The simple answer to the question, ” What is the chassis of a car?” is that it is the backbone of the whole vehicle system, to which are attached all mechanical parts, such as the engine, steering, frame, wheels, exhaust manifold, and suspension system.

A car chassis can also help to distribute the weight of the overall vehicle in a symmetrical way by systematically attaching the vehicle components and ensuring the vehicle’s structural integrity.

Top-quality car chassis are crucial for your business success and customer satisfaction, and they will be your business’s ultimate source of rapid growth. We will provide the data to help you select the right material for your automotive chassis, covering its types and components crucial for your industry’s success.

We will also discuss the future trends in this industry, including the importance of the right car chassis manufacturers like ProleanTech. This will ultimately help you make a calculative and informative decision, which could lead to rapid growth and success compared to your competitors.

Functions of an Automotive Chassis: The Backbone of Reliability

Functions of an Automotive Chassis

Understanding the functions of an automotive chassis is crucial for your business success. If you don’t know the exact functions of an automotive chassis with deep analysis, it is crucial for increasing your customer satisfaction and, ultimately, the success of your industry. Misunderstanding might lead to customer dissatisfaction and business loss.

The functions of an automotive chassis are:

Balancing with Structural Support: Source of Attachment of Different Car Components

The car chassis provides rigidity to the whole vehicle structure as it is responsible for ensuring the maintenance of structural stability and ensuring that all materials, such as the wheels, brakes, suspension system, engine system components, and transmission system, are attached to each other.

Weight Distribution

Car chassis also helps to ensure the weight distribution between the front and rear axles, which ultimately helps to handle the car more smoothly.

This will give the customer a smoother and more luxurious experience, which will be the ultimate source of increasing your business conversion rate.

Force Distribution

A car chassis also helps reduce a vehicle’s load or force by redirecting it, using crumple zones, or deforming it when applying acceleration, instant or forced braking, or in an accident.

Good-quality car chassis ensures that your customer faces a very low risk of damage in case of an accident or the effect of instant braking or acceleration.

Power Transferring

Another function of the car chassis also includes transferring energy from the car’s engine to its wheels, which ensures smooth working and delivery and an excellent customer experience.

Noise, Vibration, and Harshness (NVH) Reduction

One of the major functions of car chassis also includes reducing noise, vibration, and harshness of your vehicle, collectively called NVH reduction, which ultimately ensures the smoothness and comfort of any vehicle for your customers.

——————————————————————————————————————————-

Also Read: Learn how Metal Injection Molding vs. Die Casting compares to choose the best manufacturing process for your automotive chassis needs!

Try Prolean Now!

Structure of Car Chassis Components/Parts: That Impact Performance and Cost

Structure of Car Chassis Components/Parts

The car chassis structure and components are usually the same, but they might be different in some cases due to specific requirements or circumstances.

A good quality chassis allows you to save long-term costs and improve the performance of your industry-manufactured vehicles. Here, car chassis components/parts have been discussed in detail that might be helpful to give you the best idea about them:

Frame Rails

Frame Rails

Frame Rails are longitudinal beams made of steel or aluminum. They bear the load of the chassis and ultimately support the vehicle.

Suspension System

Suspension System

A vehicle’s suspension system is a collection of parts that links the wheel to the vehicle and allows motion between them. The suspension system also ensures a stable connection between the vehicle tires and the road surface, which ultimately results in smooth handling and movement of the vehicle on the road.

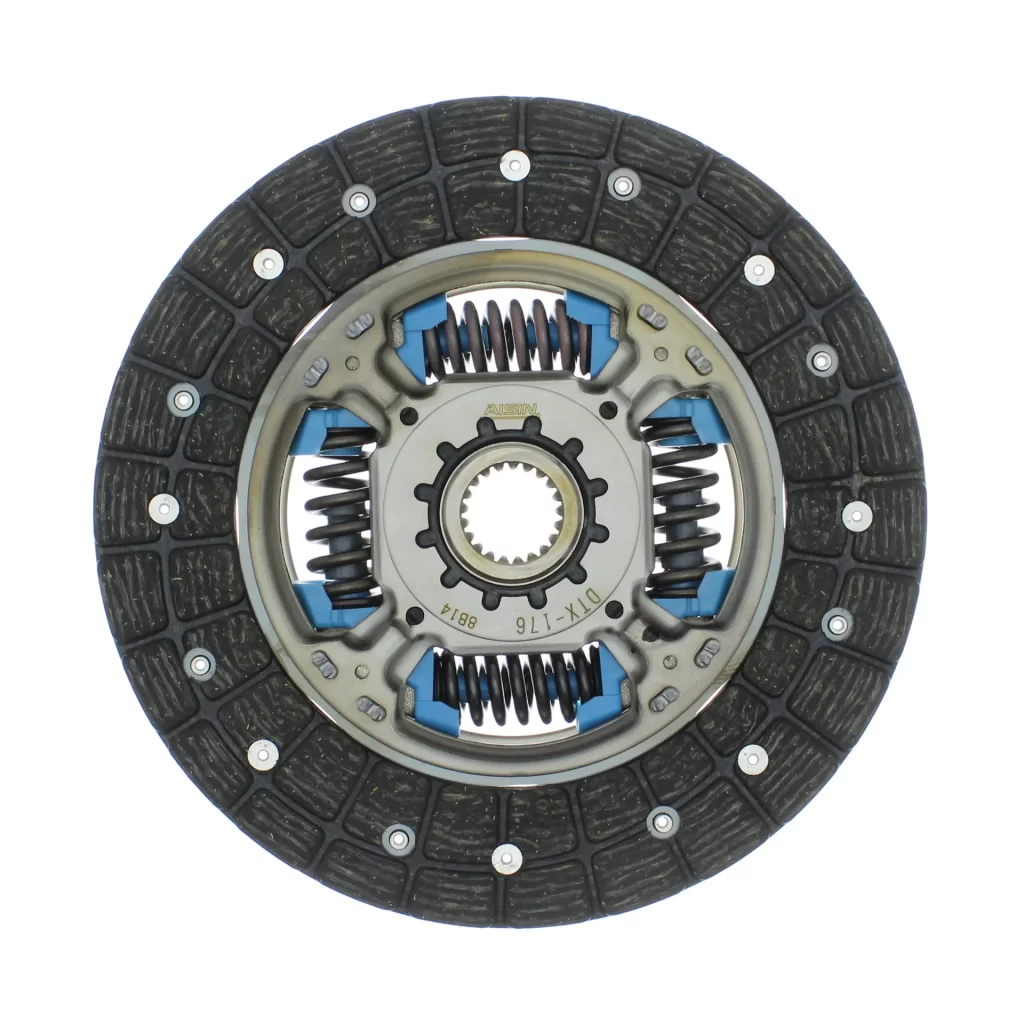

Clutch

Clutch disc

The clutch is a part of a suspension system that ensures the connectivity between the crankshaft and the transmission of the vehicle. This is ultimately the source of changing the gears smoothly and prevents the movement of the vehicle while running on a road.

Cross Member

Cross Member

Cross members are horizontal structural components of the suspension system that help to join the frame rails. They are very rigid and hard materials that help vehicles support their structure and provide a valuable addition to increasing their strength and surety with the engine and transmission system.

Car Gearbox

The car gearbox system, also known as the transmission system, is responsible for vehicle movement from one point to another. It works by transmitting the energy of the car’s engine to the wheel and controlling the movement of a wheel at different times when this action is needed.

Rear Axle

Rear Axle

The rear axle is a component of the chassis that delivers the power from the transmission system to the driving wheels. It also helps support the rear wheels and car suspension parts, which ultimately enable the vehicle to move and change direction.

Braking system

Brake System

This system is usually mounted to the car chassis and is responsible for stopping the vehicle’s movement. It uses friction energy to convert the wheel’s rotational energy into heat energy.

Try Prolean Now!

Types of Chassis: Which One Fits Your Business Needs?

Types of Chassis

Choosing the right type of car chassis is crucial for your industry success, and ProleanTech gives you this opportunity to find the chassis that might be best for your business success.

There are four types of chassis have been discussed, and we have to know which type of chassis is best fit for which kind of industry:

Ladder Frame Chassis

Ladder Frame Chassis

A ladder frame chassis is a traditional car frame design that consists of two parallel frame rails supported by smaller ones. As the name implies, this car chassis has a distinctive ladder-like structure. The sturdy and robust foundation that the ladder frame chassis design gives the vehicle supports the suspension and other essential parts of the car chassis.

Advantages

A ladder frame chassis is sturdy and appropriate for large, load-bearing vehicles like trucks and trailers. It is also simple to build and assemble, giving the car excellent structural stability.

Drawbacks

Because of its weight, the ladder frame chassis is inappropriate for high-performance, lightweight cars and needs better torsional ability.

Monocoque Chassis

Monocoque Chassis

The monocoque chassis design, sometimes referred to as the unibody design, combines the car frame and chassis into a single unit. Most contemporary cars, including sedans, hatchbacks, and SUVs, have this sort of chassis as standard.

As a result, the monocoque chassis design offers remarkable strength, rigidity, and crash resistance in addition to visual appeal.

Advantages

Its advantages include high torsional rigidity, improved durability due to the fused architecture, and efficient collision energy absorption and distribution because of the monocoque design.

Drawbacks

Monocoque chassis are expensive to produce because of their fused design, which may make repairing parts challenging.

Backbone Chassis

Backbone Chassis

Because it resembles the human backbone, the backbone chassis is also known as the central backbone or central tube design. This chassis style features a hollow cylindrical tube connecting the front and rear axles and suspension. It is the preferred design for off-road vehicles because of its excellent torsional toughness.

Advantages

The backbone chassis provides high torsional toughness and the vehicle’s robust and sturdy basis. It is great for passenger automobiles and off-road vehicles.

Drawbacks

Its drawbacks include that it gives expensive manufacturing costs. Its problems with the driveshaft compromise the chassis as a whole.

Tubular Chassis

Tubular Chassis

Tubular chassis, also known as space car chassis frames, are made up of a series of networks of tubular elements that combine to form a three-dimensional structure.

They are frequently found in race, lightweight, and high-performance cars. Additionally, the tubular chassis represents the traditional ladder frame chassis in three dimensions.

Advantages

The advantages of the tubular chassis include a superior strength-to-weight ratio, crash resistance, and increased design freedom and customization for cars with lightweight criteria.

Drawbacks

One drawback included that its intricate design makes building difficult.

——————————————————————————————————————————-

Explore CNC machining, its complete process, benefits, and diverse applications to discover how it transforms automotive manufacturing!

Try Prolean Now!

Top Chassis Manufacturers and Why Partnering with the Right One Matters

Choose the right car chassis manufacturers who know your industry goals and how to align with them to achieve short-term success and increase your business’s conversion. ProleanTech has the ISO 9001:2015 certification and a large number of skilled engineers to make chassis for industry vehicles.

We are experts in producing parts for any industry, especially for the automotive industry, which includes car chassis, using the die casting technique. You can also avail of our CNC machining service for this purpose.

We ensure the delivery of custom parts manufactured in 30+ countries, with the opportunity to make custom parts for your industry within one day. If you still have any problems or queries related to our services and want to discuss your project first feel free to contact us now.!

FAQ’s

What are the most commonly used metals used in car manufacturing?

Steel, Aluminium, Zinc, platinum, and many other metals are used in car manufacturing.

Are car frames the same as car chassis?

No, the car frame is the structural base of a car, and the chassis includes the frame plus all essential components like the engine, transmission, and suspension.

Can a car chassis be repaired?

Depending on the damage, it can often be repaired by skilled professionals using specialized tools.

Which types of car chassis are used for races?

Monocoque chassis is used for lightweight and aerodynamics, and space frame chassis is for high strength and flexibility.

0 Comments