CAPABILITIES

CNC Drilling Service

We offer CNC drilling for prototypes and production parts, with quotes from a real engineer in one hour and production in as little as one day.

- Multi-Axis (3, 4, or 5-axis) Drilling

- Works with Aluminum, Steel, Copper, Polymers, etc

- Certified quality with detailed inspection reports

- Customized CNC machining and drilling

All uploads are secure and confidential.

What is CNC Drilling?

CNC drilling is a computer-controlled machining process that uses a rotating drill bit to create round holes in materials like wood, metal, plastic, or composites.

Unlike manual drilling, CNC drilling utilizes 5-axis drilling software to automate the operation. This software directs and positions the drill bit, making the process more efficient and precise.

The machine creates clearance holes, which are used for assembly with fasteners such as bolts or screws. This automation ensures faster, more accurate drilling compared to traditional manual methods.

Try Prolean Now!

Why Choose Our CNC Drilling Service

Comprehensive Quality Assurance: Provides certificates of compliance, raw material certificates, and detailed inspection reports.

5-Axis Drilling Centers: Enables turning parts and drilling cross holes both on and off-center.

Efficient Coolant Systems and Drill Range: High-pressure coolant systems and a wide range of HSS, carbide, and inserted drills ensure high-quality results.

Comparing Different CNC Drilling Types

| Factors | CNC Drilling | Reaming | Micro Drilling | Center Drilling |

| Primary Use | Initial hole creation in solid materials | Finishing and sizing pre-drilled holes | Drilling tiny holes | Preparing holes for accurate drilling |

| Hole Diameter Range | Up to 80 mm | Up to ~80 mm | Less than 0.1 mm (often much smaller) | Typically, up to 25 mm |

| Tolerance | ±0.001” (hole placement), ±0.0002” (repeatability) | IT9 to IT7 (dimensional accuracy) | Typically ±0.002 mm or finer | ±0.01 mm |

| Surface Roughness | Ra 50 – 12.5 μm | Ra 3.2 – 0.8 μm | Ra 0.8 μm or finer | Ra 10 – 5 μm |

| Typical Tools | Twist drill, deep hole drill | Hand reamers, machine reamers | Micro drills, often with special coatings | Center drills, spotting drills |

| Material Compatibility | Metals, plastics, composites | Metals, plastics, composites | Metals, plastics, ceramics | Metals, plastics, composites |

How to Order Parts?

Get a free quote from a real engineer; once we receive your design, our engineer will review it and send you a quote as fast as one hour.

Get A Quote Immediately

Upload your design or email our engineer directly and get your quotes as fast as one hour.

Start Production

Your parts will be made once your orders are confirmed. Besides, you will get real-time order updates of the production status from our order tracking system.

Receive Your Part

After all parts pass QC inspection, they will be well packed from transportation accidents. Then, your custom parts are delivered straight to your doorstep.

CNC Drilling Material Options

- Low density, non-ferrous, and does not rust easily

- Used in the manufacture of aircraft and automobiles. Most suitable for application in constructing frames of buildings and other structures and machinery.

- Strong and does not corrode, suitable for use in hospitals and the kitchen.

- It is found in almost all industrial machines and equipment.

- Flexible and electrically conductive, applied to electrical conducting and ornamental purposes.

- They are used in plumbing parts and many other mechanical products.

- Lighter than steel, it is used to construct aircraft and other equipment and medical tools and equipment.

- They are also used in other superior auto parts and marine merchandise.

- High electrical conductivity is used in wires and electrical contacts.

- They are primarily used in heat exchangers and also in plumbing systems.

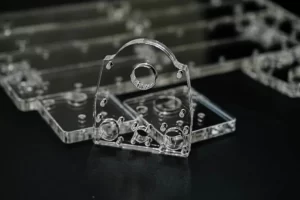

- Clear and hard-wearing, used to create showcases and billboards.

- Applicable to protective covers and other decorative components.

- Thermochromic and optically translucent.

- She was employed in products such as car parts and other robust containers, lenses of spectacles, and safety glasses.

- It is rugged and can also withstand chemical attacks.

- They are used to produce car parts and electronics. Most often used in furniture and covers.

- Chemically resistant and with low friction, it makes seals and gaskets.

- Extensive preparation of non-stick surfaces in many other industries.

Try Prolean Now!

Finishing Options For CNC Drilling

As the machined or deburring

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Powder coating

Powder coating is the electrostatically applying of dry powder to the surface. It produces a thin layer providing excellent resistance to wear, corrosion, and abrasion.

CNC Drilling Applications

Automotive

Prolean employs CNC drilling in automotive manufacturing to create engine parts, chassis components, and fastener holes, guaranteeing that every vehicle is assembled and built to last.

Aerospace

Prolean’s CNC drilling produces accurate holes in aircraft parts for fastening, cable management, and airflow. Drilled materials include aluminum, titanium, and composites, and the drilling is done to specific safety and performance standards.

Electronic

For electronics, our experts make holes in circuit boards and enclosures to mount components, cool devices, and make electrical connections.

Energy

Prolean drills components for turbines, piping, and structural frames in the energy sector are crucial for the effectiveness and reliability of energy supply systems.

CNC Drilling FAQ’s

Technical FAQ’s

What is the best practice for drilling a straight hole?

When preparing to drill a straight rolling, ensure the workpiece is well secured so it does not shift or bend. For high accuracy, the drilling depth should generally not exceed four times the diameter of the drill bit.

Is it possible to thread holes through a drilling operation?

No, drilling alone only smooths the surface of the material, and there are still no threads on it. To make internal threads, one has to use a tapping tool to make threads on the walls of the hole.

What is the maximum depth that CNC drilling can achieve?

The depth that a CNC machine can drill depends on the type of drill and its capability to drill to a certain depth. Typically, a CNC drill can drill to a depth five times the drill bit’s diameter without distorting the hole. Peck drilling methods are generally used for deeper holes. With these more advanced methods, the depth can sometimes reach up to 400 times the diameter of the hole.

General FAQ’s

What is the difference between CNC Drilling and Thread Tapping?

CNC drilling makes holes in the workpiece using drill bits for further processing or joining. Thread tapping, in contrast, aids in making internal threads in these holes by use of a tap tool to use screws or bolts in the construction process.

What are the benefits of using CNC drilling?

CNC drilling is a relatively precise, faster, automatic, and flexible machining process. Therefore, it suits high repeatability and quality requirements across all sectors.

What types of parts can be made using CNC drilling?

CNC drilling can make various parts, from simple plates with a few holes to complex components with intricate drilling patterns. It produces everything from electronic enclosures to automotive parts and aerospace components.

3 Ways to Ensure Perfection

Standards

Metals: ISO-2768 fH (fine)

Plastics: ISO-2768 mK (medium)

Metric threads tolerances: ISO 965-1 standard UN Threads Tolerances: ASME B1.1-2003 standard

Knurling: ISO13444:2012 standard.

Our factory is ISO 9001:2015 certificated

Inspection and Protection

Constant visual inspection conditions

Quantification of cosmetic surface quality

Process requirements

Part cleaning and Protection

Quality Inspection Report

Inspection Confirmation

Dimensional confirmation

Appearance confirmation

Quality documentation

Technology Overview

What is CNC Drilling?

CNC (Computer Numerical Control) Drilling is a widely used subtractive manufacturing technology that involves the use of computers to control machine tools. These machine tools, in the case of CNC drilling, are drills that are used to create holes of different diameters and depths in a variety of materials.

Principle of CNC Drilling

At the core of CNC drilling is a computer-controlled system that directs the drill bit’s movements. The drilling process begins with a digital 3D design of the part, created using CAD (Computer-Aided Design) software. The 3D design is then converted into machine instructions using CAM (Computer-Aided Manufacturing) software. These instructions, or G-codes, control the movement, speed, and positioning of the drill bit.

Advantages of CNC Drilling

CNC Drilling machines can have multiple axes of movement. Most commonly these are 3-axis machines, but there are also 4 and 5-axis machines that offer even more flexibility, allowing the drill bit to approach the workpiece from different angles and in different positions.

One of the key advantages of CNC drilling is its precision. It can achieve very tight tolerances, often as tight as ±0.0005″ (0.0127mm). This high degree of accuracy is consistent across all parts produced, regardless of the production volume.

Another advantage is the ability to drill complex and intricate patterns that would be difficult or impossible to achieve manually. This makes CNC drilling suitable for a wide range of industries, including aerospace, automotive, electronics, medical, and more.

Get Your Parts Made Today

All uploads are secure and confidential.