Computer Numerical Control (CNC) technology has continuously evolved, leading to innovations that reshape manufacturing landscapes. Among them, the 5-axis CNC machine stands out as a transformative tool, granting unparalleled precision and flexibility in complex machining tasks. By providing movement along five different axes simultaneously, it transcends the capabilities of its 3-axis and 4-axis predecessors.

This article delves into the intricacies of 5-axis CNC machines, highlighting their features, advantages, and their pivotal role in today’s manufacturing world.

The Fundamentals: Deciphering the 5-Axis Concept

The realm of Computer Numerical Control (CNC) machining is vast, with advancements regularly redefining its boundaries. Among these advancements, the concept of 5-axis machining stands tall as a paradigm-shifter. To understand its significance, we must first decode what “5-axis” truly means and how it compares to its predecessors.

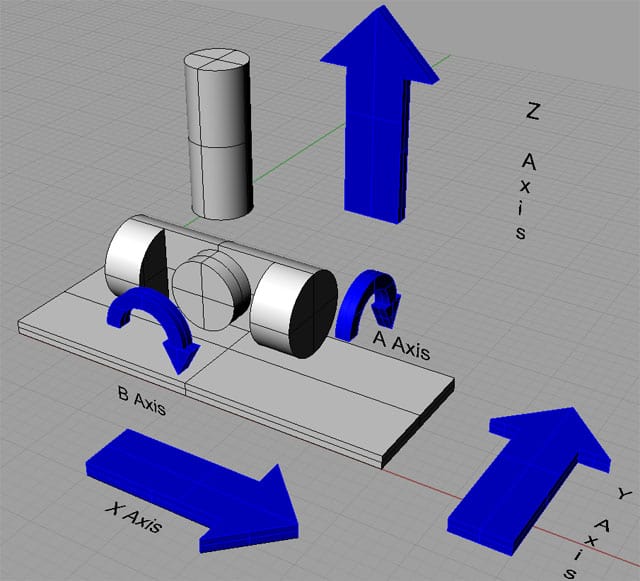

At the foundation of CNC machining, the X, Y, and Z axes form the cornerstone. These represent the three primary directions of movement. The X-axis typically corresponds to movements that are horizontal and run parallel to the workbench. The Y-axis aligns with vertical movements perpendicular to the bench. Lastly, the Z-axis involves depths, dictating how far into or out of the material the tool travels.

The trio offers a decent range of motion, and many conventional machining tasks revolve around this 3-axis framework. The system excels at milling, drilling, and more. However, as designs grew more intricate and applications more demanding, the need for more axes emerged.

Entering the World of Rotary Movements

Beyond the cardinal three axes, the world of multi-axis CNC machining introduces rotary movements. These additional axes are usually termed A, B, or C axes:

Table: Axes in machining operations

| Axis | Description | Example |

|---|---|---|

| A-axis | Rotation around the X-axis | A log turning on a lathe, where the spindle rotates horizontally |

| B-axis | Rotation around the Y-axis | Tilting from front to back, allowing the tool or the workpiece to tilt |

| C-axis | Rotation around the Z-axis | Spinning, like a potter’s wheel, can be applied either to the workpiece or the tool, depending on the machine’s configuration |

It’s crucial to note that not all 5-axis CNC machines have the same combination of rotational axes. The machine’s design could involve the tool moving, the workpiece moving, or a mix of both.

Unveiling the ‘5’ in 5-Axis & Real-world Implications

With a basic understanding of the primary three and the additional rotary axes, we now venture into the realm of 5-axis machines. These marvels of engineering can operate in all five axes simultaneously. This simultaneity is their magic wand.

Imagine sculpting a statue. With a 3-axis machine, you’d have to turn the statue manually to carve out its different sides and angles. But with a 5-axis machine, the tool can approach the statue from virtually any angle without manual intervention. This capability opens the door to immense precision, complex geometries, and enhanced efficiency.

Real-world Implications

In the world of engineering and design, angles and contours can make or break a component’s functionality. Whether it’s the aerodynamics of a race car component or the ergonomic design of a medical tool, angles matter.

The 5-axis machine, with its intricate movement capabilities, ensures these angles are achieved with unparalleled precision. For instance:

- Aircraft Components: When crafting components like turbine blades, the ability to machine complex curves and precise angles is crucial. This accuracy not only affects the component’s efficiency but also the safety of the entire aircraft.

- Medical Prosthetics: Human anatomy is intricate, and prosthetics require a perfect fit. The multi-angled machining capability ensures that prosthetics are tailored to individual anatomical needs.

How Does a 5-Axis CNC Machine Work?

5 Axis machining

The realm of CNC machining has undergone significant advancements, and the 5-axis CNC machine stands at the forefront of this technological evolution. To truly appreciate the capabilities of this machinery, understanding its working mechanism is paramount.

The Fundamental & Mechanics of Axes

As previously mentioned, the term “5-axis” refers to the number of directions in which the cutting tool can move. In a 3-axis machine, the tool moves up and down, left and right, and forward and backward. These are termed as X, Y, and Z axes, respectively. The 5-axis CNC machine incorporates two additional rotational axes, known as A and B (or sometimes C), which allow the workpiece to be rotated and tilted, providing additional access points for the cutting tool.

Movement of the tool in 5-axis CNC machine

1. The Underlying Mechanics

The actual mechanics behind a 5-axis CNC machine can be understood as a synergistic dance between the movement of the workpiece and the cutting tool. This simultaneous movement is what allows the machine to produce complex geometries.

Table: Mechanics of CNC machine

| Movement | Description |

|---|---|

| Workpiece Movement | The machine table, holding the workpiece, can rotate from a vertical to a horizontal position. This rotation is typically managed by the A and B axes. The capability to move the workpiece in this manner means that multiple sides of the part can be accessed without manual repositioning. |

| Cutting Tool Movement | Along with the traditional X, Y, and Z axes found in 3-axis machines, the cutting tool in a 5-axis CNC machine can approach the workpiece from virtually any direction. This is accomplished through sophisticated software and hardware that govern the tool’s movement and ensure its precise alignment with the designated cutting path. |

2. The Role of Sophisticated Software

No discussion about the workings of a 5-axis CNC machine can be complete without highlighting the indispensable role of software. Advanced Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software programs are used to design the part and then generate the necessary machine path.

The software determines the most efficient and effective way to move both the tool and the workpiece to produce the desired part. This involves calculating the best angles and sequences for cuts, ensuring optimal speed and precision.

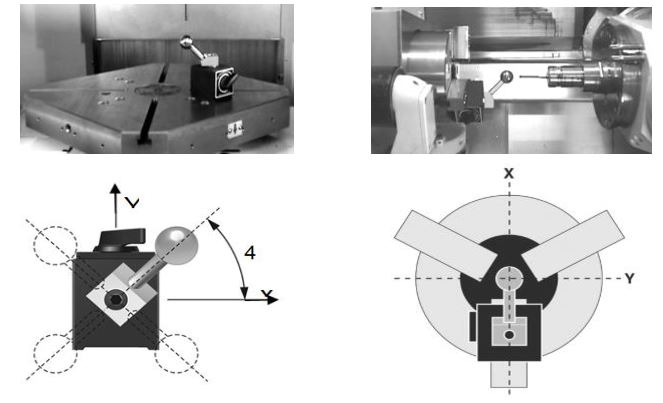

Tool Compensation and Calibration

One of the challenges in 5-axis machining is maintaining accuracy when the tool is moving along multiple axes simultaneously. To counteract potential inaccuracies, the machine employs tool compensation techniques. This involves continuously adjusting the tool’s position based on real-time feedback to ensure that it remains on the correct path.

5-axis machining tool calibration

Furthermore, calibration plays a crucial role. Regular calibration ensures that the machine’s movements align with the software’s specifications, leading to parts that adhere closely to their intended designs.

Continuous vs. Positional 5-Axis Machining

There are primarily two modes of operation for 5-axis CNC machines:

Table: Continuous vs. Positional 5-Axis Machining

| Machining Mode | Description | Applicable Parts |

|---|---|---|

| Continuous 5-Axis Machining | All five axes work simultaneously throughout the cutting process | Intricate parts where the tool needs to maintain a continuous path or for parts that have complex, free-form surfaces |

| Positional (or 3+2) Machining | The machine positions the workpiece in the required orientation using the rotational axes and then locks it in place. The actual cutting is then done using the traditional three axes | Parts that need machining on multiple sides but don’t require continuous 5-axis movement |

The working of a 5-axis CNC machine can be visualized as a harmonious choreography of movement between the workpiece and the tool. This choreography is orchestrated by advanced software, monitored by sensors, and realized by precise mechanical components. Together, these elements ensure that a block of material can be transformed into a complex, precise component, fulfilling the requirements of industries that demand nothing less than perfection.

Notable Features of 5-Axis CNC Machines

Within the vast landscape of machining, 5-axis CNC machines have carved a distinct niche. Their revolutionary design and advanced functionalities set them apart from traditional machining options. Now, lets dive deep into the key features that make 5 axis CNC machine the giants of precision and versatility they are today.

Enhanced Precision and Accuracy

At the heart of the 5-axis CNC machine is its promise of exceptional precision. The ability to manipulate a workpiece along five different axes simultaneously ensures that the tool can access any part of the piece without the need for manual adjustments or re-fixturing. This reduces errors that can arise from multiple setups.

Furthermore, since the workpiece remains in one setup, there is less chance of error due to resetting. The tool can make complex cuts, angles, and shapes in one go, ensuring that each cut is as precise as the design mandates.

Complex Geometries and One-Setup Machining

Traditional machining methods often struggle with intricate designs or parts that have undercuts, strange angles, or complex geometries. The 5-axis CNC machine thrives in these scenarios. By moving along five different axes, the tool can approach the workpiece from virtually any direction, allowing for the creation of shapes and features that would be impossible or highly time-consuming on 3-axis machines.

Reduced Tool Wear and Increased Tool Life

An often-underestimated feature of the 5-axis CNC machine is its impact on tool life. Due to the machine’s ability to maintain optimal cutting positions and consistent chip loads, there’s a significant reduction in tool wear. The machine can position itself in such a way that the tool engagement remains consistent, ensuring that there’s a uniform load on the tool.

This uniformity doesn’t just lead to better finishes but also ensures that the tools themselves last longer. For industries where precision is paramount, and tool replacement can be expensive, this extended tool life can lead to considerable cost savings.

Advanced Software and Control Systems

The backbone of any CNC machine, especially those as advanced as the 5-axis variants, is its software and control system. These machines come equipped with state-of-the-art software solutions that can handle complex operations, simulations, and real-time adjustments.

For instance, the machine’s control system constantly evaluates the tool’s position and adjusts it in real-time to maintain optimal engagement with the workpiece. Such dynamic adjustments are crucial when working on intricate parts, ensuring that the machine’s output mirrors the design’s specifications closely.

Flexibility in Workpiece Sizes

Contrary to what some might think, 5-axis CNC machines aren’t just for tiny, intricate parts. They can accommodate a range of workpiece sizes. From small, delicate components for medical applications to larger parts used in automotive or aerospace industries, the flexibility in terms of workpiece size is vast. The machine’s design ensures that even if the workpiece is large, the tool can still access it from multiple angles, making the most of the 5-axis capabilities.

Safety and Collision Avoidance

Modern 5-axis CNC machines come equipped with advanced collision detection and avoidance systems. Given the complexity of operations these machines perform, there’s always a risk of the tool colliding with the workpiece or the machine itself. Advanced sensors and software algorithms work in tandem to predict potential collisions and adjust the machine’s movements to avoid them.

What Are the Advantages of 5-Axis CNC Machining?

The 5-axis CNC milling machine cutting the sample of aluminium engine parts by solid ball endmill tools. The automotive parts manufacturing process by 5-axis machining center.

5-Axis CNC machining process

5-Axis CNC machining, a methodology that once felt like something from a futuristic movie, has solidified its importance in the modern manufacturing sector. These machines can move in five different directions simultaneously, granting unparalleled advantages. Below, we explore the intrinsic benefits that set this technology apart.

- Superior Surface Finishes

One of the immediate advantages is the ability to achieve smoother surface finishes. By maintaining the optimal cutting angle throughout the process, 5-axis machines reduce the time the tool spends in the cut, minimizing the risk of tool deflection. This results in parts with cleaner finishes and sharper details.

- Complex Geometry & Intricate Designs

For manufacturers working on projects that involve intricate geometries or unique shapes, 5-axis machining is a game-changer. The movement flexibility ensures that almost any conceivable shape or profile can be achieved with fewer setups, thus maintaining high precision.

- Reduced Setup Times

Historically, complex parts required multiple machine setups, with the workpiece being repositioned after each phase. With 5-axis machining, the number of setups is drastically reduced, as the machine can access most sides of a part in a single setup, saving both time and labor costs.

- Enhanced Tool Life

The continuous toolpath enabled by 5-axis machining minimizes sudden changes in direction and reduces the toll on the cutting tool. Consequently, tools wear out less quickly, extending their operational life and reducing replacement costs.

- Cost Savings in the Long Run

While the initial investment in 5-axis CNC machinery might be higher than its 3-axis counterparts, the cumulative advantages—reduced labor, faster production times, fewer errors, and less waste—translates to significant cost savings over time.

- Increased Competitive Edge

For businesses, adopting 5-axis machining isn’t just about efficiency; it’s about staying competitive. With the ability to produce more complex parts faster and with greater precision, manufacturers can meet client demands more effectively and secure contracts that were previously out of reach.

The Applications: Industries Leveraging 5-Axis Machining

The versatility of 5-axis CNC machines has made them favorites across a myriad of industries. Each sector has its unique requirements, and the adaptability of 5-axis machining makes it the tool of choice for many.

Custom steel part created with 5-axis CNC machining

Now, let’s take a closer look at some industries that are incorporating this technology into their production lines.

Table: Industry-Specific Applications of 5-Axis CNC Machining

| Industry | Description | Key Applications |

|---|---|---|

| Automotive | As car designs evolve to incorporate intricate features for both aesthetic and functional reasons, the automotive industry heavily relies on 5-axis machining. | Engine components, custom fixtures, and old-making for interiors. |

| Medical | The medical sector requires components that are both precise and biocompatible. | Dental implants, orthopedic devices, and specialized surgical tools. |

| Energy | This sector, particularly in renewable energy, demands parts that can endure extreme conditions. | Turbine parts (requiring perfect balance and high durability). |

| Jewelry & Art | Beyond the traditional heavy industries, artisans are turning to 5-axis machining for their crafts. Intricate jewelry designs or sculptures that blend artistry with precision benefit immensely from this technology. | Detailed jewelry designs & Intricate sculptures |

| Research & Development | In areas like material science or mechanical research, there’s often a need for custom components. The flexibility and precision of 5-axis machining are pivotal for researchers working on prototypes or other specialized tools and equipment. | Custom components for material science experiments, prototypes for mechanical research, and specialized equipment for various research needs. |

Summing Up

The 5-axis CNC machine, with its intricate design capabilities and efficiency, is undeniably a game-changer in the manufacturing domain. By understanding its nuances, advantages, and potential challenges, industries can harness its full potential, ensuring products that are not just precise but also superior in quality. As the future of manufacturing leans more towards automation and precision, the 5-axis CNC machine stands tall as a testament to technological advancement.

For those looking to harness the full potential of 5-axis CNC machining, Prolean offers an array of services. With a focus on precision, quality, and efficiency, Prolean ensures that every manufacturing requirement is not just met but exceeded.

FAQs

What differentiates a 5-axis CNC machine from its 3-axis counterpart?

A 5-axis machine can move in five different directions simultaneously, unlike a 3-axis machine which operates only in X, Y, and Z directions.

Is training necessary to operate a 5-axis machine?

Yes, for those accustomed to traditional machines, training might be essential to grasp the full potential of 5-axis machining.

How does 5-axis machining enhance tool life?

Due to its movement flexibility, there’s the lesser strain on tools, leading to reduced wear and longer tool life.

In what industries is 5-axis CNC machining most commonly used?

Aerospace, automotive, entertainment, and medical industries prominently use 5-axis machining for their intricate manufacturing requirements.

Why choose Prolean’s CNC Machining Services?

Prolean offers precision, quality, and efficiency, ensuring all your 5-axis CNC machining requirements are surpassed.

0 Comments