Injection molding vs vacuum forming are prevalent manufacturing techniques. Both methods are applicable in large manufacturing settings. The deciding criteria involve material type, production speed, and equipment cost. The injection molding process uses a thermoplastic material injected into a mold of a desired shape. On cooling the material sets to the final shape. Vacuum forming, In contrast, entails heating the thermoplastic to a particular temperature but not tumbling it into a liquid. The material is then softened and fitted on a detailed mold.

Vacuum forming requires less initial investment than injection molding cost. However, vacuum forming seems to have shorter production runs in many circumstances. However, flexibility, and making changes in the design of the formed plastic are vacuum forming advantages. In this article, we will compare the strengths, weaknesses, and selection criteria.

How Does the Injection Molding Process Work?

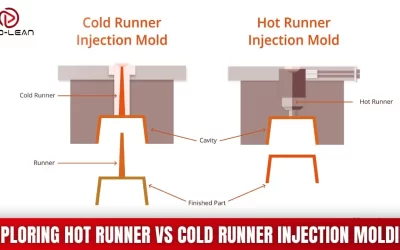

The plastic injection molding process begins with the pellets feeding into a hopper. The pellets then move into a barrel where they are heated to a liquid state. A big screw acts to advance this molten plastic and, apply pressure simultaneously. When the applied pressure is sufficient, a ram pushes the screw in the mold direction. Finally, the molten plastic is injected into a mold directly from the nozzle and through the runner gates.

Injection molding

The gates control the form of the final part made of plastic. A mold can be simple or complex. It can be used to create one part or many related parts at once. An injection unit closes the mold during injection and cooling, while an ejecting unit opens the mold. When cooled the mold opens and the part can be removed through the use of some mechanical means. Additional processes and injection molding finishes may be used for making parts meeting end needs such as gate trimming where necessary.

Try Prolean Now!

How Does the Vacuum Forming Process Work?

Vacuum forming starts by using a vacuum to hold a thin plastic sheet in position. When the sheet reaches its melting point, it is flattened out into a soft and more manageable material. After that, it is spread over the mold surface. The mold and sheet are pulled apart. So, the air between them is pulled out thereby forming a vacuum. The vacuum then tightens the plastic against the mold giving it a shape. On cooling the part is taken out and unwanted material is machined off from the casting.

Thermoformed components

Edge and corners are usually exposed to significant stretching. So, it’s optimal to use thicker materials in these areas. This can be achieved by using billow forming and plug assists to control the thickness. The inflates shape the plastic into a bubble before they subject it to the molding process. A plug assist provides the sheet with pre-stretching before vacuum pressure to allow better material distribution.

Material and Tooling Comparison Between Injection Molding Vs Vacuum Forming

Injection molding can accommodate several materials. Some common molding processes are rubber molding, liquid silicone rubber molding, and metal injection molding(MIM). In contrast, vacuum forming can only be used on thermoplastic material. The process is the same for using thermosets and thermoplastics because they can be reheated. It also supports glass-filled or fiberglass-filled polymers.

Both methods employ these familiar materials; acrylics, polypropylene, and polyethylene. Fire retardant or food-grade materials can also be used for either process as well as other specialty plastics. The product designers can choose materials according to their requirements for specific applications.

Vacuum forming employs convex or male molds or concave or female molds. In convex molds, the internal dimensions are emphasized, while in concave molds the external ones are reinforced. Injection molds are often made from secure materials like aluminum or steel, in combination with higher volumes and intricate geometries. Thermoforming usually requires cheap tools such as wooden models or aluminum cores. However, injection molding needs more rigid tools to achieve finer parts and higher quantities. Read more about Injection Molding Quality Control.

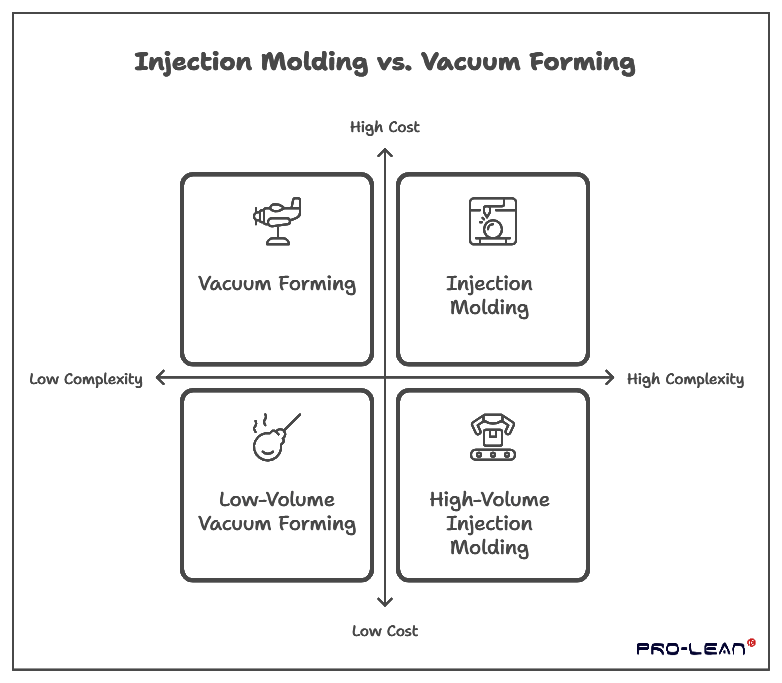

Injection Molding Vs Vacuum Forming: Complexity and Volume Comparison

In terms of complexity and volume comparison, injection molding is suitable for creating designs with thin-walled sections and small clearances. It provides better material control as opposed to vacuum forming which pulls the plastic in one particular direction. It can build shapes of complicated patterns such as solid objects like plastic fasteners. Therefore, vacuum forming is more restricted to hollow shapes such as panels.

Injection molding can co-mingle material, for example, silicone over-molded onto hard plastic. It offers a higher part consistency and is also beneficial for the large production volume of parts. Vacuum molds are the least expensive, and the manufacturing time of the molds is relatively less as compared to the injection molds.

Comparison Table Between Injection Molding Vs Vacuum Forming

Table 1. Showcases the primary difference between injection molding vs vacuum forming.

| Attribute | Injection Molding | Vacuum Forming |

| Suited for intricate designs | Yes | No |

| Allows for larger part designs | No | Yes |

| Suitable for large production runs | Yes | No |

| Poor design flexibility | Yes | No |

| Lower tooling cost | No | Yes |

Injection Molding Vs Vacuum Forming: Comparison based on Key Dimension

- Cost comparison: The IM requires a high initial investment in the tooling department. While Vacuum forming has comparatively low tooling costs.

- Speed comparison: The lead time for injection molding is longer in general. Vacuum forming is preferable in terms of time since it takes less time to perform. Lead time of injection molding is normally 12-16 weeks. Vacuum forming lead time is normally within 6-8 weeks.

- Volume comparison: Injection molding is vital for high-volume production requirements. Between 1 to 3000 units, there may often be additional costs to injection molding, but if parts go beyond three thousand, it becomes cheaper. In vacuum forming, the molds may wear out with time thus bringing down the life expectancy of the molds.

- Materials comparison: More material choices are possible with china injection molding than with vacuum forming. It supports chemical-resistant plastics, thermoplastic rubber, and antistatic plastics. Vacuum forming on the other hand uses PETG, PP, and PVC sheets.

Try Prolean Now!

Alternatives to Injection Molding and Vacuum Forming

3D printed parts

3D printing is a choice alternative to injection molding and vacuum forming. This process builds objects by applying layers according to a 3D computer model. 3D printing resembles injection molding in its handling of complex geometries. Each of the two techniques is capable of creating very complex shapes. Though for thermoplastic, more specifically for rapid prototyping, 3D printing or Vacuum forming is more applicable. These two methods are relatively faster and more efficient during the early stages of a product’s development.

Similarities Between Injection Molding and Vacuum Forming

Nonetheless, there are a few similarities between injection molding and vacuum forming. In both processes, heat is used on the thermoplastic materials. However, in injection molding, the material to be used is first heated to its melting point. In vacuum forming the thermoplastics are heated and softened but not up to the melting stage. Both methods also use thermoplastics to build parts for the end consumer. These similarities make either process appropriate for some manufacturing requirements.

How to Choose Between Injection Molding Vs Vacuum Forming

The following are determinants for making a better choice for optimal process selection between the two;

Consider Your Applications

So when it comes to injection molding and vacuum forming, consider the part’s end uses. In applications such as engine parts, transmission connectors, and intake manifolds, both techniques may be used. Similarly, aluminum can be used in car lids, doors, and front bumpers. Today., aluminum car bodies are becoming increasingly common.

Evaluate Raw Materials

Compared to injection molding, transfer molding offers a greater variety of plastic pellets, and the ability to vary mechanical properties, color, and surface texture. It is particularly useful if your project needs to feature different material properties at different locations.

On the other hand, vacuum forming usually restricts you to plastic sheets, made from ABS(In certain cases). However, if one wants to have a variety of materials, injection molding can be the right choice.

Examine Detail and Complexity

Injection molding is outstanding in delivering parts with fine features and close-dimensional control. It can form components with undercuts, through holes, screws, and bosses which vacuum forming cannot do since it employs single-face tooling.

If your design pattern is intricate or contains some internal geometries or other design complexities, then injection molding is the appropriate process.

Assess Cost Considerations

For low-volume production, or where close tolerances are not crucial vacuum forming appears to be cheaper. The tooling and production costs are relatively lower than injection molding. Nevertheless, if you want to produce 1000s of units at a time, injection molding will be economical, though the initial cost will be much higher, and the rate of production will be faster.

Determine the Type of Part

Finally, the type of part you want to design will determine your decision process. Injection molding appears to be a far more complex process, yet vacuum forming is the most efficient for creating simple geometry parts. For instance, the two processes can be used to produce polycarbonate helmets. However, in the case of the helmet shell, pressure forming is usually easier and cheaper than buying an injection molding machine.

Try Prolean Now!

Get Complex Parts Fast – and In Any Volume From Prolean Tech

The decision on the right manufacturing process is very essential while manufacturing complex parts. Design for manufacturing (DFM) support increases production outcomes even when it is provided in the early stages of the project regardless of the volume of parts required. A clear plan plus an adequate manufacturing partner plays a huge part in determining success in this market. As a worldwide producer of prolonged electronics, Prolean Tech has numerous production facilities and experience in providing high-per-shot precision injection molded parts even for complicated designs.

Prolean Tech lets you easily upload your part design once you have registered with them. As much more than a quote, a response is received upon submission. Incoming feedback and consultant advice on DFM guarantees that a project will go smoothly from prototyping to full production. Get in contact with our team now and receive the highest-quality injection molding service available!

Key Takeaway

When comparing injection molding vs vacuum forming, plastic injection molding advantages are more. Each process has its pros and cons, making it possible to achieve different levels of production. Selecting plastic injection molding means getting standard in quality, quantity, and rate. It makes a good bet for anyone who wants to embark on the production of quality products using efficient processes that do not make the final products very expensive as a unit compared to vacuum-forming.

0 Comments