular feature in automotive parts, including the exhaust manifold. Auto users and manufacturers prefer materials that are durable, easy to use, and affordable. Cast iron provides all these factors.

Cast iron exhaust manifold

Notably, the metal has the disadvantage of radiating too much heat under the hood. Insulating the exhaust manifold often adequately addresses the high temperatures.

The material is also relatively heavy, which can contribute to excess weight in the car. The material’s high cost-effectiveness tends to balance all these negatives. That’s why many car users are still ready to live with the material’s inconveniences.

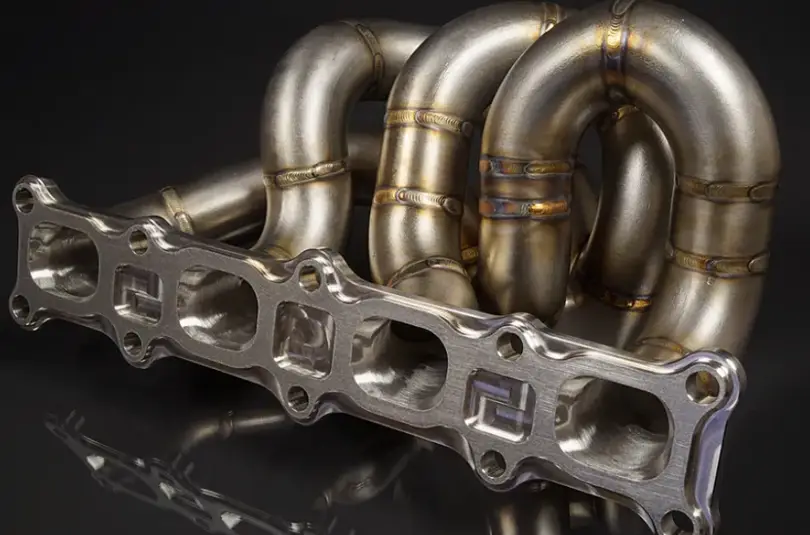

Stainless Steel – Corrosion And Heat Resistance

A stainless steel exhaust manifold

Stainless steel for the exhaust manifold is excellent. The material’s suitability goes beyond resisting rust, which is also crucial for the component.

The material has many suitable characteristics, starting with high temperature resistance. The heat at the engine exhaust poses no problem to the functionality of this metal.

If the component is made of chromium-nickel stainless steel grades, corrosion resistance and weldability are unmatched. The stainless steel is also excellent in ductility and fatigue strength.

Try Prolean Now!

Your Manufacturing Process Options For Custom Exhaust Manifolds

Manufacturing custom exhaust manifolds entails different manufacturing processes including CNC Machining. Note these options to ensure you always choose the right exhaust manifold parts and make more effective recommendations to users or buyers.

When you need a company to handle the manufacturing process, talk to ProleanTech, get a quote, and wait for fast, reliable, and cost-effective solutions.

Casting Method for Exhaust Manifold

High pressure or gravity die casting may produce exhaust manifolds depending on the application and volume. A mould in the shape of the manifold is prepared.

The metal is melted in an oven and poured into the mould cavity. The solidified part is then subjected to final processes such as grinding.

Exhaust manifolds in a foundry

Get more insights about the process in this guide: Die Casting Process Explained.

CNC Machining For The Highest Precision

Our automotive die casting services give the exhaust manifold its fundamental shape, but it may not provide the required tolerances. The precision of CNC machining is instrumental in giving the product its final shape.

Custom manifolds require specific tolerances and dimensions, which are achievable through our quality CNC drilling, milling, and shaping services.

Exhaust manifold with a CNC-machined surface

Surface Treating The Exhaust Manifold

Like other car parts, the exhaust manifold requires surface treatment to prevent rusting, scratches, and other surface damage. Surface coating is popular for this part because the process prevents corrosion and enhances thermal protection.

A rusty exhaust manifold

Ceramic chrome coating offers excellent thermal protection and corrosion resistance. The coating approach depends on several factors, including the material. For instance, the porous nature of cast iron means a base coat is required before a final one.

Passivation and anodizing are great surface treatment technologies if you require an enhanced appearance and corrosion resistance. Passivation particularly enhances the part’s corrosion resistance and appearance.

Conclusion

We have provided an overview of the exhaust manifold, covering the exhaust manifold purpose and materials used, among other things. The lessons here are crucial because they lay a foundation for better part selection and recommendation.

Do you have any further questions about the exhaust manifold? Do you want to order the most reliably manufactured exhaust manifolds? You’ve all this covered by the team at ProleanTech.

Contact us now, and we will escalate it for your best CNC machining experience!

FAQs

What Happens When An Exhaust Manifold Fails?

When the exhaust manifold fails, the most obvious result is exhaust gas leakage. This leakage causes noise and poor engine performance.

What Happens If You Drive With A Bad Exhaust Manifold?

If you drive a car with a bad exhaust manifold, you can encounter several problems, some to you as the driver and others to the system and the environment. For instance, a manifold leak can release toxic exhaust gases into the car and cause sickness.

Using a bad exhaust manifold subjects the engine to higher fuel consumption despite the reduced performance.

What Is The Main Function Of The Manifold?

The manifold’s main function is to gather the exhaust fumes generated in the internal combustion engine and send them to other parts of the exhaust system such as the catalytic converter and muffler.

What happens if you don’t replace your exhaust manifold?

Not replacing the exhaust manifold when necessary can cause poor engine performance, higher fuel consumption, and the release of harmful exhaust substances into the atmosphere. Even worse, engine components could get damaged.

How Much Does It Cost To Replace The Intake Manifold?

The cost to place the intake manifold of a car can vary with the design of the manifold, car make, and labour cost.

What Causes An Exhaust Manifold To Go Bad?

The exhaust manifold can go bad because of the car’s operating conditions, environmental conditions, or even a manufacturing defect.

For instance, if the car is continuously driven over rough terrains, the bolts holding the manifold could fall out.

The heat around the engine can also cause the component to go bad, especially if it is not built from heat-resistant material.

What does a bad manifold sound like?

A lousy exhaust manifold produces a ticking or tapping sound, particularly during accelerations and cold starts.

What is the life expectancy of an exhaust manifold?

A good design using the best materials can help the exhaust manifold last for the car’s full-service life. However, this is not always the case because the driving conditions, materials used, and maintenance levels are not optimal.

Can the exhaust manifold be repaired?

Yes, the exhaust manifold can be repaired to enhance its usability. For instance, cracks can be welded.

How does an exhaust manifold work?

The exhaust manifold collects combustion gases from the engine’s cylinders and channels them to other exhaust system parts downstream.

Do custom car manifolds really affect car performance?

Yes, custom car manifolds can affect car performance. The design and length of the collectors affect the car’s revolutions per minute (RPMs). A custom manifold can be designed to enhance exhaust flow, fuel efficiency, and engine performance.

0 Comments