Custom sheet metal cut materials to required sizes to make different products. Look around, and you will find sheet metal products all around in everyday use. Nowadays, sheet metal cutting is used in just about anything from beverage cans and cookware to auto frames and exhausts. Its value is universal across industries and particularly relevant for low-volume production.

In this article, we will provide you with an overview of custom-cut sheet metal. Moreover, we will describe the primary techniques, applications, and benefits. In addition, the appropriate materials and surface coatings are to be used during fabrication, will described. Read on for more information on custom sheet metal fabrication.

What is Custom Sheet Metal Fabrication all about?

Custom Cut Sheet Metal Parts

Custom sheet metal manufacturing entails the formation of a product from sheets. By employing sophisticated techniques, the metal sheets are shaped, curved, shaped, and combined to shape a product. The manufacturing method creates products of specific cross-sections out of various metals.

In addition, the fabrication helps in different materials such as stainless steel, aluminum, brass, copper, zinc, etc. Sheet thickness typically lies between 0.006 and 0.25 inches. In general, thin ones are more versatile, and thick ones are used to handle heavy loads and strains.

Moreover, computer-aided design (CAD) is used to facilitate the development of sheet metal products. CAD tools make 3D models to gain accurate representations of an actual product. These models translate to G-code used in cutting, forming, and assembling metal sheets by machines. (Read more about sheet metal basics)

Three Key Custom Sheet Metal Fabrication Techniques

Different approaches are applied in custom cut sheet metal fabrication. Understanding these sheet metal machining techniques improves the resulting designs and performances. The following are the three common methods of sheet metal fabrication.

Cutting Custom Sheet Metal

Sheet Metal Shearing

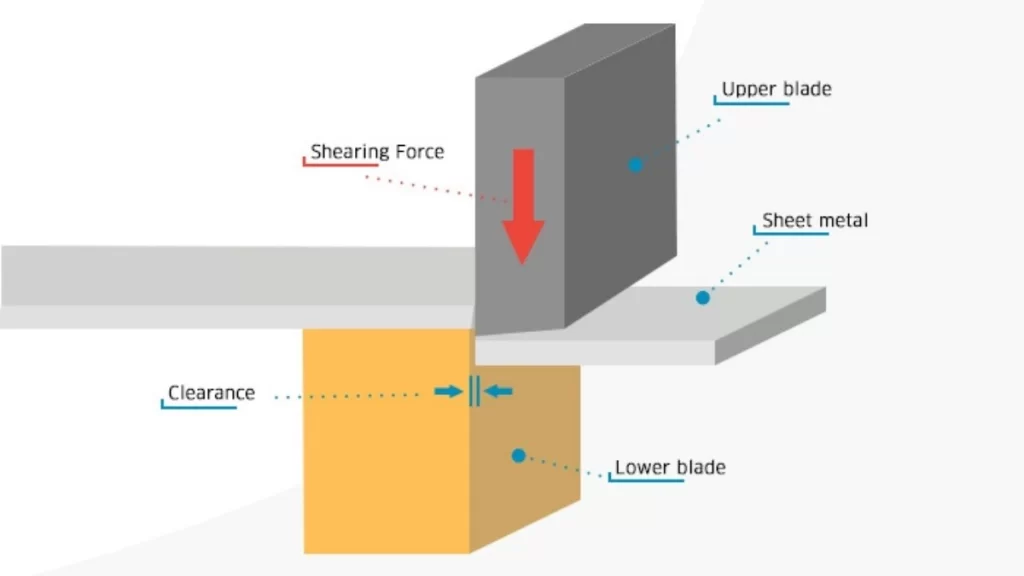

Shearing is often the primary operation of metal sheets cut to size. It’s done by forming flat sheets into a particular design. The tool choice usually depends on the project requirements. Cutting techniques are categorized into two groups: conventional milling with and without shear.

Cutting Without Shear

Nonshear refers to techniques of cutting operating without mechanical shear force. These processes employ heat, pressure, or abrasions in their ability to shear through metal sheets. The main techniques are laser cutting, plasma cutting, and water jet cutting which are suited for different metals and designs.

- Laser Cutting: Laser cutting uses a laser beam wand to cut and melt sheet metals. It is very precise and can make very complex shapes. It operates on metals for example stainless steel and mild steel by using gas. For instance, oxygen or nitrogen to clear melted materials and maintain cuts sterile.

- Plasma Cutting: Plasma cutting employs ionized gas to melt electrically conducting materials and metals. The method is optimum for materials such as aluminum and steel. It has a high cutting rate and accuracy to suit middle-thickness metals for commercial and special purposes.

- Waterjet Cutting: The waterjet cutting technique cuts sheets through high-pressure water with an abrasive garnet utilized to cut metal sheets. This multi-process technique is primarily used for chopping soft and hard materials inclusive of rubber and carbon steel. Moreover, it’s considered a green process compared to laser cutting, as there are no heat-affected zones observed in the cut zones.

Cutting With Shear

Shear cutting uses mechanical forces for a metal sheet cut to size. The intended category embraces techniques that utilize dies, punches; or presses to create the wanted cut. It’s among the most popular techniques in industries that deal with large metal stocks and embraces such tools as shears, punches, and saws.

- Shearing: In sheet metal shearing, processes, the mechanical force exploited to cut through metal sheets in straight lines only. It’s a swift and inexpensive way of scribing masses of materials such as brass or aluminum for instance. While being effective in mass production, shearing may cause edges to be sharp and may require post-finishing.

- Punching: Piercing is used to make shaped or round holes in thin metals through the application of force in the direction of the sheet thickness. It’s widely applied in industries needing exact-shaped cuts such as vehicle manufacturing industries. Punching is quite flexible and one can easily make different contours and different patterns provided or have a right-shaped die.

- Blanking: Blanking process cuts out a particular small part from a large sheet of metal by using a punch and die. A portion of the material is cut out, leaving only the “blank,” which is the finished product, and the rest is waste. Blanking is frequently applied to high-volume production because of its operational ease and ability to produce consistent and accurate products.

- Sawing: Sawing entails a saw blade to shape or slice the metal in the form of sheets or metal bars into thinner pieces. For cutting long stock material the horizontal band saw is beneficial, while for cutting or shaping small intricate pieces, the vertical saw is more helpful. Sawing is advantageous when it comes to cutting soft and hard metals into various shapes and sizes.

Try Prolean Now!

Sheet Metal Fabrication Forming Processes

General Sheet Metal Forming Techniques

Bending works by bending the material whilst maintaining its integrity. These methods are essential in developing sheet metals for several uses. The following techniques are usually applied in the forming of sheet metals.

- Bending: Bending is an efficient process in terms of operational costs for small to medium-scale production. It distorts the metal by applying pressure and bending it to the desired angle. For this process, press brakes and rolling machines are used. Additionally, bending has good compatibility with spring steel, copper, and aluminum 5052.

- Rolling: Rolling uses rollers to bend or thin sheets of metal. For planing it implies using a flat tool to shave a thin layer of material off the surface of a metal. The high-pressure rollers then reform the metal in a plastic manner. It can also be performed at or below room temperature(25 C) known as cold rolling or at high temperature referred to as hot rolling. Mainly, rolling is applied in creating components such as tubes, discs, and pipes.

- Stamping: Stamping is a cold working metal cut process. It involves cutting and forming operations to generate intricate forms rapidly. Stamping press and die are used in forming metals like aluminum, copper, and steel. Stamping is relatively fast and economical. Therefore, it’s most appropriate for mass production of the product. However, several design changes during the process have always been very cumbersome and expensive.

- Hemming: The hemming process forms a two-layered section by bending the edge of a sheet metal piece to the other side of the piece. This process typically occurs in two stages: shaping the metal to a V-die and afterward flattening the die. Hemming also provides extra support on the edges and makes the part look better. Nevertheless, dimensional variations may occur due to the material deformations being used.

- Curling: Folding gives sheet metal a round shape, turning it into a tube-like structure. This process is usually done in the three different steps of progressing and setting the curl. Curling increases the tensile strength of the part and smoothes the surface to reduce edge sharpness. Thus reducing dangerous physical contact.

Welding Processes on Sheet Metal Fabrication

Sheet Metal welding

The following are the main joining methods employed in fabrication to give a single integrated part from the sheet metal parts.

- Welding: Welding involves joining two metal sheets by heating and melding them together with a filler material. This process is common during the last operations of fabrication and may include SMAW, MIG welding, and TIG welding. All these techniques are used in different circumstances but all aim at creating a metallurgical bond.

- Riveting: Riveting is a mechanical fastening process in which a rivet is passed through two or more metal sheets with a hole and then made to expand to join the sheets together. The process is most frequently applied to metals such as aluminum and copper. There are two main types of riveting: cold riveting, for thin metal sheets and hot riveting for metals with thickness greater than 3mm like steel. Riveting produces strong, tightly fitting connections, perfect for non-ferrous metals.

MIG vs TIG Welding for Custom Cut Sheet Metal

When it comes to custom-cut sheet metal fabrication, choosing between MIG and TIG welding depends on several key factors. Below is a comparison of the two welding techniques to help you decide the best method for your specific needs.

|

Parameter |

MIG Welding |

TIG Welding |

|

Power Source |

Uses only DC power |

Uses AC or DC, with AC suitable for aluminum |

|

Material Compatibility |

Suitable for various metals, ideal for thinner sheets |

Ideal for thicker metals with precise control |

|

Electrode Type |

Uses consumable electrodes |

Uses non-consumable tungsten electrodes |

|

Shielding Gas |

CO2, helium, argon, or oxygen |

Primarily argon, with mixtures for specialized tasks |

|

Cooling System |

Air-cooled torches |

Water-cooled due to higher heat generation |

|

Weld Quality |

Faster but lower finish quality |

Slower but provides a cleaner, aesthetic finish |

|

Productivity |

Faster process, suitable for larger projects |

Slower, detailed process for high-quality finishes |

|

Cost |

More cost-effective for larger runs |

More expensive due to higher detailing and quality |

DFM Guidelines For Sheet Metal Design

Design for Manufacturability (DFM) is a virtual design concept intended to prevent bad design decisions and enhance product manufacturing processes. In custom sheet metal fabrication, adhesion to the DFM standards guarantees that the part is producible with ease hence cutting on cost and time.

7 Key Factors in Sheet Metal Design

Here is a checklist, you can use when designing low-volume sheet metal prototypes.

Hole Radius

Avoid small holes in the design. Because they need small punches to make and often tend to crack. A hole diameter should be greater or equal to the material thickness to provide the necessary strength and precision.

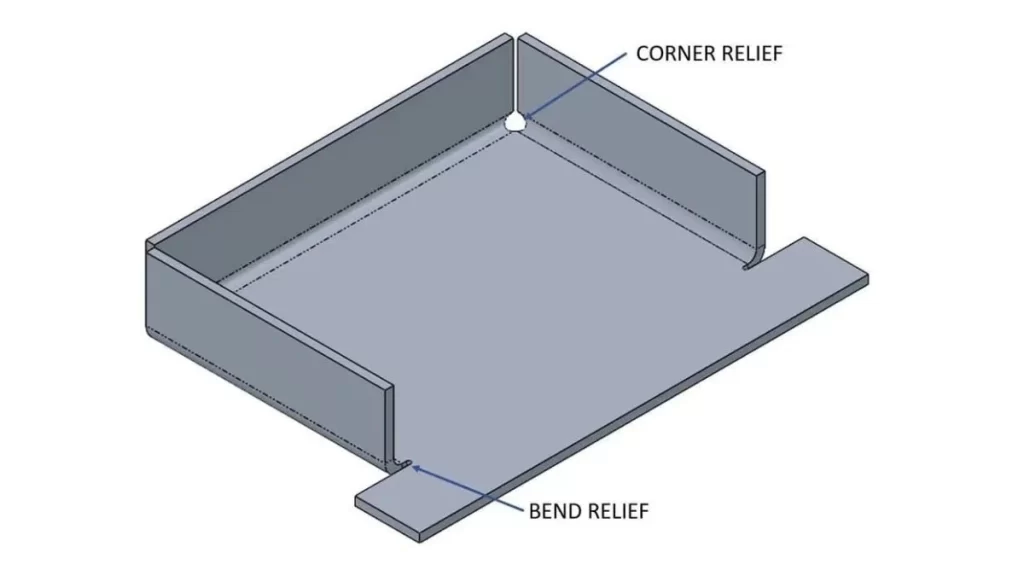

Bend Relief

Bend Relief

Bend relief means small localized depressions normally provided in the metal sheets to facilitate the bending operation. This reduces the possibility of tearing or cracking at the point of bend operation while keeping the design intact.

Hole to Bend Clearance

There must be a minimum distance of 1.5 times the thickness of the sheet plus the bend radius between any two holes and bends. This spacing allows for bending without deformation to take place.

Sheet Metal Bend Radius

The minimum bend radius should be set up depending on the allowable flexibility of the material as well as the tools at hand. For flexible metals, the achievable radius is smaller than for other metals. However, the minimum radius generally depends on the tooling.

Flange Width

The recommended flange width of a sheet metal being used in a design should be at least four times the sheet thickness. This way the appearance and design hygiene can be preserved alongside the strength and structural durability.

Try Prolean Now!

Advantages of Sheet Metal Manufacturing

The major advantages of sheet metal manufacturing include the following:

Lightweight parts manufacturing

Sheet metal cut fabrication is efficient and useful in cutting custom cut aluminum sheets and light gauge parts. Aerospace and automotive industries need lightweight engine parts, for which custom sheet metal fabrication provides quality products. It increases aircraft and automobile fuel efficiency while maintaining production efficiency, simultaneously.

High Technique and Material

Custom sheet metal fabrication gives many possibilities for personalized designs. The options available are also vast; you can get custom cut steel sheets and custom cut stainless steel sheets, and products. Depending on the application of your end product – be it structural members, enclosures, or precision parts – the choice of material is crucial.

Efficiency and Accuracy

Sheet metal technology improves fabrication as it enables rapid prototyping with increased accuracy of the required models. For instance, some of the laser cutters can make cuts with widths of 0.0005 inches. Nearly all sheet metal processes are computer numerically controlled, reducing human intervention and guaranteeing that the products are relatively non-deformed.

List of Sheet Metal Fabrication Materials to Use

A diverse range of materials is compatible with sheet metal engineering, including:

- Stainless Steel

- Hot Rolled Steel

- Cold Rolled Steel

- Pre-Plated Steel

- Carbon Steel

- Aluminum

- Copper

- Brass

These materials can be used to create manifold elements and products including automotive parts, electronic covers, construction elements, etc.

Surface Finishes for Sheet Metal Fabrication

Surface finishing is a fundamental aspect of custom-cut sheet metal, providing both functional and aesthetic benefits. Here are some common surface finishes used in sheet metal fabrication:

- Powder Coating: Powder is applied and then set hard by heat to provide a hard-wearing and protective coat.

- Bead Blasting: Small beads are blasted against the surface by high-pressure air to clean it and leave a rough surface.

- Brushing: One central use of abrasive brushes is to give a finely textured surface that adds to the surface looks and consequently, makes it less susceptible to fingerprints.

- Electroplating: Electric current is used to deposit a layer of metal on the surface to improve its ability to resist corrosion and enhance conductivity.

- Anodizing: Aluminum surfaces are transformed through the electrochemical process that adds tough, corrosion-proof, and dyeable coatings.

- Laser Engraving: A focused laser puts designs or texts onto the metal to decorate and engrave with an added level of detail.

- Screen Printing: The design, logo, or label is made on a metal surface by using ink which is placed on a mesh screen.

Best Practices of Sheet Metal Manufacturing

Here are some essential design tips for manufacturability in sheet metal fabrication:

Wall Thickness

In the case of sheet metal fabrication, each component should have a uniform thickness throughout, because it is created from a single metal sheet. In general, the parts can be made in thickness from 0.9mm to 20mm. In laser cutting, the preferred metal thickness is from 0.5mm up to 10mm. While In sheet metal bending the recommended metal thickness ranges from 0.5mm up to 6mm.

Holes and Slot Orientation

While designing a sheet cut-part, one should take into account the diameter of holes and slots, which should be not less than the material thickness. There must be adequate space between the holes. They should not be placed on the circumference or edge of the sheet.

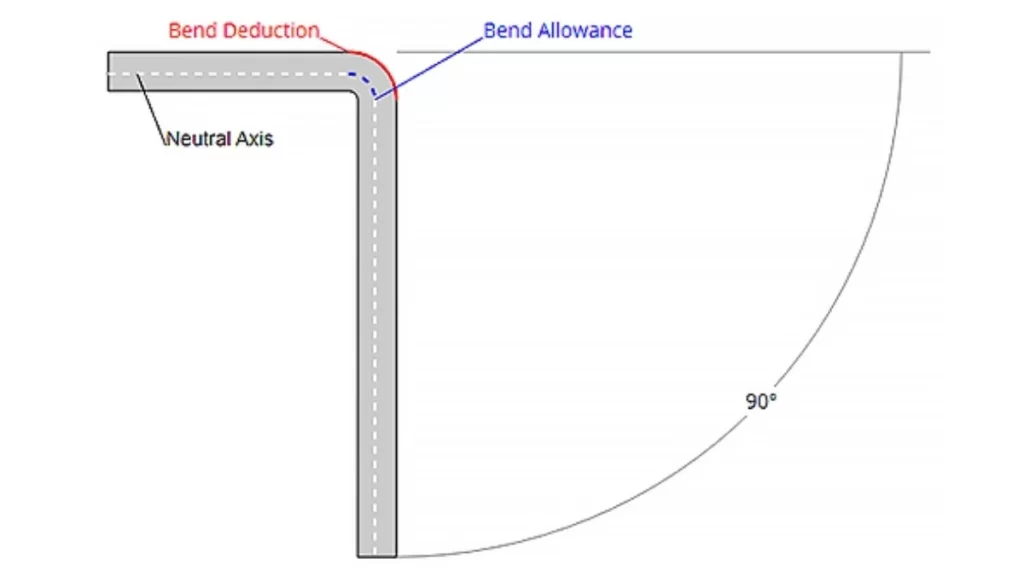

Bend Allowance and Deduction

Bend Allowance and Deduction

Bend allowance determines the additional length required for the material to make the required bends on a design. While bend deduction refers to the amount that usually needs to be trimmed off the length of the flanges for a balanced look. These two are important in the development of good flat patterns.

Bend Radii

The internal bend radius must be kept to the value equivalent to the material thickness used to eliminate the defect formation and distortion on the final product. The right orientation of a component and cost efficiency in sheet metal engineering are enhanced by the consistency of bend radii in the components.

Sheet Metal Fabrication Services of Prolean Tech

For an organization to work with a competent manufacturer to get quality sheet metal fabrication, it’s crucial to be transparent about design requirements and affordability. Manufacturing services provided by Prolean Tech are of high quality. We are an ISO-compliant company and as such we assure you of the standard quality prototypes or end products for your sheet metal fabrication. Comprehensive part inspection support is given to guarantee that only the best quality is delivered for your project. You can call or email Prolean Tech right now for instant sheet metal fabrication quotes and some feedback on your DFM results.

Conclusion

Custom-cut sheet metal fabrication is an indispensable manufacturing technique for large-run production. The method has many advantages such as increased work productivity, accuracy, and freedom to design lightweight parts according to the project’s needs. Further, it provides compatibility with a broad scope of materials and techniques. However, certain considerations must be taken into account for optimal outcomes.

FAQ’s

Q1. Common materials for custom cut sheet metal fabrication?

Cut-to-size sheet metal can be made from materials such as aluminum, carbon steel, and stainless steel. The following materials have the requisite characteristics that enable them to be utilized to fulfill different functions in various industries such as automotive, aerospace, and construction industries.

Q2. What is the typical thickness range for custom cut sheet metal?

Custom-cut sheet metal thickness is usually between 0.5 mm to 20 mm depending on the intended fabrication method. For example, when using laser cutting for sheet metal fabrication, pieces between 0.5mm and 10mm are most appropriate while bending processes can handle thicker pieces.

Q3. How does the design of custom cut sheet metal impact manufacturability?

Design plays a key role in the manufacturability of custom-cut sheet metal. The choices of species such as wall thickness, hole size, and bend radii must be optimized well to ease fabrication and minimize defect incidences during production.

Q4. What finishing options are available for custom cut sheet metal parts?

The cut sheet metal can be finished in several ways such as powder coating, anodizing, or electroplating. These finishing options improve the looks and functionality of the metal parts.

Q5. What measures does Prolean Tech take to have quality in custom-cut sheet metal fabrication?

At Prolean Tech, we offer custom-cut sheet metal fabrication services by employing new technologies and ISO-accredited procedures to ensure that every fabricated product meets the required quality standards. The company holds a rigid in-line inspection procedure to make sure that all the parts it produces are in agreement with the specifications and standards it sets.

0 Comments