Laser cutting guide.

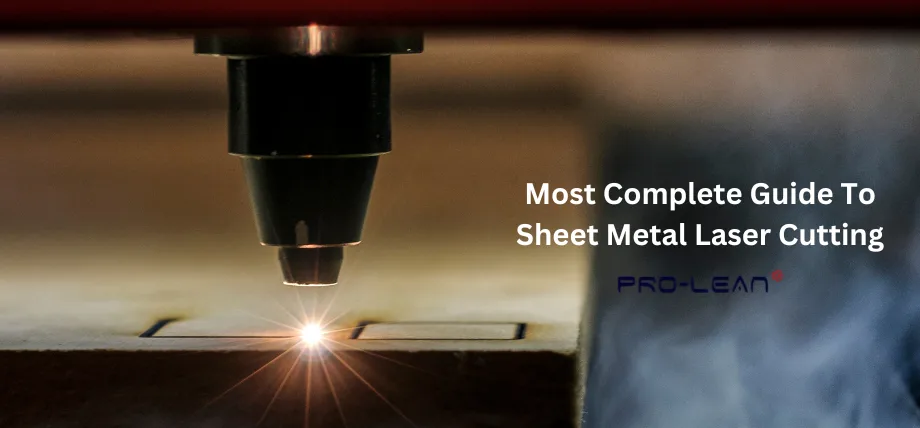

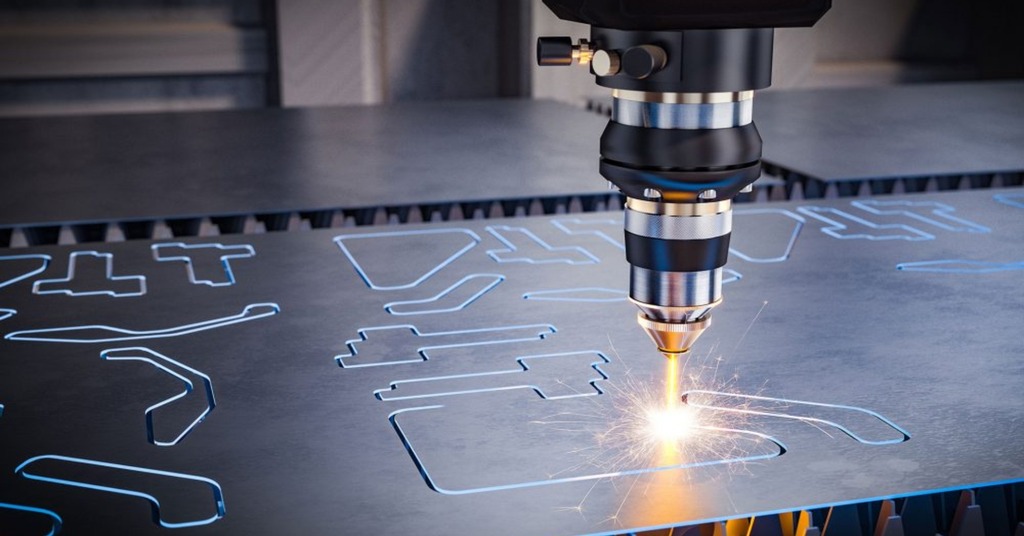

The manufacturing process of sheet metal cutting uses high-energy laser beams to make precise cuts in metal sheets, which enables the creation of complex components. The metal surface receives a focused light beam, which produces intense energy that leads to melting, vaporization, and burning at the focal point.

The metal cutting process relies on fiber lasers and CO2 lasers, but fiber lasers perform better because they match the wavelength requirements. The process produces precise cuts with narrow kerf widths, which makes sheet metal laser cutting suitable for manufacturing operations that need exact dimensions.

Sheet metal laser cutting technology at Proleantech enables engineers to process materials ranging from thin gauges to thick materials at high speeds. Proleantech laser cutting service provides extremely precise cuts with minimal heat damage to create superior part quality and clean edges. The combination of CNC control with laser systems yields repeatable results, enabling affordable production with fast delivery times.

What Is Laser Cutting of sheet metal?

The process of laser cutting metal sheets involves precisely aiming a laser beam at a metal sheet to induce thermal separation. The laser produces a highly focused beam of coherent light, which passes through a resonator system including fiber or gas tubes before passing through optical components to create a precise focal point.

The concentrated beam heats the material until it reaches its melting or vaporization point, which enables the cutting operation. The metal surface interacts with the beam during sheet metal laser cutting, which removes material according to programmed paths to produce specific shapes.

Thickness Range and Types of Laser Cutting?

Intricate laser cuts.

The thickness range of materials that sheet metal cutting methods like laser cutting can handle depends on the material type, the laser power, and the system configuration. The cutting process of metal materials benefits from fiber lasers due to their high efficiency; however, CO2 lasers perform better in specific applications, particularly for cutting thick metals.

The table below displays the maximum cutting thickness for various metals including laser cutting titanium when utilizing standard power levels of 2-6 kW for fiber lasers and 1-4 kW for CO2 lasers.

|

Material |

Fiber Laser Max Thickness (mm) |

CO2 Laser Max Thickness (mm) |

Notes |

|

Mild Steel |

25-50 |

10-20 |

Higher power enables thicker cuts; oxygen assist enhances speed. |

|

Stainless Steel |

20-40 |

8-15 |

Stainless steel laser cutting uses nitrogen gas to prevent oxidation for clean cuts. |

|

Aluminum |

15-30 |

5-10 |

Laser cutting aluminum requires higher energy in CO2 systems to prevent oxidation. |

|

Copper |

10-20 |

3-8 |

Copper laser cutting benefits from Fiber lasers, which handle reflectivity better. |

|

Brass |

10-25 |

4-10 |

Similar to copper, solid-state lasers provide precise control. |

What Is the Laser Cutting Process of Sheet Metal?

Step 1: Design and Programming

The design process starts with engineers who use CAD software to create 2D or 3D models that include precise dimensions and tolerances and optimized material arrangements for maximum efficiency. The design information gets converted into G-code through CAM software, which defines the cutting route and specifies laser power levels, speed, and assist gas operation parameters.

The programming process needs to be precise because it helps reduce mistakes and enables the creation of intricate designs.

Step 2: Material Preparation and Setup

Metal sheets on bed.

The metal sheet undergoes flatness inspection followed by cleaning operations to eliminate surface oils, which could interfere with beam absorption. The machine bed receives the metal sheet, after which it gets fastened by clamps or magnetic fixtures to stop any movement. The laser head needs precise positioning verification through sensors to ensure correct alignment with the metal sheet.

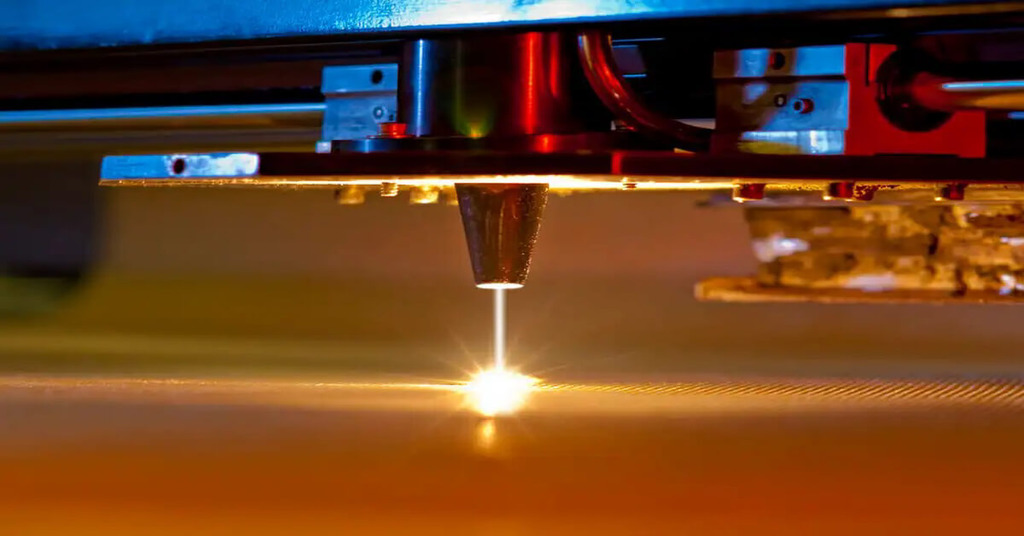

Step 3: Laser Beam Generation and Focusing

The fiber laser source activates to generate a coherent beam, which operates as the primary laser source for metal processing. The fiber system produces light at 1.07 μm wavelength through diode-pumped ytterbium operation.

The beam travels through mirrors or fiber optics before reaching the cutting head, where lenses concentrate it into a spot size of 0.1-0.5 mm, producing power densities exceeding 10^8 W/cm².

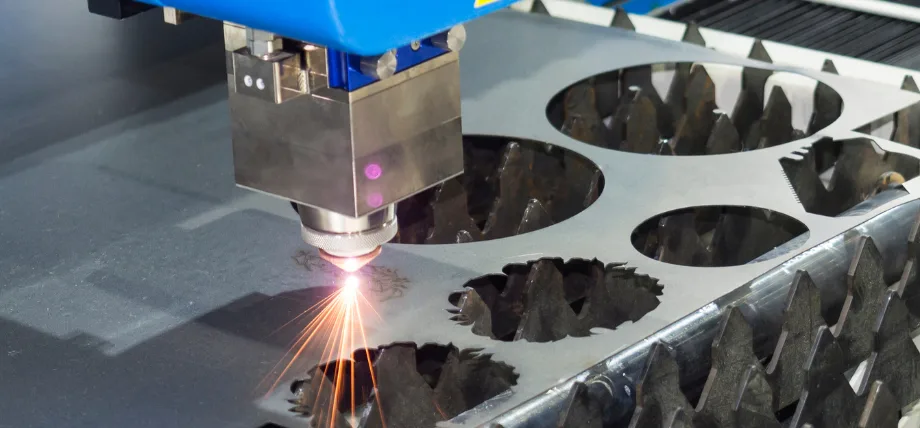

Step 4: Initiation of Cutting

Laser cutting metal.

The laser starts piercing at the beginning point through repeated pulses, which form an initial hole. The cutting nozzle directs assist gas at a pressure of 5-20 bar to remove debris while maintaining area cooling. The exothermic reaction between oxygen and mild steel during reactive cutting operations boosts cutting speed by 30-50%.

Step 5: Material Removal and Path Following

The CNC-operated laser head moves across the sheet while its powerful beam heats the metal material through melting and vaporization. The cutting speed of a 4 kW fiber laser system reaches 2-3 m/min when processing 10 mm stainless steel sheets at different power levels. The process produces a precise kerf width of between 0.15 and 0.5 mm during operation.

Step 6: Gas Assistance and Debris Management

The process uses nitrogen gas for fusion cutting of brass and copper to prevent dross formation, while oxygen gas speeds up the cutting of mild steel. The gas stream removes molten material from the cutting area, which results in a clean cut and reduces the heat-affected zone to 0.1-1 mm.

Step 7: Monitoring and Adjustment

The system includes real-time sensors that track beam quality and focus, as well as cut integrity performance. The system uses adaptive control to modify operational parameters automatically when material thickness or type changes, which results in better overall performance.

Step 8: Completion and Inspection

The laser turns off after completing the path, and operators retrieve the finished parts. The inspection process utilizes calipers and CMM to verify dimensions against specifications, making necessary parameter adjustments for future production runs to address any detected issues.

The detailed laser cutting of metal sheets process delivers superior results, which make it the preferred choice for complex applications.

Try Prolean Now!

What Metals a Laser Beam Can Precisely Cut?

What is Laser Cutting? It is a versatile process that can be used to cut a wide range of metals with varying thicknesses. Some of the metals commonly cut using laser cutting technology include:

1. Steel

Laser cutting is highly effective for cutting various types of steel, including carbon steel, stainless steel, and alloy steel. It can produce precise cuts in thin to thick steel sheets. Laser cutting is particularly well-suited for cutting stainless steel due to its ability to produce clean, high-quality cuts with minimal heat-affected zones. Stainless steel is commonly used in industries such as food processing, medical devices, and automotive manufacturing, where precision and hygiene are paramount.

2. Aluminum

Aluminum is another popular metal for laser cutting due to its lightweight, corrosion resistance, and versatility. Laser cutting can be used to cut aluminum sheets of different thicknesses, making it suitable for applications such as aerospace components, signage, and architectural elements.

3. Copper

While copper has traditionally been challenging to cut using laser technology due to its high reflectivity and thermal conductivity, advances in laser technology have made it possible to cut copper with precision and efficiency. Laser cutting is commonly used for fabricating copper components in electronics, telecommunications, and electrical industries.

4. Brass

Laser cutting is also suitable for cutting brass, a popular alloy of copper and zinc known for its attractive appearance and corrosion resistance. Brass is commonly used in architectural applications, decorative elements, and musical instruments, where intricate designs and precise cuts are desired.

5. Nickel Alloys

Laser cutting is capable of cutting nickel alloys, such as Inconel and Monel, which are known for their high temperature and corrosion resistance. These alloys are commonly used in aerospace, chemical processing, and marine applications, where they require precise machining and fabrication.

What Materials Cannot Be Cut by a Laser Cutting Machine

Copper sheets stacked.

- Polyvinyl Chloride (PVC): The cutting of PVC produces chlorine gas and hydrochloric acid, which can damage equipment parts and pose a risk to human health.

- Polycarbonate: The material absorbs excessive infrared radiation, which causes it to melt and char before potentially igniting when cut without proper techniques.

- ABS Plastic: The process of cutting ABS Plastic produces cyanide fumes, which create toxic conditions for operators in the workplace.

- High-Density Polyethylene (HDPE): The material of High-Density Polyethylene (HDPE) produces excessive melting that creates unclean residues and results in poor cutting edges.

- Carbon Fiber Composites: The high thermal conductivity of carbon fiber composites can lead to uneven heating, which can damage the material’s structure.

- Ceramics and Thick Glasses: The insufficient energy absorption of ceramics and thick glasses results in material cracking instead of controlled cutting processes.

- Highly Reflective Metals like Pure Copper (for CO2 lasers): Pure Copper and other highly reflective metals act as beam reflectors, which decreases system performance and endangers optical components, but fiber lasers provide better performance against extreme conditions.

Materials with Formaldehyde (e.g., some MDF): The combination of formaldehyde in materials such as MDF can result in hazardous chemical releases and irregular cutting results due to variations in material density.

Types of Lasers for Sheet Metal Laser Cutting

When it comes to laser cutting sheet metal, most manufacturers prefer CO2, Crystal, and Fiber Lasers due to their advanced cutting features. Let’s discuss each type in detail;

1- CO2 Lasers

Carbon Dioxide (CO2) Lasers operate via electrical discharge through a gas mixture containing carbon dioxide, nitrogen, hydrogen, and helium. They produce visible light in the far-infrared region of the electromagnetic spectrum.

CO2 Laser

Furthermore, CO₂ lasers are suited for cutting non-metallic materials like wood, paper, polymethylmethacrylate (PMMA), and other acrylic plastics. Additionally, they can process thin sheets of aluminum and non-ferrous metals.

In addition to their versatility, high-powered CO2 lasers can handle thicker metals, reaching up to several centimeters. However, they are less suitable for highly reflective metals, such as brass and copper, though newer CO2 lasers with enhanced oxygen content can somewhat overcome this limitation.

2- Fiber Lasers

Fiber lasers utilize optical fibers filled with dopants (such as neodymium) to amplify light. They offer excellent beam quality and high intensity, allowing for faster cutting rates and smaller kerf widths.

Fiber Laser

Moreover, fiber lasers are ideal for cutting various materials, including metals, non-metals, and alloys. Even though they can handle thin metals but are least efficient for thicker materials beyond approximately 20 millimeters.

Additionally, more expensive models can cut up to 6 kilowatts, enabling them to handle thicker materials. Their superior performance in these conditions makes them excel in cutting highly reflective metals, such as brass and copper. Besides cutting, they are ideal for other operations like annealing and laser engraving.

3- Crystal Lasers

Crystal lasers, also known as solid-state lasers. The most common crystal materials used in crystal lasers include; neodymium-doped yttrium aluminum garnet (Nd: YAG), neodymium-doped yttrium lithium fluoride (Nd: YLF), and erbium-doped yttrium aluminum garnet (Er: YAG). These Lasers utilize crystals to create beams.

They provide high output power and energy efficiency, making them suitable for cutting, welding, and engraving materials such as metals, ceramics, and plastics. Additionally, crystal lasers can operate at different wavelengths, allowing for precise control over the laser beam’s characteristics and absorption properties in the material being processed.

Furthermore, crystal lasers are compact, reliable, and have a long lifespan, making them a popular choice for industrial and scientific applications where stability and performance are crucial.

Best Laser Cutting Machine for Laser Cutting Sheet Metal

STYLECNC ST-FC3015FM

StyleCNC ST-FC3015L cutter.

The STYLECNC ST-FC3015FM stands as the top sheet metal laser cutter due to its 5×10 ft bed size and power levels ranging from 1.5 kW to 20 kW. The machine achieves maximum cutting speeds of 140 m/min while processing mild steel up to 50 mm thick, stainless steel up to 40 mm thick, and aluminum up to 30 mm thick. The fiber laser technology of this machine delivers both high energy efficiency and precise control, which makes it suitable for large-scale manufacturing operations.

Trumpf TruLaser Series

Trumpf TruLaser 3530.

The TruLaser models from Trumpf use solid-state lasers to achieve exceptional precision during metal cutting operations. The machines operate at maximum power levels of 24 kW to process brass and copper materials effectively while producing minimal heat-affected zones. The machines feature automatic nozzle changers, along with AI-based parameter optimization systems, which reduce production time and yield better part quality.

OMTech Fiber Lasers

Omtech FC-105 machine.

OMTech offers budget-friendly fiber laser systems for sheet metal applications, capable of reaching maximum power levels of 12 kW. The machines deliver fast cutting speeds while producing clean edges when processing stainless steel up to 30 mm thick and mild steel up to 40 mm thick. These machines are top choices for small to medium-sized businesses that want affordable operations with high performance.

Techniques for Laser Cutting Sheet Metal

Several techniques are employed for laser cutting sheet metal, each offering unique advantages and applications. Some of the most common techniques include:

Sheet Metal Laser Cutting

1. Laser Beam Fusion Cutting

In this process, the laser beam heats the material to its melting point, and a high-pressure gas, typically oxygen or nitrogen, blows away the molten material to create the cut.

Fusion cutting is versatile and suitable for a wide range of metals, including steel, aluminum, and stainless steel. Moreover, its ability to cut complex shapes and intricate patterns with ease makes it suitable for various industrial applications.

2. Laser Beam Flame Cutting

Flame cutting, also known as reactive cutting, is a variation of fusion cutting used for thick sheet metal. It is most suitable for cutting carbon steel, stainless steel, and aluminum among other metals. In this technique, oxygen is used as the assist gas, and the laser beam reacts with the metal to create an exothermic reaction, producing intense heat that melts the material.

3. Laser Beam Sublimation Cutting

Sublimation cutting is a process used primarily for cutting thermally sensitive materials, such as certain plastics and polymers. In sublimation cutting, the laser beam heats the material directly to its vaporization point, bypassing the liquid phase. Therefore, it results in clean, precise cuts with minimal heat-affected zones and is suitable for materials that are sensitive to melting or burning.

Try Prolean Now!

Laser Cutting Services

At Proleantech, we differentiate from other laser cutting services by optimizing your laser cutting toolpaths and engineering products to produce burr free edges in parts, producing parts with minimal heat-affected zones, and using the best laser cutting machines.

Custom metal laser cutting is ideal for most materials and metal plates. It offers the benefit of a non-contact cutting process that requires no physical tooling.

Get the shortest lead times for your laser cutting needs by simply requesting a free quote.

Conclusion

The advanced laser systems in sheet metal laser cutting produce precise and efficient metal processing that outperforms flame cutting and other methods by delivering faster results with superior quality.

The system achieves high-quality part production through its power and speed control functions, which are compatible with various materials, including mild steel, stainless steel, aluminum, copper, and brass. The technology offers three main benefits through its minimal heat-affected zones and super clean cuts, as well as its ability to process a wide range of thicknesses, making it essential for manufacturing operations.

FAQ

Can you laser cut sheet metal?

Sheet metal cutting through laser technology proves highly effective because it uses a concentrated beam to produce clean cuts in materials such as mild steel and aluminum. The precision and speed of fiber lasers make them ideal for processing a wide range of metal thicknesses.

How thick can laser-cut sheet metal be?

High-power fiber lasers enable sheet metal cutting up to 50 mm in thickness for mild steel, 40 mm for stainless steel, and 30 mm for aluminum. The maximum cutting thickness depends on laser power output, material type, and machine operational limits.

How accurate is laser cutting titanium sheet?

The precision of laser cutting titanium sheet reaches ±0.05 mm to ±0.2 mm accuracy, with kerf widths reaching 0.1 mm. The precision of fiber lasers reaches its peak due to cutting speed and beam focus settings.

Which material should you never cut in the laser cutter?

The laser cutter should never process PVC because it produces toxic chlorine gas and acidic substances, which harm equipment and endanger operator health. The laser cutter should not process polycarbonate or ABS plastics because they produce dangerous chemicals that damage equipment and harm operators.

0 Comments