Horizontal vs vertical milling machine

The primary difference between horizontal and vertical milling machines lies in the orientation of the spindle. Horizontal mills feature a spindle that is parallel to the worktable, making it ideal for removing material from large, heavier parts. Vertical mills feature a perpendicular spindle that offers precision and greater flexibility for detailed design cutting.

However, this simple difference may not completely define horizontal vs vertical milling center, and both machines are capable of milling. Both setups excel in milling applications, and at Proleantech, we use both machine types to ensure custom milling with higher efficiency and cost-effective manufacturing needs.

What are Milling Machines Used For?

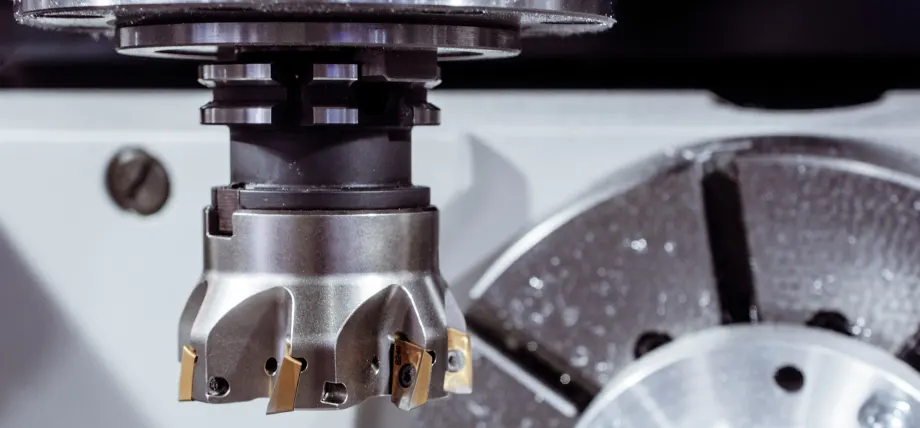

Milling machine cutter

Milling machines use high-speed spinning cutter tools to remove material during machining. A mill is defined by its rotating cutting tool, often with multiple teeth. These milling machines can shape metals, plastics, and fiber composites by adjusting cutting speeds and feed rates, changing tool ends, and other machining parameters.

A milling machine shapes a workpiece through operations like face milling, end milling, drilling, boring, and slotting. Computer numerical control (CNC) milling machines expand these capabilities to contouring, pocketing, and advanced material removal techniques at much faster speeds.

Machine shops use milling machines for prototyping, creating fixtures, and operations like cutting. Manual or CNC milling setups are used for:

- Face milling, slotting, drilling, and contouring

- Producing flat surfaces, pockets, and complex geometries

- Machining parts for aerospace, automotive, and industrial applications

Horizontal Mill Explained

Horizontal CNC Milling Machine with the Controller Panel

A horizontal milling machine features a spindle oriented parallel to the worktable. You can tell a horizontal mill from the position of the cutting tool as it laterally engages the workpiece. The spindle is mounted on an arbor that supports heavy-duty tools like slab mills.

Heavier tools, like side cutters, can also be mounted, which are ideal for removing large material volumes. The table moves along axes X and Y and the spindle adjusts along the Z axis. Horizontal mills are perfect for deeper cuts and higher material removal rates, and are generally used for large castings and forged parts.

One reason horizontal mills have a parallel spindle orientation is to aid chip evacuation for large parts.

Key Features of Horizontal Mills:

- Horizontal spindle with arbor support

- Suitable for deeper cuts and bulk machining

- Ideal for machining large workpieces

- Common in horizontal machining centers with multi-axis capabilities

Vertical Mill Explained

Vertical Milling Machine Center

A vertical milling machine uses a spindle perpendicular to the worktable. This orientation directs the cutting tool downward onto the workpiece, and it is ideal for precision milling operations like end milling, drilling, and contouring.

The spindle holds different milling tools, like end mills and drill bits. In a vertical mill, the worktable moves along the X, Y, and Z axes to accurately position the material removal from the workpiece. Some variants of the vertical mill include knee mills with an adjustable knee for table height and bed mills with a fixed base for stability. Turret milling machines feature a rotating turret for rapid tool changes.

Key Features of Vertical Mills:

- Vertical spindle orientation for precise cutting operations

- Compatible with end mills, ball mills, and other cutting tools

- Available in turret mills and bed mills configurations

- Direct tool mounting

- Integrated coolant and air systems for improved chip evacuation

Read More: 3 Axis vs 4 Axis vs 5 Axis CNC milling

10 Differences Between Horizontal Vs Vertical Mills

The spindle orientation difference and the resulting bed movement and chip removal system impact their application in machining processes. You can find 10 key differences between mill vs lathe:

1. Spindle Orientation

Spindle of a vertical milling machine with a cutting tool attached

Horizontal milling machines have a spindle axis parallel to the worktable, allowing them to cut side-entry workpieces. Horizontal mills can have multiple cutters that can engage the workpiece at the same time. Vertical milling machines feature a perpendicular spindle that directs the tool downward and perform a top-entry cutting on workpieces. The vertical spindle axis improves precision compared to the horizontal mill, but the horizontal mill’s spindle supports a wider surface engagement.

2. Cutting Tools

Horizontal mills have heavy-duty arbor-supported tools, like side and face cutters and slab mills designed specifically for heavy-duty material removal. These tools, typically 50-100 mm in diameter, can accommodate higher torque.

Vertical mills use longer, slender tools like end mills (5-25 mm) diameter and ball nose cutters. Tool geometry affects chip removal and deflection, and vertical tools are more prone to bending with higher torques and heavier loads.

3. Material Removal Rate

Horizontal mills have a higher material removal rate compared to vertical mills. A typical value for horizontal mills, MMR often exceeds 500 cm³/min. These mills can cut up to 10 mm per pass.

Vertical mills have MRRs typically below 300 cm³/min for steel as they prioritize precision and geometry with shallower cuts (1-5mm) to maintain accuracy.

4. Chip Removal

Metal chips from CNC cutting

Horizontal mills have the advantage of gravity to remove chips and avoid clutter. Chips falling downward minimize the risks of recutting and tool wear. Vertical mills require coolant flow to clear chips, and if the chips are not removed, they can accumulate, causing surface defects.

5. Cutting Depth

Horizontal mills can perform deeper cuts with greater rigidity because of their heavy-duty arbor support. Vertical mills are limited in cutting depth due to spindle deflection and the length of the cutting tool.

6. Set up Difference Between Horizontal and Vertical Mills

Clamping vice for a custom part

Vertical mills have a simpler setup due to their direct spindle visibility and access. Vertical mills reduce alignment time, zeroing time to a few minutes for most parts. Horizontal mills require arbor installation and overarm bracing, increasing setup time for even the most skilled machinists. If there is a multi-cutter configuration, the setup times can increase further. CNC programming for horizontals often involves toolpath consideration, specifically for arbor alignment.

Try Prolean Now!

7. Cost and Maintenance of Milling Machines

Vertical milling machines with multiple tool setups have lower initial costs and cost upwards of $10,000. Vertical mills are more accessible for small machine shops. Horizontal mills with strong machine beds and strong structures often start at $50,000 and involve higher maintenance costs due to the arbor, bearing, and loads involved.

8. Floor Space and Machine Footprint

Vertical milling machines, including turret and bed mills, have compact footprints of about 2 – 3 m2. Horizontal mills, with extended arbor, can take up a significant amount of space, often above 5 m2, making it difficult to operate horizontal mills in confined machine shops.

9. Spindle Speed Range and Control

Horizontal mills typically operate at lower spindle speeds compared to vertical mills. This is because horizontal mills use heavy-duty cutting tools that can cut deeper and remove more material in a single pass. Vertical mills have wider spindle speeds, often up to 20,000 RPM or more, for high-speed milling and finer surface finishes on metals. The spindle speed affects cutting parameter optimization in vertical and horizontal setups.

10. Workpiece Clamping

Horizontal mills have a stronger, heavy-duty clamping system to secure larger workpieces against sideways (lateral) cutting forces. Depending on the part complexity, horizontal mills use custom fixtures.

Vertical mills use simpler vices that fix the workpiece and work with smaller workpieces, with most milling machines handling up to 500 Kg. They face challenges in part fixing if lateral cutting forces are involved or when the otool comes from the side. For this reason, often the workpiece is re-oriented to machine different faces of the workpiece.

Try Prolean Now!

Choosing Between Horizontal or Vertical Mill for Your Metal Parts

Selecting between horizontal milling and vertical milling depends on part geometry, material, and the size of the part. Horizontal milling machines excel at quick sizing down and material removal in high-volume roughing for large components like steel housing, with higher material removal rates to reduce cycle times.

Materials can also affect your milling machine choice; horizontal mills handle ferrous metals, and for materials like steels and aluminum, where a surface finish is required, it is better to use a vertical milling machine and high speeds.

When selecting a milling machine, consider:

- Part geometry and size

- Required material removal rate

- Available floor space

- Tooling complexity

Try Prolean Now!

Conclusion

Understanding the key differences between horizontal vs vertical milling machines is important for machining parts and optimizing toolpaths. Each configuration has its advantages based on cutting tools, spindle orientation, and material removal rate. Whether you choose horizontal or vertical mills, you must match machining capabilities with project demands to ensure efficiency in part manufacturing.

Custom CNC Milling Solutions

Are you looking for custom CNC milling and machining for metals, plastics and composites? Proleantech offers high-quality, ISO certified parts for your project with 5-axis and Swiss milling solutions.

Contact us today for a free quote and lead times of less than 72 hours.

FAQ

How Is a Horizontal Milling Machine Different From a Vertical Milling Machine?

A horizontal milling machine uses a spindle axis parallel to the table. This supports multiple cutters on an arbor for heavy-duty machining. A vertical milling machine has a vertical spindle, ideal for precision and smooth surface finish milling.

What do you think Lather or Mill for My 10cm x 10cm Aluminum prototype?

I think lather is more cost-effective for the size you mentioned, only design does not have complex geometry