CAPABILITIES

Galvanizing Service

Prolean offers ISO 9001:2015 certified, exceptionally durable galvanizing services, which will give you the best quality and most elegant look.

- Coating Thickness: 85-200 μm

- ASTM D6386, D7803 Standards

- Enjoy Lead Time as minimum as 1 day

All uploads are secure and confidential.

Our Galvanizing Service

Discover Prolean’s proven, top-of-the-line, eco-friendly galvanizing solutions that feature accuracy and creativity to keep your parts built to last.

Our high-quality galvanized layers protect steel and alloys from rust caused by the effects of air and moisture. The hard zinc oxide layer not only strengthens the part but also enhances its appearance. Our skilled staff is dedicated to achieving high-quality results that deliver sustainable benefits, striking a balance between strength and aesthetics.

Prolean offers quality solutions for the automotive, construction, aerospace, electronics, and agriculture sectors, making your investment in our galvanizing services both reasonable and valuable.

Our Galvanizing Capabilities

| Capability | Description | Specifications | Finishing Options | Unique Features |

| Hot Dip Galvanizing | Immersion in molten zinc for comprehensive coating. | 85-200 μm, (ASTM D6386, D7803), | Passivation, chromate conversion | Excellent durability and decades of longevity; ideal for large, complex structures. |

| Electroplating | Precision zinc coating is applied through electrical deposition. | 5-25 μm | Bright finish, chromate conversion, passivation | High precision and uniformity; ideal for small, intricate components. |

| Thermal Diffusion Galvanizing (Sherardizing) | Zinc alloy coating is applied through a diffusion process. | 10-30 μm | Bright finish, passivation | Offers a very thin, uniform coating with high adhesion and corrosion resistance. |

| Zinc Thermal Spray (Spray painting) | Zinc coating is applied through a thermal spray process. | 100-300 μm | Passivation, topcoats | High build-up capability; suitable for large or irregularly shaped components. |

Try Prolean Now!

Our Galvanization Process

1. CNC Surface Finishing Preparation

This step makes the surface clean and smooth to provide the best surface for the zinc to stick to. The use of CNC machinery reduces the surface roughness of the metal and eliminates any impurities, rust, and mill scale on the surface of the metal before galvanizing. This preparation makes the zinc coating stronger and more efficient as compared to those that receive a single coat.

2. Galvanizing Treatment

The actual galvanizing is done by dipping the metal components that have been prepared into a kettle containing molten zinc. This process forms a series of zinc-iron alloy layers with a metallurgical bond with the base metal and pure zinc layer on the surface. This makes it possible to have the highest protection against corrosion and a durable barrier to the metal surface.

3. Post Treatment

Our post-treatments include rinsing in a passivation solution, chromate dipping, and sealants to improve aesthetic properties and enhance corrosion protection, making components ready for immediate use.

Advantages of Galvanizing Process

- Good Protection

The galvanizing process provides superior protection, and complete coverage against corrosion by forming a protective hard coating.

The Galvanized layer is capable of healing itself if it gets scratched and therefore preserves the metal and does not rust.

- Save Money

It greatly minimizes upfront maintenance required, which means cutting down on the amount of money that would be spent on repairing the building in the future.

Galvanized metal is more durable than other types of metal and thus requires less replacement, thus saving money.

- Environmental-friendly

The process also promotes environmental sustainability through product durability and full recyclability of the product.

Employing galvanized steel helps to save resources and has a lesser effect on the environment.

Materials for Galvanizing

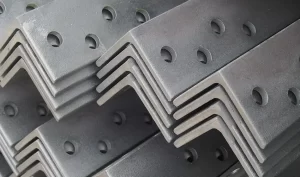

Steel and Iron

The most preferred materials to be galvanized are steel and iron because of their strength and versatility in applications such as construction and automotive industries. The galvanizing done by our team improves their anti-rust and anti-corrosion features and therefore enhances their lifespan. The process creates a layer of zinc that bonds with the steel or iron and then creates layers of zinc-iron alloy and an outer layer of pure zinc.

Alloy Steels

Other types of steel are steel alloys which are produced by adding steel with other elements to improve its characteristics like strength and wear. Our professionals ensure that the process of galvanizing is well done with certain alloying additions. This may need some form of pre-treatment or some form of preparation to ensure that the coating adheres well and is of good quality.

Cast Iron

The use of galvanizing both ductile and malleable cast iron is also done although not as frequently as that of steel. Our specialists describe the problems related to high-carbon cast iron, which can lead to the formation of graphite during galvanizing. Regarding the pre-treatment process, abrasive blasting is applied to the cast iron before proceeding with the galvanizing process.

Steel and Iron

Steel and Iron

The most preferred materials to be galvanized are steel and iron because of their strength and versatility in applications such as construction and automotive industries. The galvanizing done by our team improves their anti-rust and anti-corrosion features and therefore enhances their lifespan. The process creates a layer of zinc that bonds with the steel or iron and then creates layers of zinc-iron alloy and an outer layer of pure zinc.

Alloy Steels

Alloy Steels

Other types of steel are steel alloys which are produced by adding steel with other elements to improve its characteristics like strength and wear. Our professionals ensure that the process of galvanizing is well done with certain alloying additions. This may need some form of pre-treatment or some form of preparation to ensure that the coating adheres well and is of good quality.

Cast Iron

Cast Iron

The use of galvanizing both ductile and malleable cast iron is also done although not as frequently as that of steel. Our specialists describe the problems related to high-carbon cast iron, which can lead to the formation of graphite during galvanizing. Regarding the pre-treatment process, abrasive blasting is applied to the cast iron before proceeding with the galvanizing process.

Types of Galvanizing Process

Hot Dip Galvanizing

Prolean engineers use hot dip galvanizing where the metal parts are dipped in molten zinc. It forms a strong and anti-corrosive layer which is suitable for structural steel and other applications in the exterior. This process of creating a thick zinc layer offers a protective barrier that is long-lasting and resistant to extreme environmental conditions.

Sherardizing

Sherardizing is a diffusion process that involves the heating of objects with zinc dust and an insusceptible material such as sand. This procedure is commonly conducted in a closed rotating drum at a temperature of 320-500°C. Once the zinc/iron alloy coating has been developed, the items are then treated with zinc phosphate to obtain a fresh surface. The coating spreads and adheres to the base material and ensures that it covers the items uniformly regardless of the shape that the latter has.

Electroplating

Electroplating is the process of coating an object with a layer of metal through electrodeposition. It involves using controlled electrolysis to transfer metal from an anode (the metal source) to a cathode (the object to be coated), with an electric current passing through an electrolytic bath solution. Electroplating is commonly used to apply a layer of a less expensive metal, like nickel or copper, onto a base metal.

How to Order Parts?

Get a free quote from a real engineer; once we receive your design, our engineer will review it and send you a quote as fast as one hour.

Get A Quote Immediately

Upload your design or email our engineer directly and get your quotes as fast as one hour.

Start Production

Your parts will be made once your orders are confirmed. Besides, you will get real-time order updates of the production status from our order tracking system.

Receive Your Part

After all parts pass QC inspection, they will be well packed from transportation accidents. Then, your custom parts are delivered straight to your doorstep.

Applications of Galvanization

Agriculture, and Farming

Galvanizing is commonly used in agriculture to protect equipment and structures from corrosion, preventing rust and reducing maintenance costs. It provides reliable and economical protection for barns, trailers, feeding equipment, and support structures, contributing to efficient and sustainable farming practices.

Construction and Infrastructure

In construction and infrastructure, galvanizing enhances the corrosion protection of metal parts. We use galvanized steel in structural frames to protect them from harsh weather, reducing the need for frequent repairs.

Automotive and Transportation

In automotive and transportation, galvanizing is very vital in eliminating the rusting of auto parts such as body, frames, and chassis. The process ensures that cars and trucks are well-maintained and thus do not need frequent repairs.

Energy and Utilities

We apply this process to protecting parts in power plants, electrical networks, and renewable energy plants like windmills. Since the galvanized components are strong and durable, they can be used in hard areas to reach hence ensuring the longevity of energy systems.

HVAC and Ventilation Systems

In HVAC and ventilation systems, galvanizing prevents the ducts, pipes, and structural parts from corroding. This protection contributes to the effectiveness of the heating, ventilation, and air conditioning systems and their longevity. The moisture and temperature do not have any impact on the galvanized components hence they do not need frequent maintenance.

Renewable Energy

The renewable energy industry employs the process of galvanizing to protect solar panels, wind turbines, and other structures. Steel coatings also can perform well in extreme environmental conditions; therefore, green energy systems are long-lasting. This corrosion resistance is important for the sustainability of renewable energy structures and therefore helps in the provision of clean energy with minimal maintenance.

Galvanized Parts Gallery

Galvanizing FAQs

What is the general technique of the galvanization process?

What are the common types of achieving galvanization?

Why use galvanization?

What are the applications of galvanization?

Can all metals be galvanized?

Get Your Parts Made Today

All uploads are secure and confidential.