Chrome plating is a metal finishing technique that can change the appearance of the metal part to improve its aesthetic appeal, durability, and in some cases functionality of components across industries.

In this guide, you’ll learn about the chrome plating process, types of chrome plating available, and materials that can be chrome plated. In the end, you’ll also find tips on maintaining chrome parts.

What Is Chrome Plating?

Chrome plating is an electroplating process that deposits a thin layer of chromium on a surface, part or substrate. Chrome coating serves the primary function of improving the part’s appearance and corrosion resistance. You can find chrome-plated parts for both decorative and functional purposes.

The chrome plating process, also called chrome electroplating, uses a plating solution with chromic acid. It also relies on an electric current that deposits the chromium ions from the anode onto the workpiece, resulting in a durable chrome finish resistant to tarnish.

Types of Chrome Plating

Chrome plating can be categorized into several types of plating depending on performance and aesthetic requirements. Selecting the right plating method is ideal to get the right finish.

Chrome Hard Chrome Plating

Hard chroming part

Hard chrome plating deposits a thick layer of chrome (0.0002” to 0.020”). Hard chroming parts can improve wear resistance and durability. This property makes chroming parts useful in high-stress applications. Hard chrome plating applications include machine parts, tools and pistons.

This type of plating protects the part against corrosion and abrasion. Durable chrome coating can increase the lifespan of metal parts.

Decorative Chrome Plating

Decorative chrome plating focuses on aesthetics and produces a bright chrome finish, usually over a nickel plating layer. The nickel layer serves as an adhesion improver. Decorative chrome plating is commonly used for automobile parts like bumpers, wheels and parts to enhance them visually.

Chrome and nickel mixture ensures a lustrous, durable chrome finish, as the nickel layer ensures a lustrous durable finish while chrome provides the corrosion resistance. It is also used in architecture and fixtures.

Black Chrome Plating

Black chrome plating creates a dark finish. Black chrome plating uses a modified plating solution for a unique, non-reflective finish. This type of chrome is popular for aesthetic purposes. Black chrome plating is widely used in automotive parts and some aerospace parts to reduce glare and reflection.

It helps maintain corrosion resistance, and the thin, dense chrome coating ensures increased durability.

Trivalent vs. Hexavalent Chromium Plating

Traditional chrome plating uses hexavalent chromium baths with chromic acid. These baths have some environmental protection concerns linked with them due to toxicity and are regulated by the Environmental Protection Agency (EPA).

Trivalent chromium baths are safer and use a less toxic plating solution, reducing environmental protection impact. Modern chrome shops use trivalent chrome baths because they are more sustainable.

Materials Suitable for Chrome Plating

Chroming parts can be done on various materials and the choice of metal affects the chrome plating process and the final chrome finish.

Steel and Stainless Steel

Steel and stainless steel parts are commonly used for chrome plating. They have high strength and are compatible with electroplating. For chrome plating stainless steel, nickel plating is used as an intermediate layer, which enhances corrosion resistance and makes for a durable finish.

Aluminum and Copper

Aluminum and copper both can be chrome plated, but require a special step before chroming. Zinc plating and copper plating can create a compatible surface that can act as an adhesion layer for the chrome layer.

Aluminum, specifically, can be anodized before plating to improve chroming results. Copper plating can also help smooth the surface of metals for decorative plating.

Brass and Zinc

Brass and zinc alloys like pot material are used in decorative chrome plating, and a nickel undercoat can prevent corrosion to prolong life.

These metals are commonly used in decorative items and aesthetic components and high-quality chrome can give it a lustrous, shiny silver appearance.

Plastic

You can also chrome plastics, but this requires a coating of nickel or copper to enable electroplating with a thin layer of chromium. This method is commonly used in toys, electronics, and decorative car parts. For injection molded parts, it provides a metallic appearance to non-metal parts.

Try Prolean Now!

What Is The Chrome Plating Process

Chrome and electroplating line

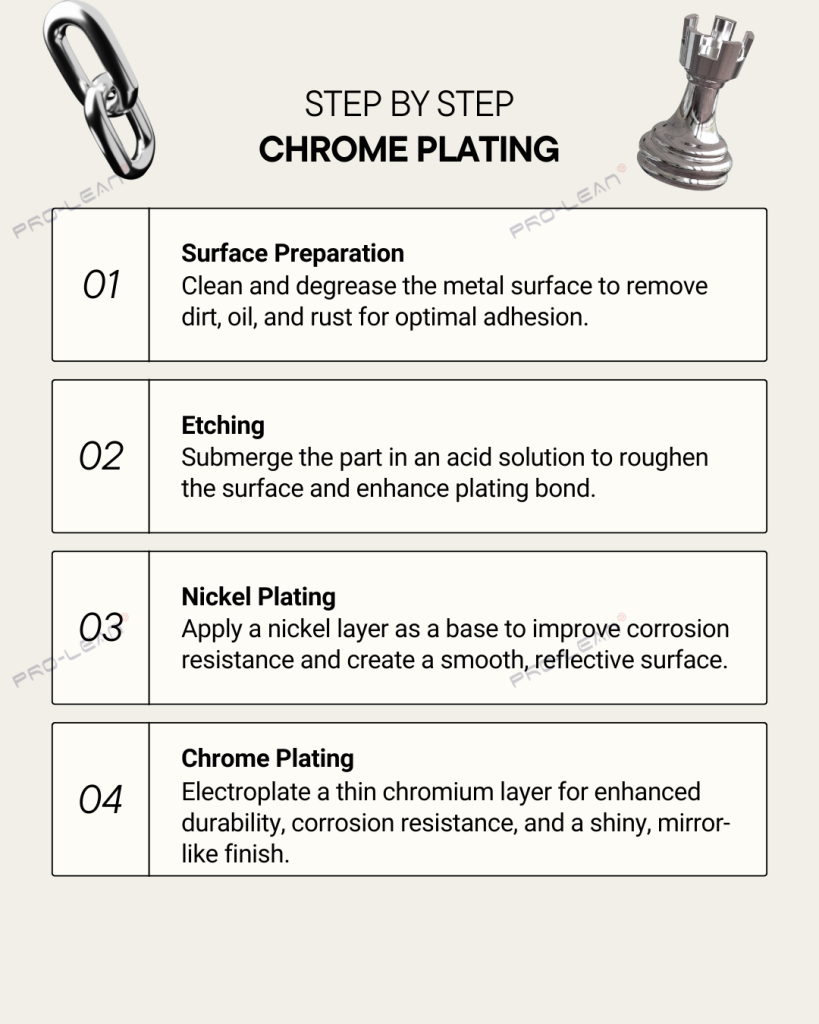

The chrome plating process has a few steps that need to be processed in the right order for a high-quality chrome finish.

Surface Preparation

The first step in chrome plating is removing imperfections on the surface of the part that can cause defects. Cleaning and surface preparation with degreasers gets rid of dirt, grease, and oil. Polishing or buffing, creates a smooth and uniform surface. For old parts, you can use stripping to remove old chrome and nickel layers.

Electroplating

The electroplating procedure requires a plating bath with chromic acid. In electroplating, the workpiece to be coated is the cathode, and a chromium anode is used to deposit chrome ions. Just before chrome depositing, nickel plating or copper plating can be used as an intermediate step before the final chrome layer. This is to enhance corrosion resistance and adhesion.

Plating thickness can be controlled by the duration of submerged part and current intensity.

Finishing

Post-electroplating, the part is rinsed to remove residual plating solution, and sometimes additional polishing or buffing is done to brighten the chrome finish. At this stage, the part has minimal imperfections and an overall smooth surface.

Chrome plating process breakdown

Applications of Chroming Parts

Automotive

Car logo chrome plated

Chrome plating is used to improve the shine, and make automotive parts more lustrous and aesthetic. For example, bumpers, wheels, and motorcycle parts are chrome plated for corrosion resistance and appearance.

Industrial Parts

Hard chrome plating is used for machines, machine components, and tools to improve performance under high wear conditions. For example, you can chrome plate pistons and rollers to enhance the durability of parts.

Aerosapce

Chrome plating of aerospace parts is important for high wear components like landing gears. It helps resist corrosion in extreme environments and keeps the parts functional for a longer period of time. Hard chroming parts are essential for maintaining performance under demanding conditions.

Decorations

Chrome plating enhances the visual appearance of parts, appliances, household items, and fixtures. Decorative chrome plating gives a premium feeling and is used in electronics merely for aesthetics. Another advantage is the ability of chrome plating to resist tarnishing.

Try Prolean Now!

Advantages of Chrome Plating

Improved Corrosion Resistance

Chrome acts as a barrier against rust and has the ability to protect metal parts from environmental damage. This is useful for automotive parts because chrome’s corrosion resistance can ensure reliability.

Wear Resistance

Chrome plated part of a boat wench

Hard chrome plating enhances durability. It can protect moving parts from frictional damage and abrasions. Many high-stress components in machines are chrome-plated for this reason. It makes it cost-effective for industrial parts.

Aesthetics

A bright chrome finish enhances the visual appeal of decorations and car parts. It gives them a premium look, and chroming parts are sought after in consumer products like makeup holders, boxes, and pens.

Ease of Maintenance

Chrome-plated surfaces can be cleaned with mild soap and water. They resist tarnish and rust under normal conditions, but if scratched can lead to rust. It can maintain its finish with minimal effort.

Maintenance For Chrome-Plated Parts

Chrome plated tool kit

Maintaining your chrome parts can prolong their life and keep them functional. Proper care of chrome parts is necessary to avoid damage to the layer.

- Regular Cleaning: Soap and water can clean the chrome surface. Mild soap can break down any dirt and grime buildup.

- Don’t Use Abrasives: Abrasive cleaners and tools can scratch the chrome layer and this can lead to rust, visible marks on the smooth finish or damage.

- Polishing: There are many chrome-specific polishes that you can use to restore the shine. This is especially common for automotive parts and enhances the reflective chrome finish.

Anodizing vs. Chrome Plating

| Chrome Plating | Anodizing | |

| Process | Uses electroplating for chrome layer deposition | Electrochemical process that grows an oxide layer on metals like aluminum. |

| Material | Metals | Limited to metals like aluminum and titanium |

| Appearance | Bright chrome | Matte with pores |

| Corrosion resistance | Excellent with a chrome layer that protects against rust | Oxide layer enhances corrosion resistance |

| Wear Resistance | High wear resistance, specifically for hard chrome plating | Also, good wear resistance |

Chrome Plating For Your Parts

Prolean-Tech provides advanced chroming and surface treatment solutions for a variety of components, parts, and industries as part of custom part manufacturing services.

Our surface finishing lab can improve wear and corrosion resistance, adding tothe performance and appearance of parts.

Reach out today to take advantage of our surface finishing service at lower prices and a completely free quote for your project.

Conclusion

Chrome plating is an important surface finishing technique that offers great aesthetic appeal and a silvery shine that is not found in other plating solutions. From automotive parts to industrial components, chroming enhances functionality and appearance.

Although there are some environmental concerns with chroming parts, methods like trivalent chromium baths follow environmental guidelines, and understanding such details in the chrome plating process balances technical knowledge with sustainable results.

0 Comments