4340 alloy steel machined parts applications and properties

Manufacturers turn to 4340 alloy steel machined parts for high-performance components. This Nickel-chromium-molybdenum alloy steel is very strong, tough, and resistant to fatigue, and is very important as it is one of the very few materials able to withstand extreme stress and wear conditions. For over 20 years, ProLean Tech has been one of the leading producers of alloy steel machined parts to spec. We can provide expert advice on custom CNC machining and what material best fits your needs.

4340 Alloy Steel: Key Characteristics and Composition

Alloy steel 4340 is part of the low-alloy family. It offers a combination of good mechanical characteristics due to the optimal combination of its chemical components. The designation “4340” as per the alloy numbering system assigned by the AISI/SAE corresponds to the predominant alloying elements and the rough carbon content.

Chemical Composition of 4340 Steel

Alloy steel grades differ from one another in how well they perform, and the alloy steel 4340 grade is a good example of a grade with a well-designed chemical composition.

Key Alloying Elements

The elements combined with 4340 steel provide the various properties of the steel. The heat treatment process provides the needed carbon for the strength and toughness of the steel. Toughness is needed especially under impact and at low temperatures, and is provided by the nickel addition.

With this alloy, Silicon (deoxidizer), Chromium (increases corrosion resistance, hardenability, and wear resistance), Molybdenum (high temp strength and low temp brittleness), and Manganese (Deoxidizer, corrosion resistance, and hardening) make the steel better for different applications.

Physical and Mechanical Properties

Having the 4340 steel properties allows for better decision-making by engineers. The material must be versatile and be heat-treated to achieve some specific requirements.

|

Property |

Value (Annealed |

Value (Quenched and Tempered) |

|

Tensile strength |

108,000 psi |

230,000-260,000 psi |

|

Yield Strength |

95,000 psi |

200-230,000 psi |

|

Elongation |

22% |

10-12% |

|

Hardness |

217 HB |

50-55 HRC |

|

Density |

0.283 lb/in3 |

0.283 lb/in3 |

Compare 4340 and 4140 for Machined Parts

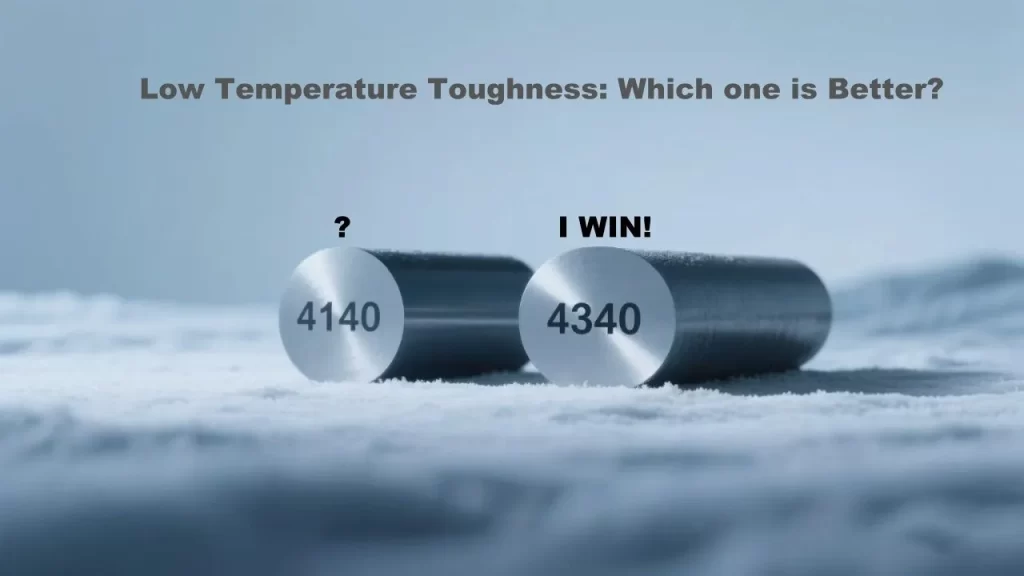

4140 vs 4340 alloy steel machined parts

Choosing between 4140 and 4340 steel grades can affect the performance of components and the cost of manufacturing. While both are in the chromium molybdenum family, the differences in composition lead to distinguishing factors.

Differences in Composition

4140 contains less nickel than 4340, resulting in loss of certain toughness and hardenability characteristics. Because 4140 is more economical, its performance under extreme conditions is limited due to nickel deficiency. Impact resistance and low temperature toughness are better with 4340 due to its greater nickel content.

When To Choose 4340

When extreme toughness under high stress, and max impact resistance is needed, 4340 is the best choice. It is used in components that are subject to high stress concentrations or repeated shock loads. 4340 is usable in low-temperature environments, because failure of the material can be a severe issue. The grade of strength is subject to the reliability and safety of the components in aerospace and defense. It is also needed in heavy-duty crankshafts and parts of the transmission that can withstand constant vibration and repeated shock loads.

When to Choose 4140

Choose 4140 steel when extreme toughness is not important and balanced strength and cost are the main focus. It is possible to create general-purpose fixtures and tooling at a low cost with consistent quality and good machinability. Reliable results with low material and manufacturing cost is why this steel is used in standard auto industry parts.

Machinability Consideration

Both 4340 and 4140 steels can be easily machined when in the annealed state. 4340 needs more consideration during CNC machining metal parts, though, due to its higher alloying elements, leading to increased tool wear. This means specific conditions and tool selections must be made.

Grades of Alloy Steel

Understanding the alloy steel grades list helps manufacturers understand which material is best for theirrequirements. The AISI/SAE system covers thousands of steel grades and classifies them based on primary alloying elements and the intended purpose.

High-Strength Alloy Grades

In the category of high-performance steels, 4340 is up against several other premium grades. Materials such as 4330V and D6AC, which offer special properties for extreme applications at a cost that is often significantly higher than 4340 standard steel, are available.

Best Steel for CNC Machining: 4340 excels in CNC operations

When selecting the best steel for machining, it is important to balance mechanical properties, machinability ratings, and final component requirements. Although 4340 alloy does not top the charts for machinability like other grades of free-machining steel, its combination of workability and performance makes it highly desired for precision applications.

Machinability Characteristics

The machinability of 4340 steel is typically rated between 45-50%, compared to steels that are rated 100% for free-machining. This rating is moderate due to the high alloy content of this material and its strength. It requires proper machining but rewards manufacturers with superior component performance.

The annealed condition (217HB maximum) allows for efficient material removal using standard tooling. Pre-hardened conditions can increase tool wear, but allow manufacturers to produce components with a near-net shape that require minimal finishing.

Optimal Cutting Parameters

Cutting speeds, feed rates, and tool geometry are all important factors in the successful machining of alloy 4340 steel components. When operators use modern CNC equipment and the appropriate tooling, they can achieve excellent results.

Surface Finishing Capabilities

ProLean Tech’s advanced steel CNC machining capabilities can produce 4340 components, with finishes ranging between 125 Ra and 16 Ra for precision-ground surfaces. The versatility of the machine allows manufacturers to balance functional and cost requirements.

4340 Steel Castings vs. Wrought Forms

4340 alloy steel castings

4340 steel casting is an excellent option for large and complex components. Understanding the trade-offs between wrought and cast forms helps guide optimal manufacturing processes.

Cast 4340 Steel Properties

Cast 4340 is slightly less mechanically efficient than wrought because of the solidification process. The casting process may introduce variations in porosity or grain structure. Under the same heat treatment conditions, forged/rolled 4340 generally exhibits better strength, fatigue performance, and fracture toughness than the as-cast state. Casting can reduce the amount of material removed from the blank.

When to Use Castings

Castings are often justified due to complex internal passages and external al-contours. Casting can be used for large components with dimensions that are larger than the bar stock standard. This eliminates the requirement for extensive welding and fabricating.

Ideal Casting Applications

Casting is an excellent option for valves that have complex internal flow paths. Casting is a good option for large housings and frames because they are rigid and can support a lot of weight. By using integrated brackets, mounting assemblies, and other components, you can reduce the number of pieces that need to be assembled while improving structural stability. Casting is also used for prototypes, as it allows precise evaluation of complex geometries before full-scale production.

The Wrought Materials Advantage

The 4340 bar stock is forged and rolled to provide maximum properties and consistency of quality across its entire cross-section. Wrought forms are best used for structural components that need to be high-cycle fatigued or critical structural elements.

Try Prolean Now!

Custom CNC Machining for 4340 Components

CNC-machined parts of 4340 steel alloy

CNC machining turns raw alloy 4340 into custom-engineered components that satisfy different tolerances for dimensions and surface finishes. Advanced machining technology makes possible to quickly and cost-effectively manufacture prototypes and mass quantities.

Advanced Machining Technologies

CNC 5-axis machining centers, turning-milling combo machines, and high-precision grinders all help to manufacture 4340 alloy steel components. Multi-axis machining improves accuracy and reduces setup time. Advanced machining tools create complex details and fine features that typical machining methods cannot produce.

Swiss-type CNC machines are the industry standard for producing small parts with high tolerances and optimal surface finishes. These machines can achieve the least tolerances of 0.0005 inches for shaft-type parts and can achieve this at great production rates.

Heat Treatment

Treating 4340 Steel with heat makes it tougher, more fatigue resistant, and turns it into a high-strength material. Each heat treatment step must be performed to relieve stresses and fatigue to better prepare the steel for service conditions. Normalizing is first done at high temperatures, then cooled with air to refine the microstructure. The next step is to harden the material by heating it to the same temperature as the last step, then quickly quenching it in oil.

Tempering modifies how hard the material is over a range of applications. Stress relief at mid-high temperatures aids in maintaining dimensional stability and reduces the internal stress by meshing or forming the material.

Management of Quality

Using coordinate measuring machines, alloy steel 4340 parts will be inspected, and hardness and non-destructive tests will be performed to check the specs. ProLean Tech employs a Material Cert, Dimensional, and Surface Finish Quality check to provide a Surface Finish Quality Cert.

Uses of 4340 Alloy Steel Machining Parts

Uses of 4340 alloy steel machined parts

The 4340 steel is a high-reliability alloy that can fail catastrophically. Engineers recommend the use of this high-grade alloy in situations where they require the highest level of reliability under extreme operating conditions that demand maximum safety.

Aerospace Defense

Landing gear components, structural fittings, and arresting hooks all require the high absolute strength, toughness, and fatigue resistance of 4340 alloy steel. In order to meet the needs of applications requiring component integrity, 4340 alloy steel machined parts are in high demand in the aerospace industry.

The military applications of gun barrel els and armor-piercing projectiles, as well as vehicle axles, are high shock load and hard conditions applications. To speed up design approvals, the long-term performance history and qualification data can be used.

Automotive

It is used in high-performance automotive parts such as connecting rods, engine cylindrical shafts, and crankshafts. These are subjected to extreme loads on a regular basis. Professional racing teams are aware of the importance of 4340-specified, powertrain parts that directly impact performance.

It is used to manufacture the axle shafts and off- road suspension of rock crawlers. This material can absorb energy without breaking, making it suitable for extreme off-road driving. The 4340 material is able to absorb energy without breaking the h ence, making it suitable for off-road use.

Industrial Machinery

The 4340 is used in large machinery for gears, shafts, and structural components. These include mining equipment and construction machinery, as well as industrial presses. This high-hardenability material allows for the uniform hardening of large sections of material.

Oil and gas drilling uses down hole tool like tool joints, drill collars, and other such tools. The components must be able to withstand corrosion and be structurally sound.

Power Generation

These parts can be used to make gearboxes for wind turbines and shafts for hydroelectric turbines. These components can last for decades. This material is highly fatigue resistant, allowing for long-term performance in applications where loads are subjected to millions of load cycles.

Try Prolean Now!

Specifications for 4340 Machined Parts

A successful component procurement should include the transfer of quality and material standards. You can meet your short-term production needs by collaborating with experienced producers of alloy steel 4340 machined products.

Requirements for Material Certification

It is a requirement that the aerospace and defence industry has full material traceability. The aerospace and defense industries require certified mill tests in order to report chemical and mechanical compositions.

Considerations for Design

Designers must consider the hardenability of components when determining their thickness and other geometrical properties. Oil quenching can increase the final hardness, which can optimize the geometry of a part to improve efficiency and performance. A low-alloy and not epoxy, such as 4340, can’t be treated in a general way. To reduce fatigue cracks, large fillet radius and smooth transitions are used.

Lead Times and Pricing

Standard 4340 bar stock is available when complex heat treatment cycles are not required. This can reduce lead time for CNC-machining metal components. Custom heat treatment specifications may extend production schedules due to surface treatments and tight tolerances. However, components will still meet their application’s needs.

Conclusion

Alloy-steel machined components manufactured from 4340 are ideal for applications requiring maximum strength, toughness, and reliability under extreme operating conditions. The material’s balanced composition provides excellent mechanical properties that allow engineers to design lighter, stronger components in harsh environments.

ProLean Tech’s expertise in precision machining and heat treatment of 4340 alloy steel ensures that your critical components will be manufactured to the highest standard while maintaining a competitive lead time and price. Our integrated manufacturing capabilities ensure the quality and consistency you need for your projects, from initial material selection through to final inspection.

Are you ready for your design ideas to be turned into precision-engineered components? Contact ProLean Tech today to discuss your project requirements, explore material optimization options, and receive a quote for custom CNC machining of metal parts.

0 Comments