CAPABILITIES

Overmolding Service

Industries including robotics, medical and automotive use overmolding for manufacturing aesthetically pleasing products or to reduce the assembly line stations. Overmolding offers a more convenient solution for injection molded products with two or more materials.

Prolean’s overmolding services offer all the different combinations for overmolded parts with a wide range of materials to choose from.

All uploads are secure and confidential.

What is Overmolding?

How to Order Parts?

Get a free quote from a real engineer; once we receive your design, our engineer will review it and send you a quote as fast as one hour.

Get A Quote Immediately

Upload your design or email our engineer directly and get your quotes as fast as one hour.

Start Production

Your parts will be made once your orders are confirmed. Besides, you will get real-time order updates of the production status from our order tracking system.

Receive Your Part

After all parts pass QC inspection, they will be well packed from transportation accidents. Then, your custom parts are delivered straight to your doorstep.

Overmolding has one primary advantage. One machine can generate multiple pieces of the part directly on each other. This reduces the number of machines and assembly line stations required which saves a large amount of time and money.

Overmolded parts have a broad range of applications due to their composite nature. Grips, seals, insulation, and vibration-absorbing layers are often over-moulded on products.

What Materials Are Available For Overmolding?

| Thermoplastics | |

| ABS | PET |

| PC | PMMA |

| Nylon (PA) | POM |

| Glass Filled Nylon (PA GF) | PP |

| PC/ABS | PVC |

| PE/HDPE/LDPE | TPU |

| PEEK | |

Finishing Options For Overmolding Product

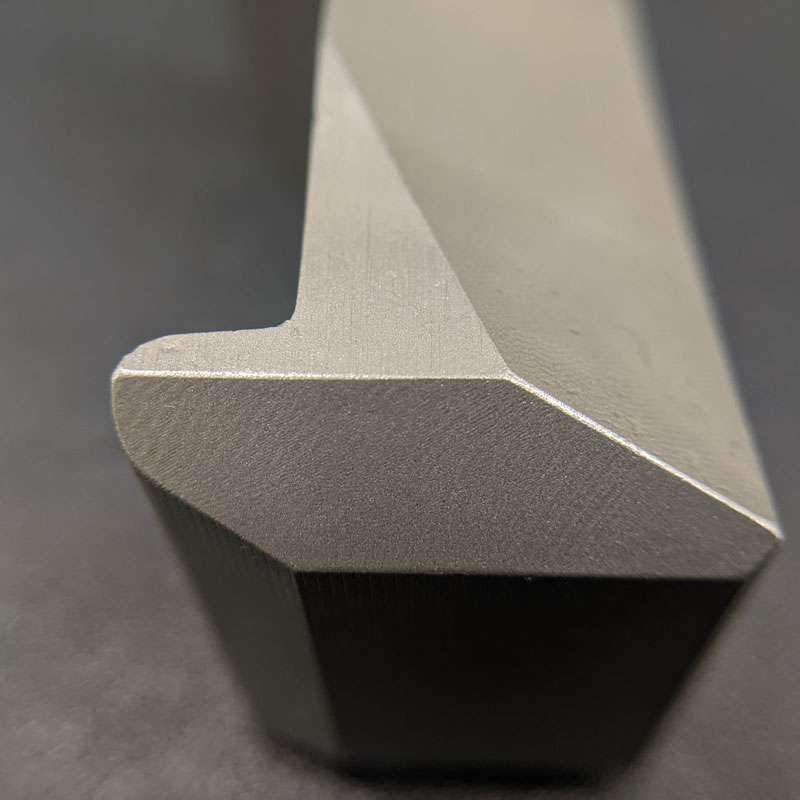

As the machined or deburring

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

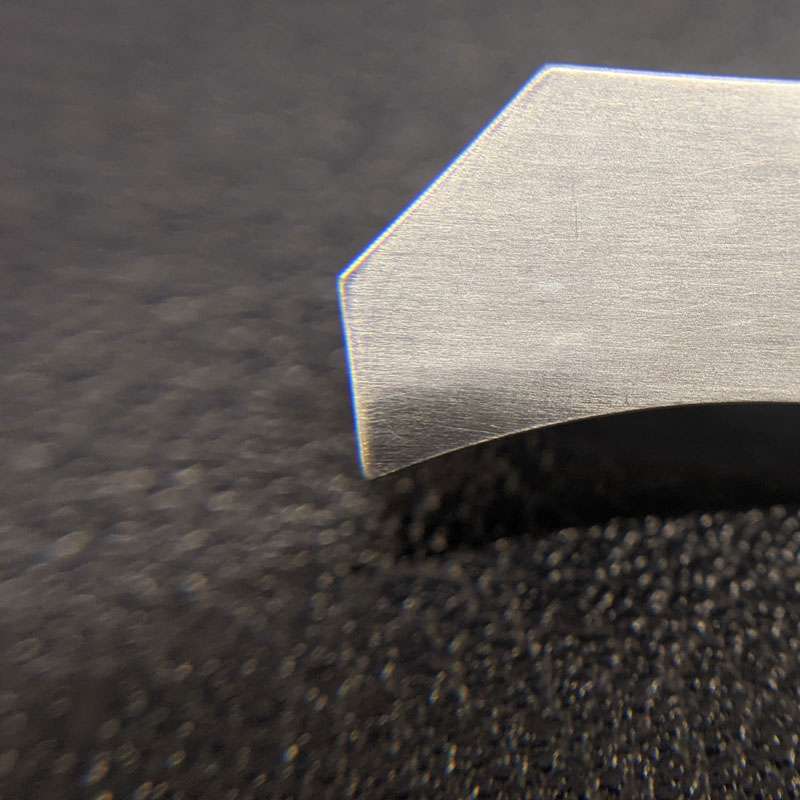

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Powder coating

Powder coating is the electrostatically applying of dry powder to the surface. It produces a thin layer providing excellent resistance to wear, corrosion, and abrasion.

PTFE (Teflon) Coating

The Teflon layer on the parts offers excellent corrosion resistance, water resistance, and non-stickiness with a non-reactive surface.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Smooth machining

Smooth machining is done by controlling the machining process, such as feed rate & cutting speed. It minimizes the tool marks and risk of corrosion.

More

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

3 Ways to Ensure Perfection

Standards

GENERAL TOLERANCE

For metals, the standard is ISO-2768 fH (fine)

For plastics, the standard is ISO-2768 mK (medium)

Metric threads tolerances:ISO 965-1 standard UN Threads Tolerances: ASME B1.1-2003 standard

knurling: ISO13444:2012 standard Our factory is ISO 9001:2015 certificated

Visual inspection and Protection

Constant visual inspection conditions

Quantification of cosmetic surface quality

Process requirements

Part cleaning and Protection

Quality Inspection Report

Inspection Confirmation

Dimensional confirmation

Appearance confirmation

Quality documentation

Try Prolean Now!

See why customers dig us

I am especially pleased with how you provided the overmolding prototypes for adjusted design each time before full-scale production. Thank you!

-Jonathan Meyers, Senior Prototyping Engineer at InnovateMold Solutions

Excellent grips on my tool holders and I am fully satisfied with the results. I don’t think anyone will meet the collaboration spirit of Proleantech’s Engineers.

-Emily Carter, Director of Product Development

Our remote control housings arrived today! All of them are according to specifications and surface polishing looks nice too! We will surely collaborate in the future.

-Mark Johnson, Lead Manufacturing Engineer at Prototype Edge

These polypropylene toothbrushes look great and perfectly functional as we needed. We will customize the surface texture and color next time. Thank you for the timely delivery.

-Sarah Thompson, Head of R&D

We received the insulated cable assemblies, and they are perfect! The flexibility and durability are exactly what we needed. Your team’s dedication and clear communication has been invaluable.

-Michael Harrison, CastForm Technologies

Related Blog

Injection Molding Vs Extrusion: What’s The Difference?

Injection molding creates complex 3D parts, extrusion produces continuous profiles efficiently.

Extrusion Molding vs Injection Molding: Which Works Best?

Injection molding makes complex plastic parts; extrusion molding creates long, uniform shapes

Exploring Hot Runner vs Cold Runner Injection Molding

Hot runner injection molding and cold runner injection molding

Get Your Parts Made Today

All uploads are secure and confidential.