“For most engineers, injection molding and stamping are the most common processes, and little is known about aluminum or aluminum extrusion. However we see a trend that aluminum or aluminum extrusion is increasingly used in various industries, and the use of aluminum extrusion can play an unexpected role in cost reduction and weight reduction.”

In our last blog (Aluminum Extrusion Explained, Pros and Cons) we briefly covered the fundamentals of aluminum extrusion, extrusion methods, material selection, and the advantages and disadvantages of aluminum extrusion. Only when we fully understand the process, tooling, characteristics, and application of aluminum extrusion molding and other related knowledge, we can be able to design aluminum extrusions to ensure high quality and low cost of aluminum extrusions, which is the most critical point for good DFM.

To bring you a more comprehensive understanding of aluminum extrusion molding. This chapter will elaborate on the aluminum extrusion process from three aspects: extrusion aluminum touch tool, process characteristics, and application scenarios.

Aluminum Extrusion Dies

Although product design engineers do not design aluminum extrusion dies, understanding the basic extrusion die structure and the mechanism of how it forms different extrusion profiles can help to reduce die costs and improve extrusion productivity through optimized design when designing extrusions.

What are Aluminum Extrusion Dies

Extrusion dies are essentially thick, circular steel discs containing one or more openings to form the desired profile. They are typically made of H-13 die steel and are heat-treated to withstand the pressure and heat of hot aluminum as it passes through the die.

Aluminum Extrusion Dies

Although aluminum appears to be a very soft metal, it takes a lot of pressure to push a solid aluminum ingot (billet) through a thin, porous aluminum extrusion die to form the desired shape.

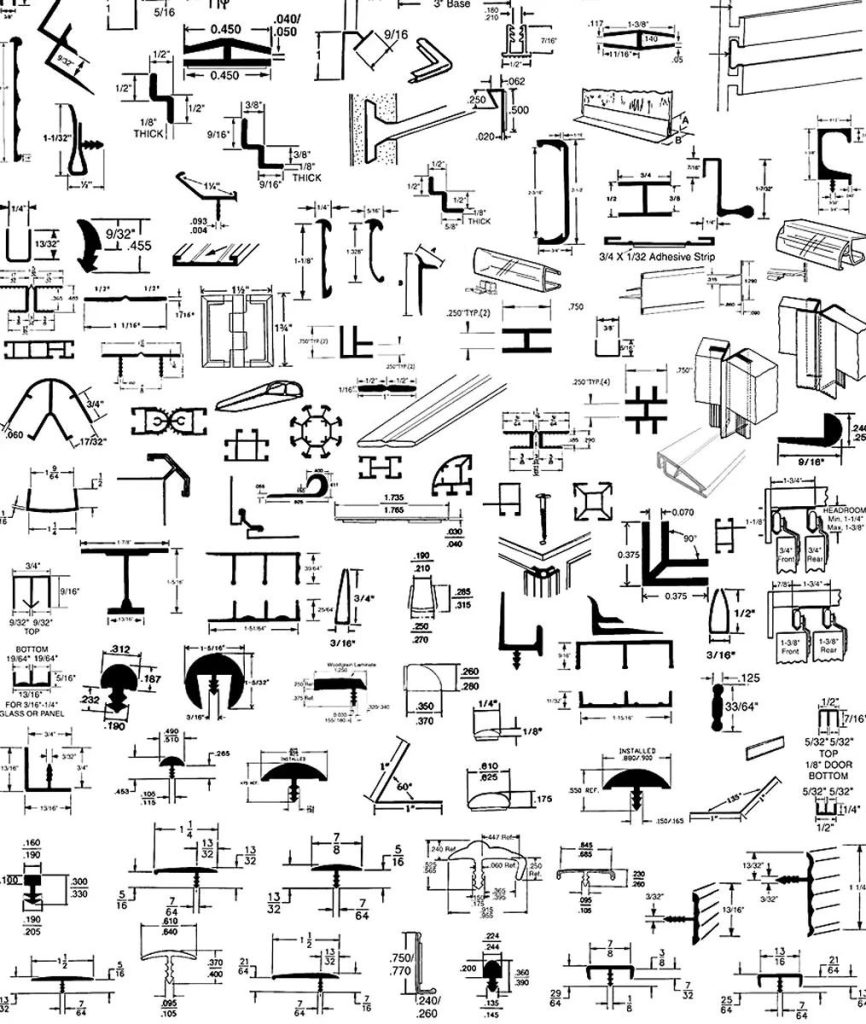

Types of Extrusion Dies

According to the cross-sectional shape of aluminum extrusions, their corresponding dies are divided into three categories: solid dies, semi-hollow dies, and hollow dies. Among them, the hollow die has the most complicated structure, easy to wear and break, and has the highest cost.

Solid Aluminum Extrusion Die

Hollow Aluminum Extrusion Die

Semi-hollow Aluminum Extrusion Die

Extrusion Die Life

Heat buildup and uneven pressures (e.g., thin walls, uneven wall thicknesses, and protruding features) resulting from aluminum extrusion design are the biggest killers of extrusion die life.

Heat and uneven pressures can be controlled by proper die design and extrusion speeds can be reduced to extend die life, but eventually dies must be replaced.

Before designing an aluminum extrusion, the product structural design engineer should understand which design features will most significantly affect tooling costs. Changing the design of the aluminum extrusion cross-section, setting proper tolerances, and selecting the right aluminum alloy material can save the machining cost of the aluminum extrusion die according to the requirements.

Try Prolean Now!

Advantages of the Aluminum Extrusion Process

Long-lasting Durability

Aluminum’s resistance to corrosion, corrosion, and weathering is one of its most significant advantages. Aluminum naturally rusts and resists corrosion without additional treatment. This is due to the presence of a thin, naturally occurring protective film of aluminum oxide on its surface. By anodizing, its corrosion resistance can become even stronger.

Aluminum extrusion parts

For example, in outdoor environments, anodizing can be performed at 25 microns, which enhances both corrosion resistance and surface finish. In addition, aluminum does not require maintenance and can be used without fear of corrosion in most cases.

Lightweight and Strong

Aluminum is more than 33% lighter than steel while retaining most of its strength. The tensile strength range of most aluminum alloys is about 70-700 MPa, while the density is two-thirds smaller than that of steel.

Aluminum extrusion in the body of Audi A8 in blue

Product design engineers do not have to worry about the strength of aluminum extruded parts, and they can be used as structural parts in the construction industry as well as in the automotive industry, making them the best alternative to other metal materials. Aluminum alloys are being used significantly in the automotive industry for lightweight and energy reduction.

Good Thermal Conductivity

Aluminum has extremely similar thermal conductivity to copper, but is much lighter in weight. Aluminum is an excellent thermal conductor, and the contoured design of aluminum extrusion maximizes the surface area for thermal conductivity and the formation of thermal channels. A typical example is a computer CPU cooler, where aluminum is used to carry heat away from the CPU.

Aluminum thermal conductor

Stylish Appearance

Extruded aluminum can be painted, plated, polished, and anodized, which gives engineers a wider range of appearance options than other materials.

Colorful aluminum extrusion parts

Wide range of Applications

Any section shape can be formed by aluminum extrusion, so the application of aluminum extrusion is very wide, engineers can design different sections to meet the requirements of different application environments.

Wide range of applications of aluminum extrusion

Easy Secondary Processing

Aluminum extrusions can be easily formed, cut, drilled, machined, stamped, bent, and welded to suit specific purposes.

Short Cycle Time and Low Cost for Die Processing

Aluminum extrusion has a simple die, a short processing cycle, and a low cost.

Absorption of Impact and Deformation

In construction, aluminum extrusions can resist deformation caused by weather and building movement. In transportation tools, impact energy can be absorbed. Aluminum extrusions maintain strength and flexibility under load and spring back from impact.

Aluminum extrusion is used in automobiles to absorb impact energy

Environmental Protection

Aluminum is an environmentally friendly material and can be easily recycled.

Try Prolean Now!

Application of Aluminum Extrusion Process

Aluminum is the metal of the future; it is not only environmentally friendly, lightweight, naturally corrosion resistant and strong, but also conducts heat and electricity well. The use of aluminum extrusions in the United States has grown for the sixth consecutive year and now represents nearly a quarter (22%) of the total North American aluminum market.

While the construction industry continues to dominate the use of aluminum extrusions, industry use has expanded as more engineers and designers are learning about the almost limitless design possibilities when using aluminum extrusions. Here are the seven industries where aluminum takes center stage:

1. Aviation and aerospace industry

Application in aviation industry

Aluminum has been an important part of the aerospace market from the beginning – the Wright Brothers’ original models used aluminum parts in their engines to reduce weight. Today, aluminum makes up 75-80% of modern aircraft and is often chosen for structures and engines due to its lightweight but durable nature. Aluminum is also one of the main components of many spacecraft.

2. Transportation Industry

In the transportation industry, where specific strength is critical, aluminum extrusions are ideal for engine blocks, transmission cases, panels, roof longitudinal beams and chassis, and vehicle bodies and components for automobiles, ships, trucks, railroads, and subway vehicles.

Application in Transport

The transportation industry is the second largest user of aluminum extrusions, and it is growing. From Ford to Audi to Mercedes-Benz, automotive engineers and designers have been looking for ways to replace steel components with aluminum to improve fuel efficiency and performance. Electric vehicles are also making extensive use of aluminum.

3. Construction industry

Application in the construction industry

Unlike steel, aluminum can be extruded into complex designs and manufactured to meet strict building product specifications, helping to drive its use in many residential and commercial building products. From windows, doors, atriums, and skylights, to ramps, balconies, and various roof designs, architects are turning to aluminum to build green, sustainable buildings that will stand the test of time.

4. Consumer industry

Application in the consumer industry

Since aluminum extrusions were first introduced in washing machines and dryers, it has revolutionized the home appliance market, making air conditioning systems and refrigerators more energy-efficient than ever before. Today, many of our everyday items, including fitness and exercise equipment and furniture, are made from aluminum extrusions.

5. Electronics industry

Application in electronic industry

Aluminum extrusions are used in many electrical and electronic devices. Given their unique electrical and thermal conductivity, custom aluminum extrusions are often used for motor housings, high-heat dissipation heat sinks, and internal frames. In some cases, complete product housings are designed in aluminum, which can be found on many laptops, Apple iPhones and iPads, and high-definition televisions.

6. Lighting industry

Application in the lighting industry

Due to the thermal conductivity of aluminum, engineers can design complete extruded light-emitting diode luminaires that can transfer and dissipate heat for optimal thermal efficiency. In addition, extrusion dies are relatively inexpensive, and aluminum extrusions are easy to cut, shape, bend, process, and anodize or paint, making them ideal for efficient lighting. According to the Aluminum Extrusion Council AEC analysis, “the growth potential for aluminum extrusions for light emitting diode lamps/housings in all market segments is virtually unlimited ……”

7. Solar Energy Industry

Aluminium extrusion in solar panel

When it comes to solar energy, proper installation and mounting of solar panels is critical to quality and performance. As a cost-effective alternative to steel, aluminum extrusions provide the strength needed to resist natural elements (such as snow and wind) without adding weight, making them ideal for roof-mounted panels and building-integrated photovoltaic (BIPV) systems.

Summing Up

Prolean offers a wide range of materials for aluminum extrusion, including metals and plastics. Please see the sample list of materials we use. If you need material that is not listed here, please contact us as we will likely be able to source it for you.

Thank you for sharing this aluminum extrusion information’s. “I’ve been using aluminum extrusions for a few DIY projects, and this article provided some great insights. Do you have any recommendations for surface finishing options that are cheap and effective?

Hi David. For aluminum extrusions, popular surface finishing options include anodizing, powder coating, and painting. Anodizing is especially great for enhancing corrosion resistance and can give a sleek, uniform finish. Powder coating offers a wide range of colors and is highly durable. If you’re looking for something specific, feel free to share, and we can provide tailored solutions for your finishing need.

How does the flexibility of aluminum extrusion contribute to rapid prototyping in industries like consumer goods? Any one with the best answer?