“Did you know that the tightest tolerance in aerospace machining can be thinner than 1/10th the width of a human hair? Now, pause and consider: who ensures this precision? The answer is CNC milling.”

CNC milling for aerospace provides attention to detail and combines artistry with engineering. This fusion of precision and reliability with CNC milling brings unparalleled safety and innovation to the skies. The advanced CNC milling machines can craft several aerospace parts, from wing components to turbine blades. By the end of the article, you will get all insights into how CNC milling shapes various aerospace components, including international standards, applications, tips & tricks, and more.

Why is CNC Milling Critical for Aerospace?

The aerospace industry is known for its precision requirements and high-quality standards and continually seeks technological advancements to produce safer & efficient aircraft. CNC milling addresses all these requirements of aerospace manufacturing.

Let’s discuss in detail why CNC milling is critical for aerospace;

1. Precision and Tolerances

One of the fundamental reasons aerospace leans heavily on CNC milling is the exceptional precision it offers. Aerospace components require tight tolerances, often in the range of +/- 0.0001 inches. Such high precision ensures parts fit perfectly, ensuring optimal performance and safety.

Table: Common Tolerance Ranges in Aerospace CNC Milling. Source

| Part Type | Tolerance Range (in inches) |

|---|---|

| Engine Components | +/- 0.0001 to 0.0005 |

| Structural Components | +/- 0.001 to 0.005 |

| Instrumentation | +/- 0.0001 to 0.001 |

2. Adherence to Aerospace Standards

The aerospace sector operates under stringent standards set by bodies like the FAA or EASA. These standards encompass material use, design parameters, and production techniques. CNC milling, given its precision and consistency, ensures these standards are met, if not exceeded.

3. Material Versatility

The aerospace sector utilizes a diverse array of materials, from lightweight aluminum and titanium to robust superalloys. CNC milling machines, equipped with specific cutting tools, can seamlessly handle this material diversity.

4. Consistency in Mass Production

Aircraft manufacturing isn’t a one-off process. Instead, hundreds or even thousands of identical components are required. CNC milling ensures each piece is consistent with its predecessor, eliminating discrepancies that can compromise aircraft integrity.

5. Cost-Effective Manufacturing

While initial setup costs might be on the higher side, CNC milling proves cost-effective in the long run. It reduces wastage and optimizes the use of raw materials. With less manual intervention, the chances of human error, which can be expensive in terms of reworks and material waste, diminish considerably.

6. Intricate Designs

CAD Design of landing gear part

Modern aircraft designs incorporate complex parts, from the aerodynamically efficient wing components to detailed engine pieces. CNC milling, known for its ability to produce intricate designs, is perfect for these demanding tasks. By following a pre-programmed design file, the milling machine can carve out even the most complex geometries with ease.

7. Rapid Prototyping

Before mass-producing any component, aerospace engineers need prototypes to test design efficacy. CNC milling accelerates this prototyping phase. Engineers can quickly assess and modify designs, ensuring the final component is both efficient and safe.

Aerospace Machining/Milling Standards

Aircraft, whether they’re commercial jets, military fighters, or space shuttles, must be reliable, durable, and safe. A significant component of this reliability is ensured by the machining standards that dictate how aerospace parts are manufactured. Let’s dive into the critical aerospace machining and milling standards that set this industry apart.

1. International Quality Standards

Aerospace manufacturers across the globe adhere to several internationally recognized standards. One of the most prominent is the AS9100, an international reference for quality management specific to the aerospace sector. The AS9100 standard encompasses all ISO requirements and incorporates additional aerospace-related parameters, focusing on quality and safety. It ensures that all parts, regardless of where they’re made, meet consistent quality standards.

The following are the key machining standards for aerospace parts and systems.

Table: Overview of International Aerospace Quality Standards

| Standard | Purpose | Key Features |

|---|---|---|

| AS9100 | Quality Management in Manufacturing | Quality and safety focus |

| AS9110 | Maintenance and Repair | Emphasis on human factors, safety management |

| AS9120 | Stocking and Distribution | Chain of custody, traceability |

| NADCAP | Quality Assurance for Special Processes | Industry-driven, thorough audits |

| ISO 13485 | Medical Devices | Design and production consistency |

| EN 9100 | European Aerospace Quality | Product safety, risk management |

2. Material Standards

Different aerospace applications demand various materials, each having its own machining requirements.

Table: Common Aerospace Materials and their Milling Standards

| Material | Milling Consideration | Typical Use |

|---|---|---|

| Titanium | Slow cutting speeds, coolants required | Aircraft frames, jet engines |

| Aluminum Alloys | High-speed milling, sharp tooling | Aircraft body, wings |

| Nickel-based Super Alloys | Low-speed, high-pressure milling | Turbine blades |

3. Tolerance Standards

As discussed earlier, aerospace components require tight tolerances. But what do these tolerances look like? The aerospace components’ tolerances often range from +/- 0.0001 to 0.001 inches.

4. Inspection and Quality Assurance

Once parts are milled, they should undergo rigorous inspections with visual inspection, dimensional inspection, and no-destructive testing. These inspections are mandated by various aerospace standards to ensure every component is perfect.

First, every part is visually inspected for surface imperfections or obvious defects. Then, the dimensional inspection is required with advanced tools like a CMM machine. Finally, techniques such as ultrasonic testing or X-ray imaging must be employed to identify internal defects without damaging the part.

6. Certification and Documentation

Every aerospace component comes with its trail of documentation. These documents validate that the part was manufactured, inspected, and approved as per the stipulated standards.

- Material Certificates: These document the material source and its composition.

- Inspection Reports: Detailed reports showcasing inspection results, any deviations, and corrective actions taken.

- Process Flow Charts: These outline the entire manufacturing process, ensuring transparency and traceability.

Six Common Aerospace Parts Usually Created with CNC Milling

As we previously discussed, CNC milling is a go-to manufacturing technique for creating a variety of aerospace parts. Here are six common aerospace parts frequently crafted with CNC milling.

1. Turbine Blades

Aircraft turbine blade

Turbine blades are a crucial component of jet engines, directing airflow within the turbine. With their intricate design and the need for impeccable precision, CNC milling is often the chosen method for their production.

- Materials Used: Inconel, titanium, and stainless steel

- Significance: High precision ensures efficient fuel combustion and maximum thrust.

2. Landing Gear Components

The landing gear of any aircraft endures significant stress during take-offs and landings. CNC milling provides the accuracy and strength required for these components to be reliable.

- Materials Used: Titanium alloys, steel alloys

- Significance: Precision milling ensures the landing gear’s proper functionality and the safety of all aboard.

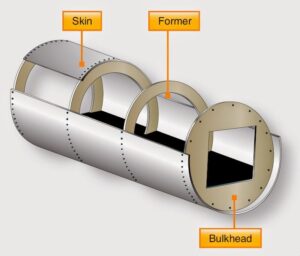

3. Aircraft Structural Components

Bulkhead structure in aircraft

Airframe parts, like ribs, spars, and bulkheads, form the aircraft’s skeletal structure. CNC milling offers the precision and consistency required for these parts, resulting in aircraft balance and stability.

| Component | Material | Function |

|---|---|---|

| Ribs | Aluminum | Provide shape to wings |

| Spars | Titanium | Support wing’s load |

| Bulkheads | Aluminum | Divide aircraft sections |

4. Satellite Components

Satellite part made with Beryllium milling

Satellites operate in the extreme conditions of space. Their components need to be exceptionally precise and resistant to temperature variations, which CNC milling can provide. Satellites like the Hubble Space Telescope contain precision-milled components that allow them to capture detailed images from space, millions of miles away.

- Materials Used: Aluminum, titanium, and certain plastics for non-structural parts

- Significance: Ensure long-lasting operation in space, resistant to cosmic radiation and temperature fluctuations.

5. Avionics Enclosures

Avionics refers to the electronic systems used on aircraft, artificial satellites, and spacecraft. Their enclosures protect these systems from external factors and interference.

- Materials Used: Aluminum, composites

- Significance: These enclosures shield avionics systems from electromagnetic interference, ensuring smooth communication and system operations.

6. Hydraulic Components

Hydraulic cylinder for aircraft created with CNC milling

Hydraulic systems control multiple flight-critical operations, from landing gear extension and retraction to wing flap adjustments. CNC milling is often used to craft the various components within these systems. The CNC-milled hydraulic components inside the aircraft ensure smooth fluid flow and withstand high pressures.

| Component | Material | Function |

|---|---|---|

| Valves | Stainless steel | Control fluid flow |

| Cylinders | Brass | Store hydraulic fluid |

| Pumps | Stainless steel | Circulate fluid |

Click here to download: CNC Milling for Aerospace-Complete Guide

Try Prolean Now!

Preparation of CNC Milling for Aerospace

Before initiating the CNC milling process for aerospace parts, it’s crucial to ensure that all necessary steps have been considered. Aerospace components require an extreme level of precision, given that they are subjected to high stress and must meet rigorous safety standards. Proper preparation ensures that the milling process goes smoothly and the final product meets or exceeds the required specifications.

Checklist Before Starting CNC Milling for Aerospace Parts

- [ ] Material Selection: Confirm the right material (e.g., titanium, aluminum alloys) based on the part’s function and stress factors.

- [ ] Tool Calibration: Ensure all milling tools are properly calibrated for precision.

- [ ] Design Review: Double-check the design specifications, tolerances, and dimensions.

- [ ] Machine Setup: Set the CNC machine parameters according to the specific part being milled.

- [ ] Safety Protocols: Ensure all safety measures are in place, considering the high-speed operations.

- [ ] Coolant and Lubrication: Ensure availability and proper application to prevent excessive heat and friction.

- [ ] Test Run: Conduct a pilot run, if possible, to identify any potential issues.

- [ ] Quality Assurance Protocols: Set up procedures to regularly check and verify the quality and dimensions of the part during production.

- [ ] Backup Plans: Have contingency plans for any machine or tool malfunctions.

- [ ] Documentation: Ensure all necessary documentation, like the operation procedure and quality checklists, are readily available.

CNC milling preparation for aerospace part manufacturing

Material for Aerospace CNC Milling

The aerospace industry is synonymous with innovation and cutting-edge technology. One of the main factors underpinning its advancements is the judicious choice of materials used in CNC milling for aerospace parts. These materials need to withstand extreme conditions like high temperatures, corrosive environments, and enormous pressures. They also play a critical role in ensuring aircraft weight is optimized, directly influencing fuel efficiency and overall performance.

Choosing the right material is thus paramount, not just for the functionality of the component but also for the safety, reliability, and longevity of aerospace equipment.

Table: Materials Used in Aerospace CNC Milling

| Material | Description | Applications |

|---|---|---|

| Titanium | Lightweight, resistant to corrosion, and able to withstand high temperatures. | Engine components, structural parts, fasteners |

| Aluminum Alloys | Light, corrosion-resistant, and possesses good thermal conductivity. | Aircraft frames, fuselages, window frames |

| Stainless Steel | Known for its corrosion resistance and strength at high temperatures. | Landing gear, exhaust components, actuators |

| Inconel | A super-alloy is known for its strength, resistance to heat, and corrosion resistance. | Jet engines, turbine blades, afterburners |

| Nickel Alloys | High resistance to both heat and corrosion. | Engine components, turbine blades, discs |

| Tungsten Alloys | High density and excellent tensile strength. | Ballast, vibration dampening, rotor blades |

| Magnesium Alloys | Extremely light with a good strength-to-weight ratio. | Gearboxes, electronic housings |

| Composite Materials | Made up of two or more materials, giving them unique characteristics. | Wingtips, fuselage components, cabin interiors |

| Copper Alloys | Good conductivity and corrosion resistance. | Electrical systems, bushings, bearings |

| Polymers | Lightweight and versatile with a variety of properties based on composition. | Interior components, insulations, seals |

| Ceramics | High melting point, low wear, and resistance to corrosion. | Thermal insulation, sensors, electronic components |

| Cobalt Alloys | Resistant to wear, high temperatures, and corrosion. | Turbine discs, combustion chambers, afterburners |

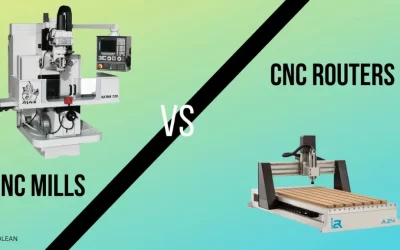

Merging CNC Milling with Other Techniques for Aerospace Manufacturing

While CNC milling is a stalwart in aerospace manufacturing, its integration with other techniques such as laser cutting, EDM (Electrical Discharge Machining), and more, results in components that are both intricate and robust. By capitalizing on the unique advantages of each process, aerospace manufacturers ensure that each component meets the rigorous demands of flight and space exploration.

Table: CNC milling & other technologies for aerospace manufacturing

| Manufacturing Process Pairing | Real-world Example | Key Advantages |

|---|---|---|

| CNC Milling & Laser Cutting | Aircraft skin production requires CNC milling for shaping and laser cutting for precise cut-outs like windows and doors. | Optimal accuracy and finish. |

| CNC Milling & EDM | Turbine blades in jet engines are shaped using CNC milling and detailed with EDM for cooling holes and intricate geometries. | Tackling intricate details and super-alloys. |

| CNC Milling & CNC Turning | Aircraft axles and shafts use CNC turning for cylindrical shaping and CNC milling for off-center features or complex geometries. | Combination of shaping and rotational cutting for precise cylindrical components. |

| CNC Milling & 3D Printing | Drone components use CNC milling for main structural parts, and 3D printing for intricate or lightweight lattice structures. | Combination of traditional shaping with futuristic additive manufacturing. |

| CNC Milling & Water Jet Cutting | Components cut from large flat sheets of metal, like certain aircraft structural parts, use water jet cutting after CNC milling. | Precise dimensions without material warping. |

Hybrid manufacturing has gained great prominence, bringing many benefits to modern industries, including aerospace. It guaranteed the production of parts that would previously be difficult to produce with only one of the individual techniques, either due to the high hardness of the material or because of the high complexity and dimensional tolerance.” Source

Summing Up

The aerospace industry is a testament to human ambition, showcasing what’s possible when cutting-edge technology meets innovative design. CNC milling stands as a cornerstone Within this confluence. It offers unparalleled precision that’s absolutely vital for aerospace applications.

CNC milling not only meets but often exceeds these expectations with its ability to handle diverse materials, achieve intricate geometries, and adhere to international quality standards. This synthesis of accuracy & efficiency with CNC milling for aerospace ensures that the industry continues to aviate, breaking barriers and setting new benchmarks.

At Prolean, we recognize the paramount importance of precision in aerospace applications. Our state-of-the-art CNC milling services are tailored to meet the unique demands of the aerospace sector, ensuring each component is crafted with meticulous attention to detail.

- Expertise: Years of experience serving the aerospace industry.

- Precision: Advanced 5-axis CNC machines that guarantee accuracy.

- Quality Control: Rigorous checks adhering to global aerospace standards.

- Material Versatility: Capability to mill a diverse range of aerospace-grade materials.

Read more:

- CNC Plastic Machining in Aerospace: A Detailed Case Study.

- What is Face Milling? Process, Tools, and Applications.

FAQs

What is aerospace CNC machining?

Aerospace CNC machining is a process that uses computer-guided tools to produce precision parts for the aerospace sector.

Why is CNC milling preferred in aerospace?

Due to its precision, consistency, and ability to handle complex geometries, CNC milling is the go-to choice for aerospace components.

How does CNC milling ensure the quality of aerospace parts?

CNC milling adheres to strict aerospace machining standards, guarantees tight tolerances, and ensures material integrity.

Are there challenges in using CNC milling for aerospace?

Yes, challenges include handling tough materials and meeting the stringent quality demands of the aerospace sector.

How does CNC milling contribute to the future of aerospace?

With the integration of advanced technologies like AI and the use of lighter materials, CNC milling is shaping the future of aerospace.

As a CNC operator, I found that checklist of Starting CNC Milling for Aerospace Parts very interesting and it is truly helpful.

Nice post! How precise can CNC milling machine the aerospace parts.