Laser marking is a non-contact printing method that is used to mark or engrave objects with high precision. This technique uses a laser beam to create permanent markings on the surface of various materials. Over the years, laser marking has become increasingly popular due to its numerous benefits, such as high precision, speed, and minimal wear and tear on the tools. It is widely used in various industries, including automotive, electronics, medical, and aerospace, among others.

This article will provide an in-depth insight into the laser marking process, its different types, such as laser engraving, laser etching, and laser annealing, and its various applications.

What is Laser Marking?

Laser marking is a broad term that encompasses various techniques used to create permanent markings on the surface of a material using a laser beam. This includes processes such as laser engraving, laser etching, and laser annealing, each of which has its unique characteristics and applications.

The laser beam, in general, interacts with the surface of the material, causing physical or chemical changes that result in a visible mark. This mark can be in the form of text, logos, barcodes, QR codes, or any other design. Laser marking is widely used across numerous industries, including automotive, aerospace, medical, electronics, and manufacturing, for applications such as identification, traceability, branding, and decoration.

The key benefits of laser marking include:

- Permanence: The markings created by laser marking are permanent and resistant to abrasion, chemicals, and heat. This makes it suitable for applications where the markings must withstand harsh conditions or last for a long time.

- Precision: Laser marking offers high precision and can create detailed and complex designs with a resolution of up to 0.1mm.

- Versatility: Laser Marking is suitable for a wide range of materials, including metals, plastics, ceramics, and composites. The versatility of laser marking makes it a preferred choice for various applications.

- Non-contact: It is a non-contact process, which means there is no physical contact between the tool and the material. This eliminates the risk of damaging the material and reduces wear and tear on the tools.

- Speed: Laser marking is a fast process, capable of creating markings in a matter of seconds, depending on the complexity of the design.

Related Resources: Plastic Laser Marking

A Deep Dive Into The Laser Marking Process

Mechanism of laser marking

Laser marking has revolutionized the way we imprint permanent markings on various materials. This non-contact method of marking, which uses a laser beam to alter the surface properties of a material, results in high-precision, permanent marks that are resistant to abrasion, chemicals, and heat. The entire process is intricate and involves several critical steps.

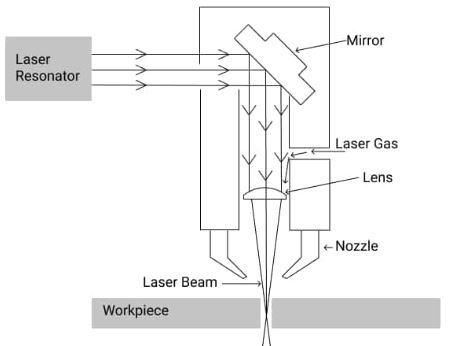

- Generation of Laser Beam The first step in the laser marking process is generating the laser beam. A laser generator produces a laser beam with the required wavelength and intensity. The type of laser used depends on the material to be marked and the desired result. For example, fiber lasers are commonly used for marking metals, while CO2 lasers are suitable for non-metallic materials like wood, plastic, and glass.

- Modulation of the Beam Once the laser beam is generated, it is then modulated. Modulation involves adjusting the laser beam’s intensity, pulse frequency, and pulse duration to suit the material being marked and the type of mark required. This step is crucial as it ensures that the laser beam interacts with the material in the desired manner, resulting in a clean and precise mark.

- Directing the Beam After modulation, the laser beam needs to be directed onto the surface of the material. This is typically done using a set of mirrors or lenses controlled by a computer. The computer directs the beam in the desired pattern on the surface of the material. The focal point of the laser beam is critical here, as it determines the size and intensity of the mark. A well-focused laser beam will result in a precise and clean mark.

- Interaction with the Material The final step in the process is the interaction between the laser beam and the material’s surface. This interaction causes a physical or chemical change in the material, resulting in a permanent mark. The exact nature of this interaction depends on the material and the laser parameters. For example, in laser engraving, the laser beam removes a portion of the material’s surface, creating a cavity. In laser etching, the laser beam melts the surface of the material, and then it solidifies, resulting in a raised mark. In laser annealing, the laser beam heats the surface of the material, causing a color change without removing any material.

Parameters Influencing the Process

Various parameters influence the laser marking process, and they need to be carefully controlled to achieve the desired results:

Table: Influencing parameters in laser marking

| Parameter | Description |

|---|---|

| Laser Power | The power of the laser beam is a critical parameter that determines the depth and intensity of the mark. Higher laser power will result in deeper marks, while lower laser power will result in shallower marks. |

| Speed | The speed at which the laser beam moves across the surface of the material also influences the quality of the mark. A slower speed will result in deeper marks, while a faster speed will result in shallower marks. |

| Focus | The focal point of the laser beam determines the size and intensity of the mark. A well-focused laser beam will result in a precise and clean mark, while a poorly focused laser beam will result in a fuzzy and imprecise mark. |

| Material Properties | The properties of the material being marked, such as its absorbance, thermal conductivity, and melting point, also influence the laser marking process. For example, materials with high absorbance will result in darker marks, while materials with low absorbance will result in lighter marks. |

Challenges in the Process

While laser marking is a highly effective and precise method for creating permanent marks on various materials, it is not without its challenges:

- Material Compatibility: Not all materials are suitable for laser marking. Some materials may melt, burn, or crack during the process, making them unsuitable for certain applications.

- Heat-Affected Zone: The heat generated by the laser beam can cause a heat-affected zone (HAZ) around the marked area. This HAZ can alter the material’s properties, making it unsuitable for certain applications.

- Surface Preparation: The surface of the material needs to be clean and free of contaminants to achieve a clean and precise mark. Surface preparation can be time-consuming and may involve additional processes such as cleaning, sanding, or coating.

What Are the Different Types of Laser Marking Techniques?

Laser marking is a versatile technique used to create permanent markings on a wide range of materials. However, it’s not a one-size-fits-all process; there are several different types of laser marking, each with its own unique characteristics, applications, and advantages. Understanding the different types of laser marking is essential for selecting the most appropriate method for your specific needs.

- Laser Engraving

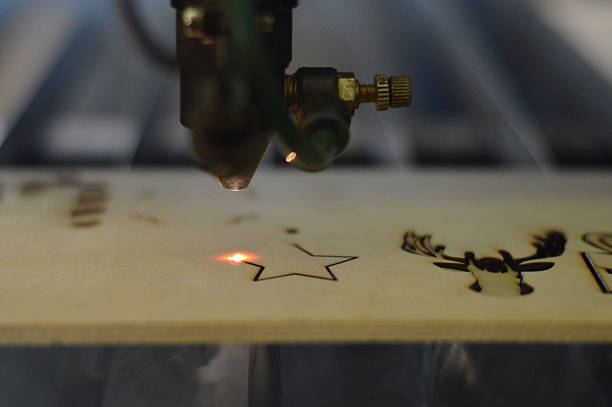

Laser engraving is a technique in which a laser beam removes portions of the material’s surface, leaving a cavity that creates a permanent, 3D mark visible to the touch. Suitable for a variety of materials such as metals, plastics, wood, glass, and ceramics, it is widely used for serial numbers, logos, and decorative designs.

Laser cutting machine cutting plywood christmas decoration.

Additionally, laser engraving offers high precision and durability, making it ideal for applications that require detailed and long-lasting markings, such as industrial components, electronic devices, and promotional products.

- Laser Etching

Laser etching involves melting the surface of the material with a laser beam, which then solidifies to create a raised mark. Ideal for high-contrast markings on metal surfaces, it is commonly used for barcodes, QR codes, and data matrix codes.

Laser etching example

Moreover, laser etching is less invasive than engraving, as it only affects the surface layer of the material. This makes it suitable for thin or delicate materials that may be damaged by deeper engraving. It is commonly used in the electronics, automotive, and medical industries for marking components with serial numbers, part numbers, and other identification codes.

- Laser Annealing

Laser annealing involves heating the surface of a material with a laser beam, causing a color change without removing any material. Suitable for metals like stainless steel and titanium that undergo color change when heated, it is commonly used for logos, text, and decorative designs.

The process is particularly useful for medical devices and surgical instruments, as it does not remove any material or create crevices where bacteria could accumulate. Additionally, it creates a smooth, corrosion-resistant surface, making it ideal for applications that require both aesthetic appeal and functional durability.

- Laser Carbon Migration

Laser carbon migration is a technique where the laser beam heats the material’s surface, causing carbon particles to migrate to the surface, creating a dark mark. Suitable for metals with a high carbon content such as steel and iron, it is commonly used for serial numbers, text, and logos.

The process results in a dark, permanent mark that is resistant to wear and corrosion, making it suitable for applications that require durable markings, such as industrial components, tools, and equipment.

- Laser Foaming

Laser foaming involves melting the material’s surface with a laser beam, creating a foam-like structure that results in a raised, textured mark. Suitable for certain plastics that produce gas when melted, it is commonly used for barcodes, logos, and text.

The resulting mark is highly visible and durable, making it suitable for applications that require high-contrast markings, such as consumer products, automotive components, and electronic devices.

Illuminating Applications of Laser Marking

Laser marking is a versatile technology with a myriad of applications across various industries. The ability to create precise, permanent, and high-contrast markings on a wide range of materials makes it an invaluable tool for manufacturers, artisans, and service providers alike.

Table: Laser marking applications

| Application Category | Sub-Category | Description |

|---|---|---|

| Product Identification & Traceability | Serial Numbers and Barcodes | Laser marking is widely used to engrave serial numbers, barcodes, and QR codes on products and components. This helps in tracking and tracing the products throughout their lifecycle, which is particularly important in industries such as automotive, aerospace, and electronics. |

| Part Numbers | Manufacturers often need to mark parts with specific numbers or codes for identification and inventory purposes. Laser marking provides a quick and efficient way to accomplish this. | |

| Medical Devices | Device Identification | Medical devices often require permanent marking for identification and traceability. Laser marking is suitable for this purpose as it can create precise, durable markings on metals and plastics without compromising the material’s integrity. |

| Surgical Instruments | Laser marking is used to create permanent markings on surgical instruments. The markings can include manufacturer information, serial numbers, or other identification codes. | |

| Electronics | Component Marking | Electronic components, such as printed circuit boards (PCBs), semiconductors, and connectors, often require precise markings for identification and traceability. Laser marking is preferred for this application due to its ability to create high-contrast markings on small surfaces without damaging the components. |

| Mobile Devices | Laser marking is used to create permanent markings on mobile devices, such as smartphones and tablets. The markings can include logos, model numbers, and other identification information. | |

| Automotive | Component Identification | Automotive components often require permanent markings for identification and traceability. Laser marking is commonly used for this purpose, as it can create durable, high-contrast markings on a variety of materials, including metals, plastics, and rubber. |

| Vehicle Identification Numbers (VINs) | Laser marking is used to engrave VINs on vehicles. This is a critical application as the VIN is essential for the identification and registration of the vehicle. | |

| Aerospace | Part Identification | Aerospace components often require permanent, high-contrast markings for identification and traceability. Laser marking is preferred for this application due to its ability to create precise markings on various materials without affecting their structural integrity. |

| Safety Instructions | Safety instructions and warning signs are often laser marked on aircraft components to ensure they are clearly visible and durable. | |

| Tooling | Tool Identification | Tools and equipment often require permanent markings for identification and inventory purposes. Laser marking provides a quick and efficient way to accomplish this. |

| Measurement Markings | Laser marking is used to create precise measurement markings on tools and equipment. | |

| Jewelry and Fashion | Designs and Logos | Laser marking is used to create intricate designs and logos on jewelry and fashion accessories. It allows for the creation of detailed and intricate designs that are not possible with traditional engraving methods. |

| Personalization | Personalized jewelry and fashion accessories are popular gifts. Laser marking allows for the creation of personalized items with names, initials, or special messages. | |

| Packaging | Expiry Dates and Batch Numbers | Laser marking is used to mark expiry dates, batch numbers, and other important information on food and pharmaceutical packaging. It ensures that the information is permanent and cannot be easily tampered with. |

| Packaging Design | Laser marking can be used to create intricate designs and branding on packaging materials. | |

| Security and Brand Protection | Anti-Counterfeiting | Laser marking can be used to create unique, permanent markings on products and components. This helps in authenticating genuine products and protecting against counterfeiting. |

| Asset Tracking | Laser marking is used to create permanent identification markings on assets, such as equipment and machinery. This helps in tracking and managing the assets throughout their lifecycle. | |

| Promotional Items | Branding | Laser marking is used to create logos and branding on promotional items, such as pens, keychains, and USB drives. |

| Personalization | Personalized promotional items are more impactful and memorable. Laser marking allows for the creation of personalized items with names, initials, or special messages. |

What Are the Laser Marking Machines?

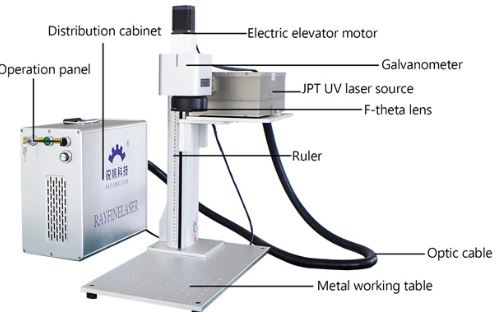

CNC laser marking machine

The core of the laser marking system is the laser marking machine. These machines come in different types and configurations, tailored for various applications and materials. The most common types of laser marking machines include fiber laser marking machines, CO2 laser marking machines, and solid-state laser marking machines.

- Fiber Laser Marking Machines: Fiber laser marking machines are the most popular type of laser marking machines. They use an optical fiber laser to generate a laser beam. These machines are known for their high peak power and good beam quality. They are suitable for marking a wide range of materials, including metals, plastics, and ceramics.

- CO2 Laser Marking Machines: CO2 laser marking machines use a carbon dioxide gas mixture as the laser medium. They are ideal for marking non-metallic materials such as wood, leather, glass, and acrylic. CO2 lasers are also used for cutting and engraving applications.

- Solid-State Laser Marking Machines: Solid-state laser marking machines use a solid medium, such as a crystal or glass rod, to generate the laser beam. These machines are known for their high beam quality and stability. They are suitable for marking metals and some non-metallic materials.

It is crucial to select the appropriate laser marking machine for your application. Factors to consider include the material to be marked, the required mark quality, and the production speed. Additionally, the laser marking machine should be compatible with your existing production setup and meet your budget constraints.

Summing Up

The field of laser marking has evolved significantly over the years, and today, it plays a crucial role in various industries, including automotive, aerospace, electronics, medical devices, and packaging. Laser marking provides a quick, efficient, and precise way to create permanent markings on a wide range of materials. Remember that selecting the right laser marking process and machine is essential for achieving the best results. It is always advisable to consult with a laser marking professional or a reputable laser marking service provider to ensure you make the right decision for your specific application.

Prolean offers state-of-the-art CNC laser marking services. Our team of experts utilizes the latest technology and high-quality laser marking machines to provide precise and permanent markings on a wide range of materials. From product identification and traceability to branding and personalization, we cater to various applications across different industries.

FAQs

What is the difference between laser marking and laser engraving?

Laser marking is a broad term that includes several processes, such as engraving, etching, and annealing. Laser engraving is a type of laser marking where the laser beam removes a portion of the material’s surface to create a mark.

Can laser marking be used on any material?

Laser marking is suitable for a wide range of materials, including metals, plastics, ceramics, and composites. However, the suitability of laser marking for a specific material depends on its properties and the type of laser marking process used.

Is laser marking permanent?

Yes, the markings created by laser marking are permanent and resistant to abrasion, chemicals, and heat.

How deep can laser marking go?

The depth of laser marking depends on the type of process used and the material being marked. For example, laser engraving can create marks with a depth of up to 0.5mm, while laser etching only affects the surface of the material.

Can laser marking be done in color?

Yes, laser marking can create color marks on certain materials, such as stainless steel and titanium, by using a process called laser annealing.

Is laser marking safe?

Yes, laser marking is a safe process when proper safety measures are followed. It is essential to wear safety goggles to protect your eyes from the laser beam and to operate the laser marking machine in a well-ventilated area

Hey, it is really good content, thanks for sharing