“Vacuum casting is more than just forming objects; it’s about changing how we think about accuracy, speed, and making custom parts. This technique is a big part of China’s industrial strength, pushing the manufacturing boundaries.”

Vacuum casting is a versatile manufacturing process renowned for creating precise and high-quality replicas, especially rapid prototypes and Short-batch production. However, high mold cost makes the prototyping expensive. Vacuum Casting services in China could be cost-effective, yet precise for you. Its ability to replicate fine details and textures makes it invaluable across diverse sectors from all over the world. As we discuss further vacuum casting, we’ll explore the nuances of China vacuum casting services, their capabilities, benefits, applications, how to outsource, Cost, and more.

What is Vacuum Casting?

Vacuum casting is renowned for its precision, it allows for the creation of high-quality replicas, leveraging a vacuum to draw liquid materials into a mold, perfectly capturing intricate details and textures.

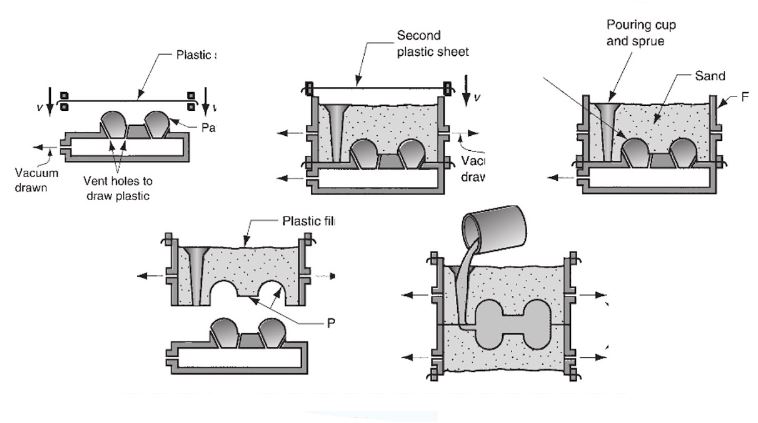

The Process of Vacuum Casting

In vacuum casting, a meticulous process is followed to ensure each replica is as close to the original design as possible. Starting with a master model, typically created through advanced methods such as 3D printing, the process involves several key steps:

- Master Model Creation: The process begins with the creation of a detailed master model, often utilizing 3D printing or CNC machining for high accuracy.

- Silicone Mold Formation: This master model is then used to create a silicone mold, capturing every nuance of the design.

- Resin Pouring and Vacuum Application: A liquid resin is poured into the mold, and a vacuum is applied, ensuring the resin fills every part of the mold evenly.

- Curing and Demolding: The resin is allowed to cure, solidifying into a precise replica, which is then removed from the mold.

Vacuum casting process

Vacuum casting finds extensive application in various sectors. In the automotive industry, complex parts are prototypes. In the medical field, it produces detailed components for medical devices. The entertainment industry benefits from vacuum casting for the creation of realistic and intricate props and models.

Click here to download: The Comprehensive Overview of Vacuum Casting

Try Prolean Now!

Master Model and Silicone Mold in Vacuum Casting Services

In vacuum casting service, creating a master model and a silicone mold are crucial steps in determining the final product’s success and quality. These components play a pivotal role in the process, serving as the foundation upon which replicas are formed.

What is the Master Model?

The master model is the original prototype of the silicone mold. This model precisely represents the final product and is typically created using high-precision techniques such as 3D printing or CNC machining. The accuracy and quality of the master model are essential, as any flaws or errors will be replicated in the silicone mold and, subsequently, in every cast part.

3D modeling for vacuum casting

The process begins with a detailed design, usually developed using CAD and CAM software. This design is then translated into a physical model. The model is produced using 3D printing or CNC machining. 3D printing is often preferred for its ability to produce complex geometries with high precision. After production, the model undergoes finishing processes, including sanding and painting, to achieve the desired surface quality and appearance.

What is Silicone Mold?

After the master model is created, it is used to form a silicone mold, which is essentially a negative of the master model. Silicone is chosen for its flexibility, heat resistance, and ability to capture fine details. The mold can produce multiple copies of the master model, making it a cost-effective solution for small to medium production runs.

![]()

Silicone mold and part

Creating the Silicone Mold

- Preparation of the Master Model: The master model is placed in a container and positioned to ensure the mold captures all details.

- Pouring Silicone: Liquid silicone is mixed and poured over the master model. The silicone then cures around the model, forming a mold.

- Curing and Mold Removal: The silicone is allowed to cure and harden. Once cured, the mold is carefully cut open and the master model is removed, leaving a hollow cavity in the shape of the model.

- Mold Finishing: The silicone mold might require minor finishing to ensure it’s ready for the casting process.

Related: Comprehensive Guide to Silicone Rubber Moldings

Vacuum Casting Services China Capabilities

Vacuum casting services in China stand out for their exceptional technical precision, cost-effectiveness, skilled workforce, and robust supply chain, catering to diverse global manufacturing needs.

Technical Capabilities

The technical prowess of vacuum casting services in China is unparalleled, primarily due to cutting-edge technologies, such as CNC-AI integration, and adherence to stringent quality standards. This technological edge allows for;

- High Precision and Detail: Advanced machinery and tools ensure that every replica or prototype is accurately produced, capturing even the most intricate details.

- Material Versatility: Chinese vacuum casting services can work with a diverse array of materials, from standard resins to specialized polymers, adapting to the specific needs of different industries.

- Large Scale and Custom Production: These services are not limited to small-scale production but are also capable of handling large orders, providing flexibility for both prototyping and mass production.

Precise vacuum casted part

The technical capabilities extend beyond machinery and materials. The process management, from design to final production, is streamlined for efficiency and precision, ensuring that every project, regardless of its complexity, is executed excellently.

have a track record of similar projects before.

Try Prolean Now!

Economical Capabilities

One of the most significant advantages of vacuum casting services in China is their cost-effectiveness. Combining advanced technology and efficient production methods results in a cost-saving approach that does not compromise on quality. Key aspects include:

- Cost-Effective Production: The efficient use of materials and energy, along with optimized labor costs, makes vacuum casting in China highly economical, particularly for bulk orders.

- Reduced Waste and Energy Usage: Chinese vacuum casting processes are designed to minimize waste and energy consumption, contributing to lower production costs and a smaller environmental footprint.

- Competitive Pricing: Due to the high volume and efficient operations, Chinese firms can offer competitive pricing, making them an attractive option for businesses looking to maximize their budget without sacrificing quality.

These economical capabilities make China a go-to destination for companies seeking high-quality vacuum casting services at a reasonable price, providing an excellent balance between cost and performance.

Expert Engineers and Operators

The workforce behind China’s vacuum casting services is a blend of experienced engineers and skilled operators. This human resource factor plays a crucial role in maintaining high production standards. Highlights include:

- Highly Trained Professionals: Engineers and operators in Chinese vacuum casting facilities are well-trained, often with specialized education and extensive experience in the field.

- Continuous Skill Development: There is a strong emphasis on ongoing training and skill enhancement, ensuring that the workforce stays abreast of the latest technologies and industry practices.

- Problem-Solving and Innovation: The combination of technical know-how and practical experience allows Chinese professionals to tackle complex projects with innovative solutions, enhancing overall efficiency and product quality.

This pool of talent is fundamental in driving the success and reliability of vacuum casting services in China, ensuring that every client’s needs are met with expertise and professionalism.

Excellent Supply Chain

China’s robust supply chain infrastructure significantly enhances the capabilities of its vacuum casting services. This includes:

- Reliable Material Sourcing: Access to a wide range of high-quality materials at competitive prices is assured, thanks to China’s extensive network of suppliers.

- Swift and Efficient Logistics: With a well-developed transportation network, vacuum casting products can be quickly and efficiently shipped to destinations worldwide.

- Streamlined Production and Delivery: The integration of supply chain management with production processes ensures timely delivery of products, reducing lead times and enhancing customer satisfaction.

The supply chain competence not only supports the operational efficiency of vacuum casting services in China but also adds to their global appeal by ensuring reliability and timeliness in every project.

Material Versatility

You can process any compatible material with Chinese vacuum casting services, from transparent to metallic resin for diverse industry needs. The following are some vacuum casting materials, commonly available at every China vacuum casting firm.

- Polyurethane Resin

- ABS-like Resin

- Polypropylene-like Resin

- Transparent Resin

- High-impact resin

- High-temperature resistant Resin

- Flexible Rubber-like Resin

- Silicon Rubber

- Epoxy Resin

- Polycarbonate-like Resin

- Glass-filled nylon

- Soft-Touch Materials

- Flame Retardant Resin

- Water Clear Resin

- Metallic-Filled Resins

These different material processing capabilities can address your needs in any industry. However, there need to consider several factors during vacuum casting according to the properties of the material. The Chinese Vacuum-casting industry brings all the expertise to analyze material science with casting technology. So, choose a firm that is experienced in the industry and

Try Prolean Now!

China Vacuum Casting Services Cost

The cost is a critical consideration for businesses seeking high-quality manufacturing solutions. Known for its cost-effectiveness, China has become a global hub for vacuum casting, offering competitive pricing without compromising quality. Several factors, including economical labor costs, efficient production processes, and a robust supply chain drive this affordability. The strategic location of manufacturing facilities also plays a role in minimizing transportation and logistics expenses.

Several elements influence the cost of vacuum casting services in China:

- Material Selection: The type of resin or other materials used can significantly impact the cost. For example, specialty materials tend to be more expensive.

- Mold Complexity: Intricate molds that require more time and precision to create can increase costs.

- Production Volume: Larger quantities typically reduce the cost per unit, benefiting bulk orders.

- Design Specifications: Complex designs requiring additional labor or special techniques can affect the price.

- Surface Finishing Requirements: Post-casting processes like painting, sanding, or special surface treatments add to the cost.

- Lead Time: Expedited orders may incur additional charges for faster turnaround times.

Considering these factors helps with vacuum casting project planning and budgeting, ensuring a balance of cost and desired quality.

Why China is Cost-effective for Vacuum Casting Services

China’s vacuum casting services offer several advantages that contribute to their cost-effectiveness:

- Economies of Scale: China’s large manufacturing infrastructure allows for the efficient production of large volumes, reducing the cost per unit.

- Advanced Technology and Automation: Investment in modern technologies and automation in manufacturing processes reduces labor costs and increases efficiency.

- Skilled yet Affordable Labor: The availability of a skilled workforce at relatively lower wages compared to Western countries helps keep costs down.

- Strong Supply Chain Network: An established network of material suppliers and logistics providers ensures competitive pricing and efficient delivery.

These factors combine to make China a preferred destination for vacuum casting services, offering a balance between affordability and quality.

Table: Cost Comparison of Vacuum Casting Services by Region

| Region/Country | Average Cost per Unit | Labor Cost | Material Cost | Overhead Costs |

| China | Low | Low | Moderate | Low |

| USA | High | High | High | High |

| Europe | Moderate | High | High | Moderate |

| India | Moderate | Low | Moderate | Moderate |

Note: The table provides a general comparison and may vary based on specific project details and current market conditions.

How to Outsource Vacuum Casting Services from China?

Outsourcing vacuum casting services from China requires careful planning and understanding of international trade dynamics, from selecting the right supplier to managing logistics and quality control.

Step 1: Identifying Suitable Suppliers

Start with thorough research to find reputable suppliers. Use online platforms and industry networks. Then, perform due diligence to assess their capabilities, quality standards, and track record. Next, visit or virtually assess their facilities if possible. Verifying their manufacturing capabilities is crucial and confirming they meet your project’s specific requirements.

Step 2: Evaluate the Technical Capabilities

Check if the supplier has the necessary modern facilities and equipment. Their ability to handle diverse materials and complex designs is crucial. Also, ensure they have robust quality assurance processes and relevant certifications to meet your standards.

Additionally, understand their production capacities to ensure they can handle your order volume. Discuss any potential challenges or limitations upfront to avoid future complications. This step solidifies your confidence in their ability to deliver.

Step 3: Discuss and Finalize the Project Details

Communicate your project specifications, including design, material needs, and quality expectations. A detailed discussion helps in aligning expectations and capabilities. Also, agree on a realistic production timeline and clear milestones.

Discussing costs is crucial. Understand their pricing structure and negotiate terms.

Step 4: Sample Production and Approval

Request a prototype or initial batch to assess quality. This step is crucial for ensuring the final product meets your expectations. Review the sample meticulously and provide detailed feedback for any adjustments. If it needs any modifications, request necessary changes or improvements. Only proceed to full production once you are completely satisfied with the sample.

Try Prolean Now!

Rapid Prototyping with China Vacuum Casting Services

Rapid prototyping is a crucial phase in product development, and vacuum casting services offer an efficient and cost-effective solution. It allows designers and engineers to quickly transform ideas into tangible, high-quality prototypes. The speed of vacuum casting is particularly beneficial in a fast-paced market, where getting a product from concept to prototype swiftly can be a significant competitive advantage.

Rapid prototyping with vacuum casting

The process begins with the creation of a master model, usually using 3D printing or CNC machining, which is then used to create a silicone mold. This mold can be used to produce multiple replicas in a range of materials, allowing for various iterations of the design to be tested and modified as needed. The flexibility in material selection means prototypes can closely mimic the properties of the final product, whether it be in terms of weight, texture, color, or strength.

Low-volume manufacturing with Vacuum Casting

Vacuum casting is not just for prototyping; it’s also an excellent choice for low-volume manufacturing. This method is ideal for producing small quantities of parts when the cost or time constraints of other manufacturing methods are prohibitive. Vacuum casting allows for the production of high-quality parts without the need for expensive tooling, making it a cost-effective solution for low-volume runs.

Table: Comparison of Vacuum Casting for Prototyping and Low-Volume Production

| Criteria | Rapid Prototyping | Low-Volume Manufacturing |

| Purpose | Quick development of prototypes for testing and design validation. | Efficient production of a limited number of parts for market testing or niche applications. |

| Volume | Typically less than 50 units. | Ranges from a few dozen to a few hundred units. |

| Cost | Lower due to no need for expensive tooling. | Economical for small runs compared to traditional manufacturing. |

| Materials | A wide range of materials is available to mimic final product properties. | Similar to prototyping, with an emphasis on durability for end-use. |

| Turnaround Time | Extremely fast, allowing for rapid iterations. | Slightly longer than prototyping but much faster than traditional methods. |

| Detail and Quality | High precision and quality, suitable for complex designs. | Equal to prototyping, ensuring high-fidelity parts. |

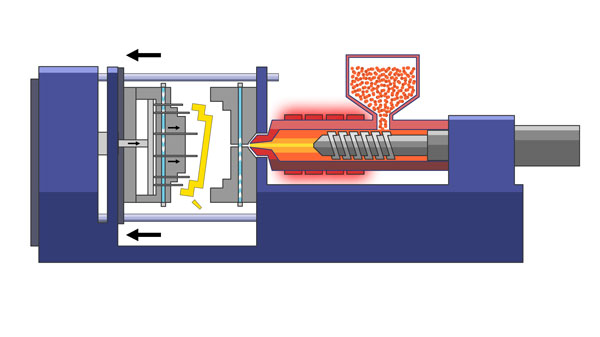

What Are the Differences between Vacuum Casting and Injection Molding?

Vacuum casting and plastic injection molding are both popular manufacturing techniques used for producing plastic parts and components, sharing similarities in their use for creating high-quality, detailed products from various plastic materials.

Injection molding process

However, they are significantly distinct in terms of their processes, scalability, and cost implications. Vacuum casting is ideal for smaller-scale productions, offering flexibility and lower mold costs, but with limited durability for the molds. On the other hand, injection molding is suited for high-volume production, characterized by its efficiency and the longevity of its metal molds, though with higher injection molding initial costs.

Table: Comparison of Vacuum Casting and Injection Molding

| Criteria | Vacuum Casting | Injection Molding |

| Process | Uses a vacuum to draw liquid resin into a silicone mold. | Involves injecting molten plastic material into a metal mold under high pressure. |

| Tooling Cost | Lower, as silicone molds are less expensive to produce. | Higher, due to the cost of creating metal molds. |

| Production Volume | Ideal for low to medium volumes is perfect for prototyping and small-batch production. | More suitable for high-volume production due to the durability of metal molds. |

| Lead Time | Shorter lead times due to a simpler mold-making process and faster setup. | Generally longer, as creating metal molds is more time-consuming. |

| Material Options | Offers a wide range of materials but is mostly limited to resins and similar polymers. | Supports a broader range of thermoplastic and thermosetting materials. |

| Part Complexity | Highly effective for complex geometries and intricate details, especially with undercuts. | Can handle complexity but may require more sophisticated mold designs, potentially increasing cost. |

| Surface Finish | High-quality surface finish with fine details. Post-processing may enhance appearance. | Excellent surface finish directly from the mold, often requiring less post-processing. |

| Flexibility | More flexible in terms of design changes; molds can be modified or remade at relatively low costs. | Less flexible once the mold is made; design changes can be expensive due to the need for new molds. |

| Precision and Consistency | Highly precise, but silicone molds can degrade over time, affecting consistency in longer runs. | Extremely consistent and precise, especially for large production runs, due to the stability of metal molds. |

How to Choose the Best China Vacuum Casting Service Provider?

Selecting the right vacuum casting service provider in China is crucial for the success of your manufacturing project. The perfect service partner ensures not only the quality and precision of the final products but also impacts the efficiency, cost, and overall experience. With numerous options available, it’s essential to carefully evaluate and choose a provider that aligns with your specific needs and quality standards.

The following are the key criteria to look for Best Vacuum Casting Service Provider.

- Evaluate Technical Expertise: Look for providers with advanced technical capabilities, modern equipment, and a track record of handling complex projects.

- Assess Material Versatility: Ensure they offer a wide range of materials and can advise on the best options for your project.

- Check Quality Control Processes: A reliable provider should have stringent quality control measures in place to ensure high-quality outputs.

- Consider Production Capacity: Determine if the provider can handle your volume requirements, whether it’s a small batch or large-scale production.

- Review Past Projects and Client Feedback: Examine their portfolio and seek reviews or testimonials from previous clients.

- Compare Pricing and Value: While cost is a factor, also consider the value offered in terms of service quality and additional offerings.

- Gauge Communication and Customer Service: Effective communication is key, especially when dealing with overseas suppliers. Prompt and clear communication indicates a good working relationship.

- Inquire About Lead Times and Delivery: Confirm their ability to meet your deadlines and their efficiency in logistics and delivery.

Related: Outsourcing the CNC Machining Service from China: Everything You Need to Know

Prolean Vacuum Casting Services for Rapid Prototyping and Short-batch Production

Prolean Vacuum Casting Service is a prime example of an ideal service provider that meets all the criteria for choosing the best in China. Prolean exemplifies excellence in every aspect of vacuum casting with advanced technology and a skilled team for tackling complex projects across various industries. Our diverse range of materials and commitment to quality position us at the forefront of the industry.

Prolean handles everything from prototypes to large-scale production. We balance competitive pricing with high-quality service, ensuring value for our clients. So, We are more than a service provider; we are a partner aligned with international standards and your expectations.

Read more:

- China Prototype Manufacturing: The Powerhouse of Rapid Prototyping

- CNC Milling Service in China: Comprehensive Insights

Summing Up

The Vaccum Casting offers a valuable approach for producing high-fidelity replicas, particularly beneficial for prototypes and small-batch production. While the process can be costly due to high mold expenses, alternatives like compression molding in China provide a cost-effective yet precise option. The versatility of vacuum casting in replicating fine details makes it invaluable across diverse sectors globally.

As we explore the nuances of China’s vacuum casting services, we explore its extensive applications, benefits, outsourcing strategies, costs, and more. Overall. the high level of detail, combined with the relatively low cost and quick turnaround times, makes vacuum casting services in China an attractive option for businesses looking for comprehensive solutions.

FAQs

What is Vacuum Casting?

Vacuum casting is a specialized manufacturing technique primarily used for prototyping and small-batch production, known for its precision and ability to create high-quality replicas.

How is a Master Model Created in Vacuum Casting?

The master model in vacuum casting is typically created using high-precision techniques like 3D printing or CNC machining, ensuring accuracy and quality in the final product.

What Materials Are Commonly Used in Vacuum Casting?

Materials commonly used in vacuum casting include polyurethane resin, ABS-like resin, transparent resin, and flexible rubber-like resin, among others.

What Industries Benefit from Vacuum Casting?

Industries like automotive, medical, entertainment, and aerospace benefit from vacuum casting for prototypes and detailed components.

How Does Vacuum Casting Compare to Injection Molding?

Vacuum casting is ideal for low to medium-volume production with flexible material options, while injection molding is better suited for high-volume production with consistent precision.

What Makes China a Leading Provider of Vacuum Casting Services?

China excels in vacuum casting due to its advanced technical capabilities, cost-effectiveness, skilled workforce, and robust supply chain, making it a go-to choice for global manufacturing needs.

0 Comments