MATERIALS

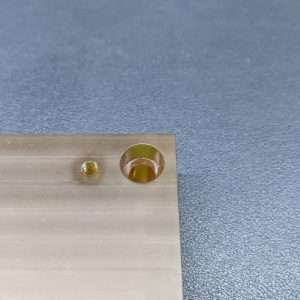

Polyetherimide (PEI)

Semi-transparent, high strength, rigidity, thermal stability, chemical inertness, and dimensional stability. Parts made from PEI can work for an extended period without stress cracking.

Polyetherimide (PEI)(ULTEM)

| Process compatibility | Applications | Tolerances | Wall Thickness | Max Part Size | Strengths | Lead Time | Price |

| CNC Mill CNC Lathe | Voltage breakers, carburetor housings, microwave housing, medical, chemical instruments, and aerospace parts. | Not lower than ±0.25 mm (±0.010″), based on the drawing ( ISO 2768) | Minimum 0.03″ (0.80 mm), but this can change depending on the proportion of the wall thickness to the linear dimension. | 200 x 80 x 100 cm | Semi-transparent, high mechanical strength, rigidity, thermal stability, and chemical inertness. | Minimum 3 days. Not more than 10 days; for all complex parts. | $ |

Introduction to Polyetherimide (PEI)

PEI provides a high degree of creep resistance, weather stability, chemical resistance, Stiffness, stress cracking resistance, Dimensional stability, and fair electrical conductivity.

Because of these flexible properties, It is suitable for fabricating voltage breakers &carburetor housings, microwave housing, medical and chemical instruments, aerospace parts, and many more.

Get Your Parts Made Today

All uploads are secure and confidential.