Aluminum extrusion brackets and enclosures are indispensable in structural and electrical applications. For instance, a bracket serves as a secondary member that supports objects such as shelves to walls. Even though it appears to be similar to a fastener, a bracket does not join parts fast: screws or bolts are employed to join the bracket to other parts.

Brackets also give support and stability. Some gusset brackets connect plates to diagonal members. Their design allows them to support more weight than other parts of the structure. In addition, it’s cost-effective to use sheet metal fabrication to manufacture aluminum angle brackets, and enclosures are typically simple, geometrical, or symmetrical. In most cases, brackets are formed by using a flat and long piece of sheet metal known as the blank. For instance, if you bend the angle of a flat rectangle by 90° an L-shaped aluminum bracket will be produced.

Do you need custom aluminum extrusion brackets or enclosures? Prolean Tech is a leasing aluminum extrusion China that specializes in sheet metal prototyping with solutions fitting every kind of requirement. This guides you through bracket types, design guides, and standards for aluminum enclosures and brackets.

What are Aluminum Extrusion Brackets and How Are They Used?

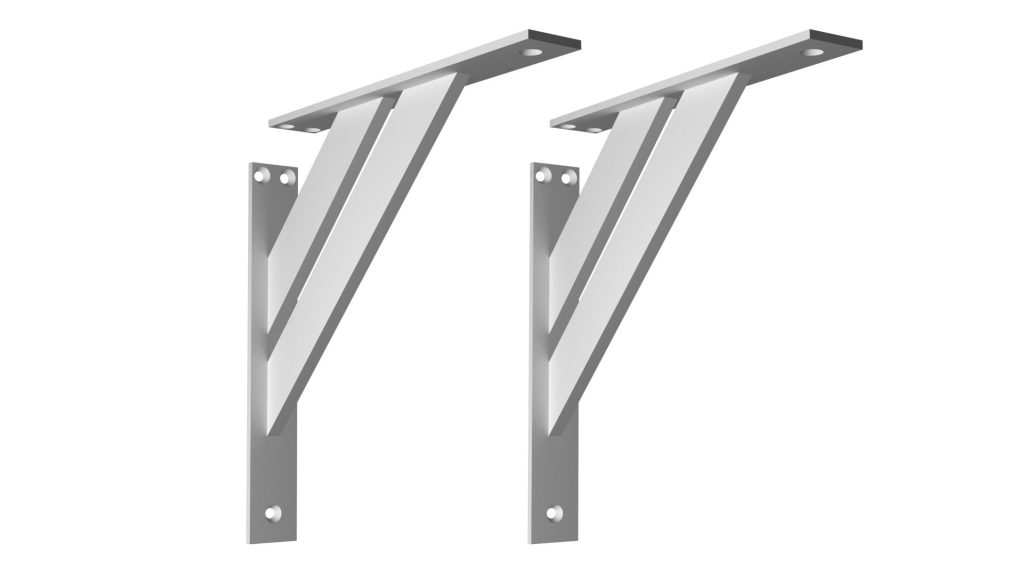

Aluminum Extrusion Brackets

Aluminum extrusion brackets are ideal fastening elements. They serve as a link between two separate objects. In architecture, aluminum brackets refer to the ancillary works that join structures, such as parapets or eaves to walls. In engineering, they support objects such as shelves, counters, floors, furniture parts, and hanging TV sets.

L-shaped aluminum brackets are popular. They come in various forms and sizes. Traditionally, the vertical part of the bracket is mounted on a wall or a large panel, and the horizontal portion is fixed to other objects such as shelves and other fittings. These are typically used as aluminum fence brackets. (Get more insights about aluminum extrusion applications).

A large number of aluminum brackets have openings – threaded or non-threaded to accept screws and bolts. Aluminum extrusion brackets can be purely utilitarian however, these can also be ornamental in their design. Because aluminum brackets are usually exposed to the public eye, they may contain some kind of ornate work or even a polished gold appearance.

Try Prolean Now!

How are Aluminum Brackets Made?

Aluminum Bracket Design

Aluminum extrusion brackets can be fabricated through casting and Computer Numerical Control-CNC machining. Nonetheless, for simple designs, sheet metal fabrication is very efficient. The most common process in manufacturing aluminum brackets is Sheet Metal Bending. During this stage, a brake machine bends the metal up to 120°. Soldering is essential because most brackets contain at least one curved piece. (Read about aluminum extrusion process). Before bending, you must fold the aluminum sheet to the desired shape with tools like laser cutting or plasma cutting. Punching machines creates holes for screws, welding may be used to connect gussets or other additions.

When it comes to dimensional, and tolerance aluminum brackets having standard sizes, then CNC machining can be optimum. Because you can incorporate elaborate features and fine joints into the bracket to improve your production efficiency.

Best Materials for Aluminum Brackets and Enclosures

Aluminum is a popular metal for brackets and enclosures. However, you can also exploit steel, copper, bronze, titanium, and brass to fabricate fence brackets. Among all the mentioned materials, aluminum usually appears economical and offers good machinability. Moreover, it is a lightweight, corrosion-resistant, and pliable material. The choice of bracket and enclosure material may be dictated by load bearing, finish, cost, and structural considerations.

Different Types of Aluminum Brackets

There are differing aluminum extrusion brackets usually used for different functions and structures featuring unique characteristics. Each type has different designs and serves an ideal purpose for a specific application.

L-Bracket

L-Shape Aluminum Bracket

The L-bracket is a comparatively basic bracket type with a 90° angle. It joins the horizontal and vertical members; for example, the shelves fixed on the walls; therefore, it is used for general support.

U-Bracket

Aluminum U-shaped Bracket

The U-bracket is bent along two axes to create a U-shaped profile. It allows objects to be held in place by engaging their flanges. U-brackets are ideal for installing objects that lie side by side or for suspending horizontals one below the other.

Z-Bracket

Aluminum Z-shaped Brackets

The Z-bracket employs two bends, to create a Z shaped cross sectional profile. It links offset facings. One is formed by bending one flange inwards, while the other is bent outwards. Z-brackets are useful for the support of flat surfaces that are closely placed with a small gap in between.

Gusset Bracket

Gusset Aluminum Angle Bracket

A gusset bracket improves on the previous option by adding a triangular metal piece between the horizontal and vertical sections. The triangular gusset is either welded or made from the same aluminum sheet and offers good support in load-bearing applications.

Aluminum Joist Hangers

Aluminum Joist Hangers

Aluminum joist hangers are used to fix wooden joists to beams, and walls, construction that would require support. These hangers are quite weightless but durable and non-corrosion which makes them optimal for indoor and outdoor use. Standard sizes of aluminum joist hangers are available in length of 3-18 inches, width of 1.5-5 inches, and thickness of 0.05-0.25 inches.

Aluminum Suspension Hooks

Aluminum Suspension Hooks

Aluminum suspension hooks are intended for the suspension of various items from ceilings or beams. These hooks are normally used for hanging light fixtures, pipes, or other equipment. Aluminum suspension hooks have length dimensions of between 3 to 10 inches, width of between 1 to 2.5 inches, and thickness of between 0.05 to 0.25 inches.

Aluminum handrail brackets

Nickel Finished Aluminum Handrail Bracket

Aluminum handrail brackets are hardware components used to secure handrails to walls and posts in vertical structures. These brackets come in various designs and sizes, with angles typically ranging from 90° (for straight installations) to adjustable angles for custom installations. Common sizes for aluminum handrail brackets include lengths from 2 to 6 inches, widths of 1.5 to 4 inches, and thicknesses ranging from 0.05 to 0.25 inches.

Try Prolean Now!

Laws and Agencies Concerning Aluminum or Metal Enclosure

For aluminum and other metal enclosures, a few laws and regulations have to be followed to provide safety, quality, and environmental regulations. They are produced and used under the regulation of several agencies and standards.

ISO 9001

ISO 9001 is an international standard for Quality Assurance/Quality Management Systems. Most aluminum extrusion companies undergo the ISO 9001 certification to show a particular quality, process, and customer orientation.

OSHA or Occupational Safety and Health Administration

OSHA provides safety measures for employees in the United States workplaces, and aluminum and metal enclosure manufacturers cannot afford to neglect the guidelines provided by OSHA, especially in handling dangerous material and equipment.

FDA (Food and Drug Administration)

The FDA poses few restrictions on specific aluminum alloy grades and metal casings generally used in food storage and medical device manufacturing. Manufacturers must have to meet FDA regulations. This ensures their products are safe for use in kitchens and healthcare facilities.

California Proposition 65

Proposition 65 is a law found in California that makes it mandatory for businesses to display a warning statement on products that typically comprise chemicals. These are on the state’s list of chemicals that may lead to cancer, birth defects, or reproductive harm. The regulation may apply to aluminum and metal enclosures if they are assembled with lead or cadmium.

New York State Department of Environmental Conservation or simply NYSDEC

The NYSDEC regulates aspects of hazardous substances in products, including aluminum or metal casing. These regulations have to be met to prevent pollution, especially as concerns heavy metals and other hazardous materials.

Massachusetts Toxics Use Reduction Act (TURA)

The TURA law requires companies in Massachusetts to disclose their use of toxic chemicals, for instance, lead or cadmium. TURA ensures that producers of aluminum and metal enclosures limit the use of hazardous substances in their products.

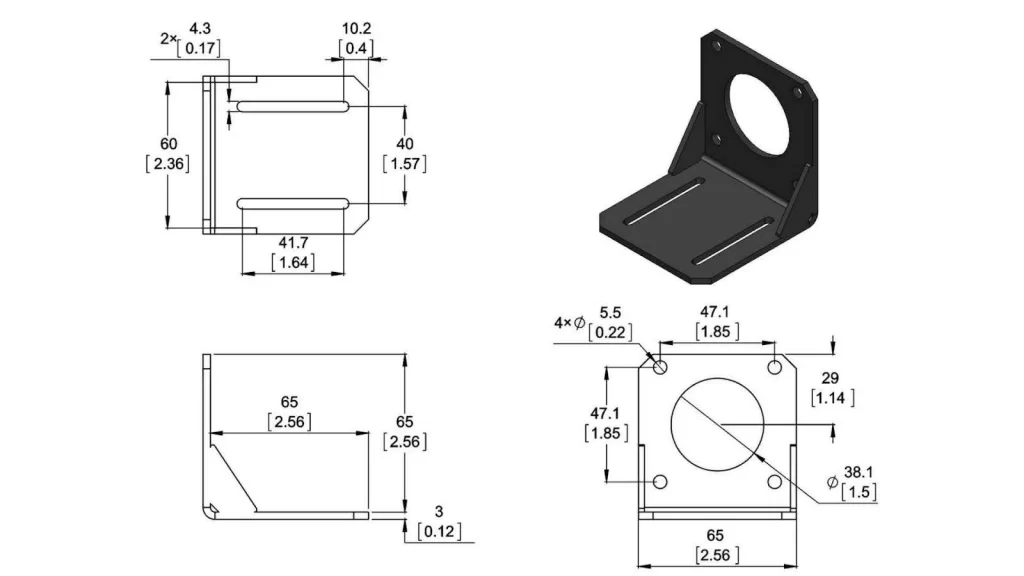

Designing Aluminum Sheet Metal Bracket

CAD Aluminum Bracket Design

Aluminum extrusion brackets can be designed in CAD software with great efficiency; however, some factors are important. Aluminum L-brackets are typically made at a 90-degree angle in their construction, but other angles up to 120 degrees can also be ordered by the manufacturer. What may be necessary to state here is that when employing thicker gauges or lower ductility of aluminum, certain angles may not be achievable.

Even though L-brackets are less complicated to manufacture, U- and Z-brackets are slightly more challenging in terms of design. For instance, a brake cannot make multiple bends in aluminum if one flange extends far enough to block the clamping bar. If the parallel sections of the U- and Z-brackets are kept as short as possible, bending should be relatively easy.

Aluminum extrusion brackets must have specific holes for screws and bolts. Aluminum, unlike wood or plastic brackets, needs specific hole dimensioning for a given fastener size/ So, adjust the hole diameter to the size of the fasteners being used. In case it is impossible to use a nut, threaded holes may be required.

In addition, welded parts add to the overall costs of production. Therefore, think of an aluminum bracket that can be made in one piece without having to weld. Every hole or custom cut increases cost but at the same time, machining enables designers to create intricate shapes, patterns, and appearances for specific uses.

Prolean Tech is a premier prototyping and on-demand manufacturing company for low-volume to high-volume extrusion services facilities. We specialize in aluminum sheet metal brackets and offer custom designs to meet any specifications. For more information on how we can custom design the aluminum bracket that you need, please get in touch with Prolean Tech today for a quote.

0 Comments