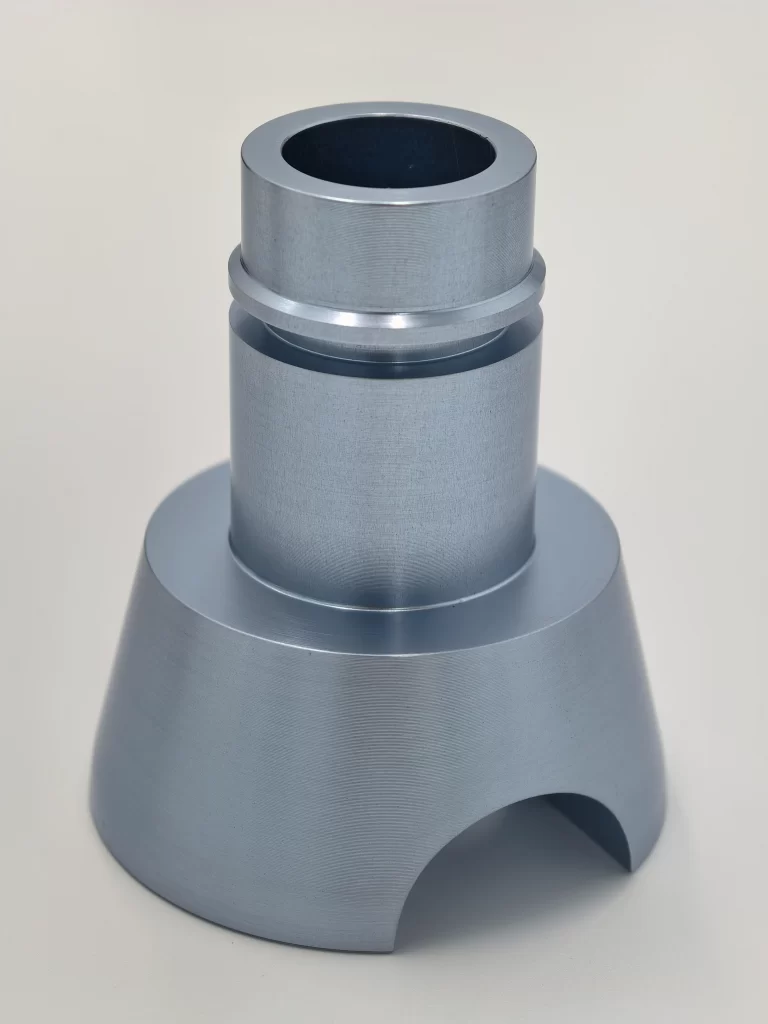

SURFACE FINISHING

Anodizing

Anodizing is the process of developing a layer of aluminum oxide (Al2O3) on the surface of the aluminum and its alloys through the electrolysis process.

All uploads are secure and confidential.

Introduction

Anodizing is the process of developing a layer of aluminum oxide (Al2O3) on the surface of the aluminum and its alloys through the electrolysis process.

After anodizing, the surface becomes super resistive to corrosion and enhances the other mechanical properties of wear resistance and hardness.

The anodizing process easily achieves various colors, such as black, blue, gold, grey, and red. It can maintain a surface roughness not lower than Ra 3.2μm.

It is used in various industries, including automobile, architecture, aerospace, home appliances, etc.

.

key properties

Get Your Parts Made Today

All uploads are secure and confidential.