Flywheel in car

The flywheel on an engine is synonymous with manual transmission cars and is common in auto CNC machining projects. It is a basic part of this type of car, yet many people fail to notice it alongside its important functions.

Connected to the crankshaft of the engine, this component stores rotation power releases it when required, and plays several other crucial roles. Although this component adds weight to the engine, it is instrumental in maintaining smooth torque and enhancing the car’s overall functionality.

The flywheel in the car must be built from suitable materials that match the requirements for rigidity, heat resistance, and durability. Popular materials for this auto part include cast iron, aluminum, and steel.

Manufacturing the part is also a critical area to focus on. You should insist on the best CNC machining services, casting, forging, and related processes.

ProleanTech-Your custom parts manufacturing partner– has proven to be the go-to company for the best CNC machining solutions for flywheels locally and overseas. You can bank on us for all types of flywheels and fast, cost-effective results.

Read on to discover the flywheel function, construction, and more about the component.

What Is A Flywheel In A Car?

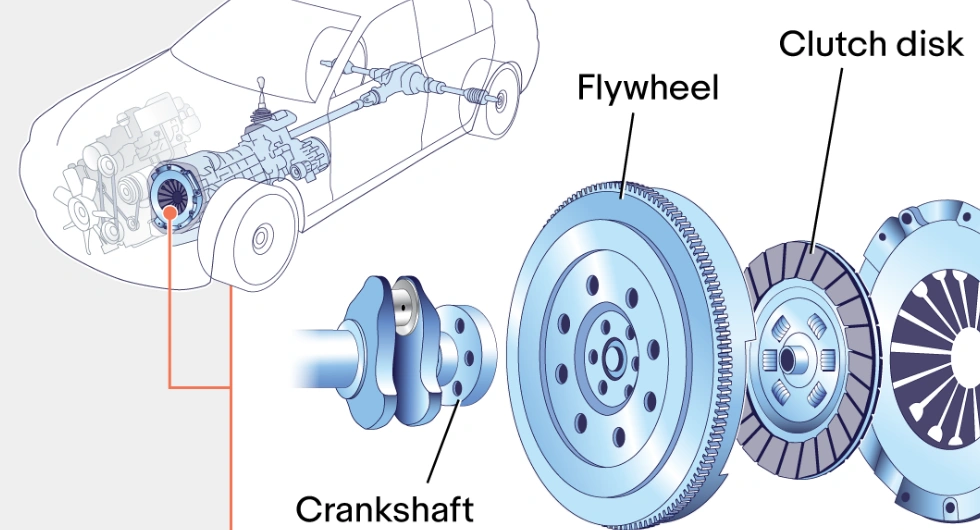

A flywheel in a car is a heavy disc-shaped component that is fixed to the output shaft of a manual transmission car. It is integral to the clutch mechanism, allowing for the smooth operation of the transmission system, as shown in the flywheel and clutch diagram below.

A flywheel and clutch diagram

Fundamentally, the manual transmission flywheel stores and releases rotational kinetic energy as required. This mechanical device eliminates speed variations to enhance performance stability.

It is one of the many car parts ProleanTech’s CNC machining segment manufactures.

Try Prolean Now!

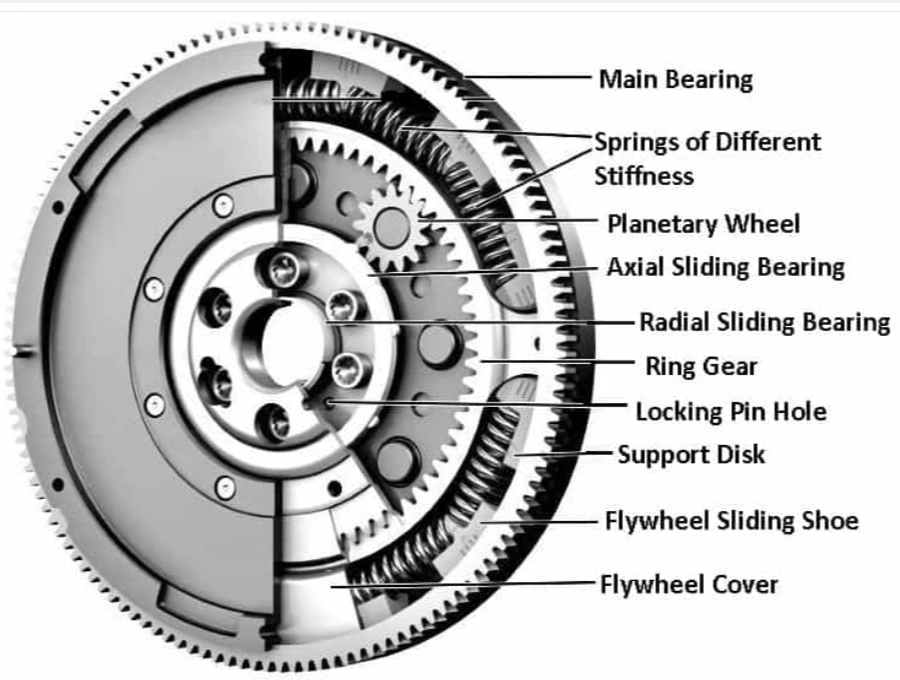

Parts Of The Flywheel: The Secret To High-Performance Flywheel

To understand how the flywheel works and know the nature of manufacturing to insist on, let’s look at its main parts, which include the rim and bore. Modern flywheels have additional features such as covers, springs, bearings, and a sliding shoe.

The parts of a flywheel

Rim Of The Flywheel – Energy Storage

This is the outer disc of the manual transmission flywheel. It is usually heavier than the more central parts to enhance kinetic energy storage. Its outer surface has teeth that engage with the starter motor during startup. When the engine is running, the flywheel generates rotational inertia.

The outer rim is one of the parts that showcases the immense CNC Machining & Its Advantages. The precision of CNC machining is instrumental in ensuring balanced weight distribution.

CNC machining a flywheel

The Bore Of The Flywheel – Links to Output Shaft

The bore is the hollow space at the center of the flywheel. This is the connection point to the engine output shaft. It must be designed and manufactured to meet the parameters (diameter) of the engine output shaft.

The Flywheel Cover For Protection

This is a robust protective cover for the flywheel and related components.

The Spring Dampens Vibrations

The modern manual transmission flywheel also contains a spring, whose main function is to dampen unwanted vibrations. It enhances the transmission’s smoothness and stability. In other words, it is a protective feature against sudden shocks.

Dual-mass flywheel springs

Bearings – Axial And Radial

Radial forces are generated as the flywheel on an engine operates. These bearings are crucial in arresting these forces and the resulting imbalances for an overall stable operation.

The Sliding Shoe Of The Flywheel

The sliding shoe is a protective lining on the inner surface of this component. It minimizes wear and tear that is common during the flywheel’s operation. This part is valuable because it enhances the flywheel’s durability.

Try Prolean Now!

What Is The Function Of A Flywheel? Energy Storage And More.

The flywheel has multiple functions, from torque transfer to energy storage and vibration reduction to speed synchronization.

Understanding the different functions of the flywheel in the car is crucial because this knowledge helps in flywheel selection based on factors such as car size and model.

ProleanTech incorporates all the functions of the flywheel in flywheel designs and manufacturing processes. We adhere to specific requirements, such as tolerances and surface finishes.

Our tolerances of ±0.0002″ (0.005mm) are the best. They ensure the highest weight balance and vibration control.

The main functions of this essential car transmission part are;

The Storage of Rotational Kinetic Energy

This is the fundamental flywheel function. The device stores kinetic energy from the crankshaft. This energy maintains smooth engine speed despite variances in the load.

The Efficient Transfer Of Torque

The flywheel stores kinetic energy and helps the transmission system to deliver torque smoothly from the engine. It promotes engine performance and health by ensuring measured and continuous torque transfer.

To Enhance Clutch Performance

The clutch and flywheel in the car work closely. The flywheel has a surface for engaging with the clutch for manual transmission. It plays an instrumental role in the smooth connection of the engine and transmission system. It enhances the gear changes and overall car operation.

Dampening Car Vibrations

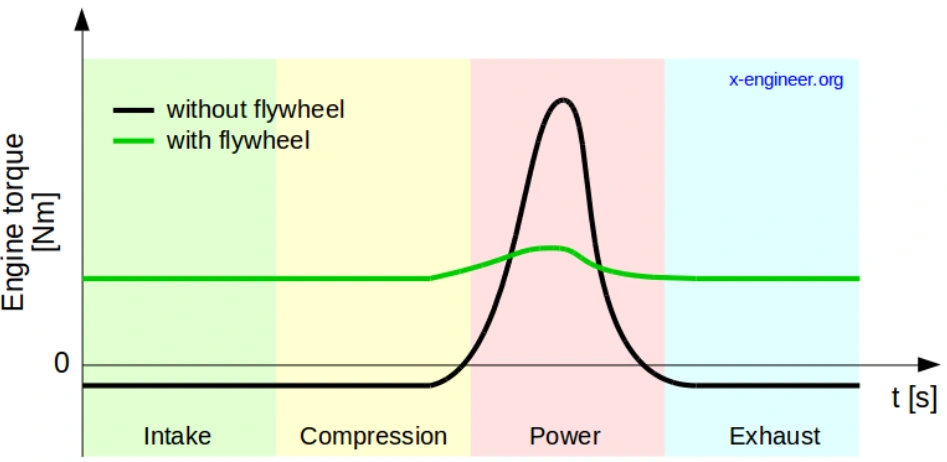

Another flywheel function is to reduce vibrations caused by engine operation. As the car engine undergoes the combustion cycle, the resulting power generation is normally non-uniform.

Vibration dampening by a flywheel.

Vibrations evidence this irregularity. A quality flywheel on an engine smoothens these vibrations for optimal car comfort and safety.

Helping Maintain Crankshaft Operation

The manual transmission flywheel also helps maintain the rotation of the crankshaft, a critical component of the combustion process. After each power stroke, the flywheel stores some energy, which it can release as and when needed by the crankshaft.

The Different Types of Flywheels in Cars To Consider

When dealing with flywheels for cars, you should match cars with the right flywheel types. This minimizes maintenance problems, ensures optimal car performance, and, ultimately, helps users save money.

Car flywheels come in different designs and sizes, giving rise to the following major types.

Single Mass Flywheel (SMF) – Simplicity and Performance

As its name suggests, a single mass flywheel is one solid metal piece. It is simple in design and lasts long, but it transmits more vibration. It is mostly common in sports cars and conventional vehicles. A major drawback of the SMF is that it transmits significant vibrations to the drivetrain.

A single-mass flywheel

Dual Mass Flywheel (DMF) For Added Comfort/Safety

The dual mass flywheel (DMF) is an improvement of the SMF because it features two independent but interconnected parts. A damping mechanism links the parts, contributing to reduced vibrations. This damping mechanism also helps safeguard the transmission system.

The downside is that this flywheel variety is more complicated, hence more costly to repair and replace.

A dual-mass flywheel

Billet Flywheel – High Performance

This is a sturdy and durable type of flywheel typically designed for high-performance cars. It is termed as a ‘billet’ because it is a solid block of metal. There are different types of billet flywheels, including billet steel flywheel and billet aluminum flywheel.

A billet flywheel

High-Performance Flywheel For Racing

This flywheel in the car is specially identified for high-level performance. It is common in racing cars and other high-performance cars. Since the goal is to accelerate faster, this type of flywheel is lightweight but very strong.

Sprung Hub Flywheel – Superior Shock Absorption

The sprung hub flywheel incorporates a spring or damper for enhanced shock absorption. The springs absorb engine vibrations and noise before torque is transferred to the transmission input shaft.

Flywheel Manufacturing Basics: The Considerations To Make

When looking for the best flywheels, several considerations apply, including the material and processing method. CNC machining and heat treatment are at the top of that list.

ProleanTech is ready to be a partner in your machining project for flywheel parts. Get a quote for your upcoming project to start.

Selecting The Ideal Flywheel Material

The choice of flywheel material depends on the specific application. Choosing the material is part of the CNC machining process, as this guide highlights: CNC Parts Life Cycle Explained.

Cast iron flywheels are cost-effective, wear-resistant, and easy to cast. They are perfect for heavy-duty use. However, they are limited to cars that operate at less than 6000 rpm.

A cast iron flywheel

Aluminum flywheels are lightweight and, therefore, ideal for faster accelerations. They have a lower moment of inertia that supports timely response. Furthermore, they are relatively affordable and easy to install. However, their heat resistance is relatively low.

An aluminum flywheel

Steel flywheels are stronger than iron and aluminum and suitable for high-RPM car engines. Trucks and racing cars typically use this type of flywheel because of a balance of weight and strength.

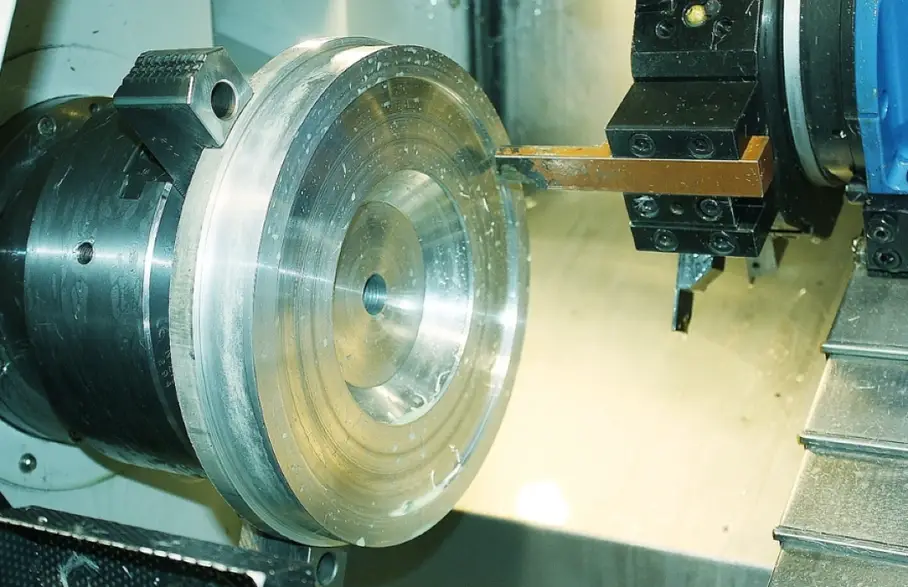

Choosing A Manufacturing Method – CNC Machining And Others

Choosing the best provider for CNC machining or other manufacturing services is important for the desired accuracy and precision. CNC machining is an excellent option for quality customized flywheels in cars.

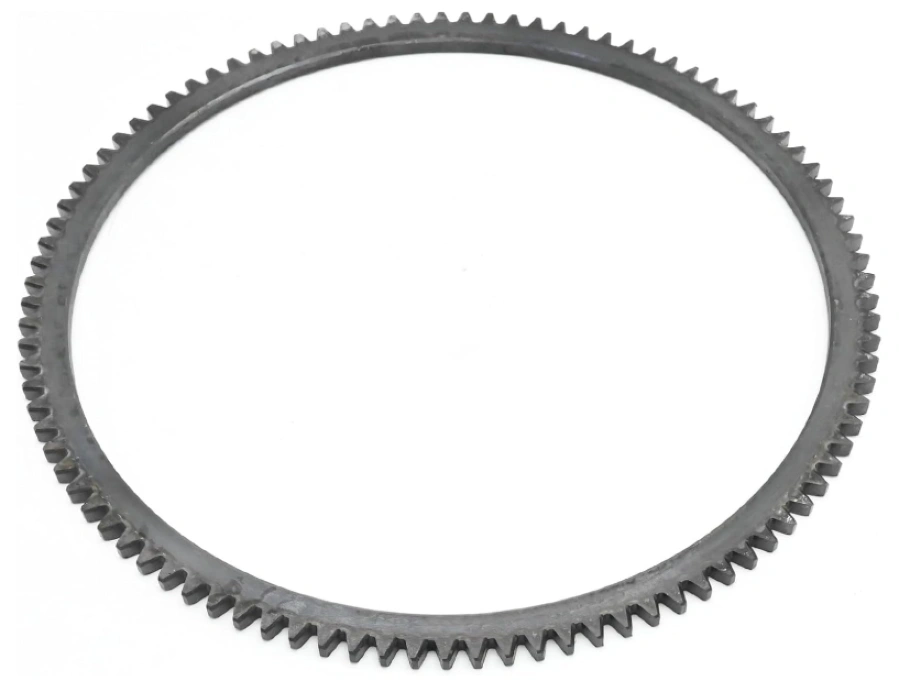

ProleanTech offers CNC machining services that include CNC drilling, milling, and turning. We can professionally customize flywheels by CNC machining parts like ring gear and mounting holes.

A ring gear of a flywheel

That includes giving the product the best surface outcome. Read about CNC roughing vs. finishing to get an idea of the different possible finishes.

If you are looking for faster production than CNC machining, then consider casting.

Surface Treatment Of The Flywheel

Surface treatment is a common process in flywheel manufacturing that is related to custom CNC machining. This process may involve heat treatment and surface coatings depending on the performance requirements of the parts.

These post-processing steps are crucial for cars meant for harsh driving conditions, such as coastal areas. Flywheels may be prone to rusting unless they are designed to counter this natural problem.

Rusty flywheel

In Conclusion

After this coverage of the flywheel in the car, we hope you are now more informed. We have outlined how this component works, its main functions, and the materials used in manufacturing.

The purpose of a flywheel in manual cars is invaluable, as it provides safety, comfort, and efficiency. Repairing and replacing it is expected due to common wear and tear issues. Upgrades may also be necessary to enhance a car’s performance.

Are you looking for the best CNC-machined flywheels for cars and need a reliable partner for this service? Your search stops at ProleanTech, a company that promises and delivers.

Contact us now for flywheels for all car brands.

FAQ

What is the flywheel connected to?

The flywheel is connected to the crankshaft with the clutch assembly (for manual cars) or torque converter (for automatic cars) as the interface.

How much does it cost to replace a flywheel?

The cost to replace a flywheel can vary a lot based on flywheel material, car type, and labor cost.

Is changing a flywheel a big job?

Yes, changing a flywheel is a big job that requires skills and specialized tools. Accessing the flywheel means removing the transmission shaft first, which is a demanding process.

What are the symptoms of a bad flywheel?

The common symptoms of a bad flywheel include rattling noises from the transmission, a burning smell when the clutch is engaged, the car not accelerating as expected, and problematic gear-shifting.

Can you drive a car with a bad flywheel?

Yes, you can drive a car with a bad flywheel, but it is not advised because this can cause serious damage to the transmission and clutch systems.

How do I know when my flywheel needs replacing?

You will know a car flywheel needs replacing if visual inspection reveals wear and cracks. Also, excessive vibrations and problematic gear shifting may suggest the need for a flywheel replacement.

How long will a bad flywheel last on a car?

The duration of a bad flywheel in a car varies. Upon the first sign of problems, the flywheel can fail even within a few weeks. It is important to solve the problem immediately to avoid more serious damage.

Does a bad flywheel make noise?

Yes, a bad flywheel produces noise, usually of clunking or rattling nature.

How much is a clutch and flywheel replacement?

The cost to replace a clutch and flywheel varies depending on the car type, labour cost, and quality of the clutch/flywheel.

0 Comments