Machining Guide for 7075 Aluminium

The 7075 aluminum is a sweet spot in the manufacturing world because of its high strength, which is accompanied by its superior machinability. 7075 aluminum is good in the aerospace market, the automotive market, and also in high-performance applications. It is a high-strength alloy, which is of equal yield strength to certain steel varieties. It has the lightweight property and excellent chip-forming quality of aluminum. The optimization of this material can be achieved through the knowledge of optimization of cutting parameters, selection of tooling, and fixturing.

ProLean Tech is one of the leading companies offering aluminum CNC machining, and it has extensive experience in using 7075 aluminum alloys, among other high-performance aluminum alloys. Components are always given high precision by our CNC and well-trained machinists. The custom aluminum machining that we offer as standard will provide what should be done in time and at the optimum quality, whether it is the development of a prototype or mass production.

Why 7075 Aluminum Is Ideal for CNC Machining

Aluminium 7075 has an exceptional strength-to-weight ratio. It is best to use it in applications where lightweight and high-performance parts are needed. It is high machinability that’s why it can easily be used to create complex shapes and geometries. Aluminium has high fatigue resistance and is perfect for weight-critical industries like aerospace.

7075 Aluminum material properties & Chemical Composition

7075 aluminum material propertiesare due to its chemical composition. This is a zinc alloy that has a special position in the family of alloys. It can compete with steel in terms of strength and still has the advantage of processing aluminum.

Chemical Composition

The major alloy of the 7075 is zinc (5.1-6.1%), as it also contains copper (1.2-2.0), magnesium (2.1-2.9), and chromium (0.18%-0.28) that enhance the strengthening property of the alloy. Precipitation-hardening heat treatment can be used in this composition, and it is much stronger than other types of aluminum.

The most common temper, T6, which is used in machining application is attained to 83,000 PSI ultimate tensile strength and 73,000 PSI. The values are the same as those of medium carbon steels, and aluminum has retained its density of 2.81 g/cm3.

The level of iron is limited to 0.50% so that it can be machined best. Silicon level is maintained at a low level (0.40%) to guarantee optimum machinability. These regulated levels of impurities would help to form the good surfaces that are attained whenever 7075 aluminum is machined using the appropriate techniques.

Mechanical Properties

Grade 7075 is better in terms of aluminium strength than any other grade. Its high tensile, high fatigue resistance, and good stress cracking resistance make it the most suitable to use as a structural component when it is subjected to extreme strain.

T73 temper is used in the application where durability and thick sections are needed. It has superior stress corrosion cracking, although it has a lower strength (78000 PSI ultimate tensile). Your application will influence the type of material you will use and the heat treatment specification.

T6 vs T73 temper

T6 and T73 are the variants of 7075 Aluminum. They share the chemical composition but develop different physical properties as they are processed by different methods.

7075-T6 Aluminum temper is obtained by heat treating the metal. It is artificially overaged to get the best required mechanical properties. 7075-T73 is the aluminum temper obtained after heat treatment of the metal. It is stabilized by artificial overaging to get maximum stress corrosion resistance.

Machinability Characteristics of 7075 Aluminum

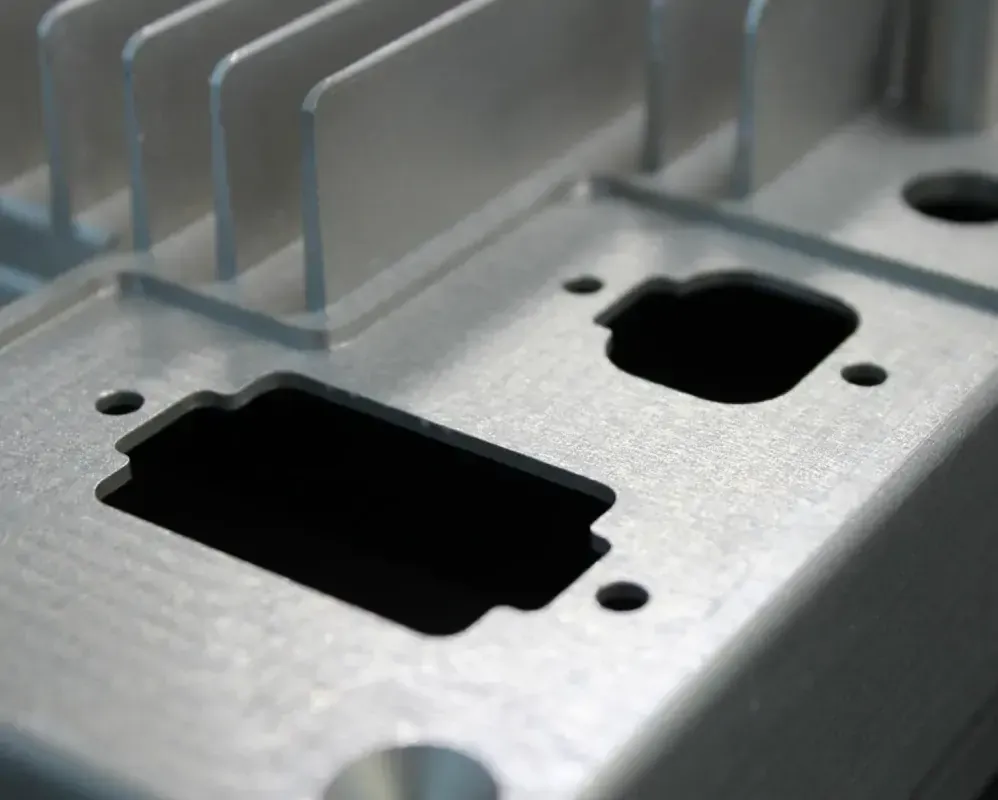

CNC machining on Aluminum 7075

The 7075 aluminum machinability is, in fact, good in offering prompt metal removal and a clean finish. The chip and features of the material and chip determine the optimal environment of CNC operations with high productivity.

Machinability Rating and Chip Formation

7075 aluminum machinability is 70 percent relative to the free-machining brass. This is greater than most of the steels and alloys of Aluminium. Using proper parameters through proper parameter control can be used to achieve higher cutting speeds, longer tool life, and a cleaner surface. This will result in enhanced production with a lessening of the cycle times and maintaining a constant cutting.

After turning and milling, the alloy provides short and clean chips. This reduces the possibilities of rewelding and removes a stringy buildup of chips. A simple system is used in chip handling, and high-pressure coolant is used to improve chip evacuation. Carbide tools (or sharp PCD) are recommended for cutting the built-up edge. T6 tempering is a brittle material when compared to annealing.

Built-up edge behavior

Aluminum 7075 is very prone to built-up edge formation. It is due to high feed rates and somewhat low or moderate cutting speed. Built-up edges affect the finish quality of products and the rake angle of the cutting tool. Temper condition also affects the formation of edges. The harder the temper is, the fewer edges will be formed, and vice versa.

Comparison with other aluminum alloys

7075 aluminium machinability is good, but we can add it at “B” scale when compared with 6061 aluminum alloy. 6061 is easier to machine, needs less power, and provides smooth finishes, while 7075 requires more power due to its slightly higher hardness than 6061.

CNC Cutting Parameters for 7075 Aluminum

High-Speed Machining

The HSM strategies benefit from the fact that 7075 has an outstanding machinability to give good material removal rates. One can make applications with complex features and high-quality surface finishes using aluminum precision machining tools of small diameter and spindle speeds of over 15,000 RPM.

The trochoidal path also makes the load on the chip constant, as well as the radial contact small. This enables large feed rates to be used in deep cuts, with cutters not being overworked. The process has increased the removal of metals by 300-500 percent as compared to conventional side milling, and the tool life is also increased due to the reduced cutting forces and heat generation.

The further enhancement of productivity comes in the aspect of adaptive clearing strategies, which automatically feed rate is also increased or decreased as the material is engaged. These intelligent toolpaths maintain a constant spindle load without tool overloads that are caused by conventional programming.

The Speeds and Feeds

Aluminum 7075 Parts

When machining 7075 Aluminum, maximize productivity by maximizing the relationship between feed rate, cutting speed, and depth of cut. Due to its superior machinability, the material is machinable with machining parameters that would otherwise ruin tooling.

These parameters will provide a good starting point by which adjustments can be made according to the capabilities of the machine, the set-up of the workpiece, and the desired surface finish. The current high-speed machines can access these upper limits with the appropriate tooling and workholding.

Trochoidal & adaptive clearing

Trochoidal and adaptive clearing are effective methods for roughing aluminum. It is preferred due to its high ability to manage heat and control cutting force; it also has improved chip evacuation compared to conventional methods.

Comparing 7075 Aluminum to Other Materials

By comparing 7075 to other alternatives, engineers are able to make better choices in the selection of the material to use in a certain application. This is the only alloy that has a balance of strength, weight, and machinability.

7075 Billet Aluminum vs 4140 Steel

When comparing 7075 billet aluminum vs 4140 steel, some interesting trade-offs are evidenced. The quenched-and-tempered 4140 steel has a tensile strength in the range of 90 – 150 ksi, although it is almost three times heavier per unit volum situation where the strength-to-weight ratio is a critical parameter, as is the case in aerospace and racing, 7075 is better. When a part is to be used at the same stress levels, it has a weight of about 60 percent of that of a part that is to be made of 4140 steel. This is on the assumption that design modifications are done to take into consideration the fact that aluminum is less rigid.

7075 vs 6061 vs 2024 vs 7050

In machining 7075, it needs to be compared with the other aluminum grades in terms of performance. This is an aerospace and high-performance alloy. Substitutes are 6061 aluminum, 2024, and 7050.

Most commonly used aluminum grades for machining:

- 6061-T6: Weaker (45, 000 PSI max) yet better for welding and cheaper.

- 2024-T3: Same strength (70,000 PSI maximum) but with better fatigue resistance. The aircraft skins are common, and machines find it more challenging to machine them.

- 7050-T7451: Stronger and better stress corrosion resistance. A more costly, but preferably thicker plate option.

- 7075-T6 Industry standard of high-stress components; best combination of strength, machinability, and availability.

The machinability of the 7075 aluminum is better compared to that of the 2024, and is less inclined to form a built-up edge, and has good chip formation. Designs of components can be made lighter because of the increased strength of 7075 as compared to 6061. This counterbalances its marginally high cost of materials in performance-critical applications.

Try Prolean Now!

Selecting the Right Tool for Aluminum Machining

Custom Aluminum 7075 Machining

When working with 7075, the right tool will maximize productivity and surface finish. Material characteristics require different tool geometries and coatings than those used for steels or other metals.

Carbide Tool Geometries for 7075

Carbide tools have been the most popular option for aluminum machining. They provide excellent wear resistance and the rigidity needed to maintain dimensional accuracy at high rates. Performance is influenced by the geometry of the tool. Geometries designed specifically for aluminum outperform designs that are general-purpose.

Positive rake angles of 10-15 degrees can reduce power consumption and cutting forces while improving surface finish. They are more effective on aluminum due to its soft matrix. However, they would chip immediately in harder materials.

The number of flutes has an impact on the rate at which chips are evacuated and the feed rate. Two-flute and three-flute designs are best for roughing passes that require deep cuts. In finishing passes, four-flute and five-flute cutters offer higher table feed rates. Variable helices and pitches improve the surface quality for aluminum precision machining.

PCD Tooling for Production Runs

Tooling is a great choice for machining aluminum with polycrystalline diamond. PCD can improve lifespan by several times to an order of magnitude compared to cemented carbide (typically 5–20×, depending on operating conditions)

Diamonds have an extremely low coefficient of friction and are very hard. Diamonds can cut aluminum without wearing out. The cutting edges remain sharp, so that the surfaces are consistent throughout long production runs. This feature is particularly useful in aerospace applications where dimensional consistency is critical for large lots of parts.

PCD is the most suitable finishing material when high-quality surfaces must be achieved. The material is capable of achieving 8-16 Ra surfaces when speeds and feeds are optimized. It is possible to reduce manufacturing costs by eliminating secondary grinding and polishing processes.

Coolant and Lubricant Strategies

Aluminum 7075 Machined Parts

When machining 7075 Aluminum, adequate use of the coolant enhances the life of the tool, surface quality, and dimensional accuracy. Even though the high thermal conductivity ofinum will decrease, the cooling needs required, relative to titanium or steel, the choice of coolant and the method of its delivery still matter.

Coolant types and concentrations

These coolants are developed using water-soluble synthetics and semi-synthetics, which are aluminum-specific. These coolants have a combination effect of both cooling and lubrication, which avoids the staining of aluminum or corrosion.

The suggested ratio to machine 7075 aluminum is 5-8 percent, as opposed to the normal 8-12 percent required to machine steel. Lower levels offer sufficient cooling and lubrication, and minimise the quantity of residue on machine parts and workpieces. Over this level of concentrations may result in white deposits that must be removed from aluminum surfaces.

Coolant pH must be maintained at 8.5-9.5 in order to avoid the corrosion of aluminum. Regular monitoring and adjustment of pH, concentration, and bacterial contamination will increase coolant life, consistency of machining, and increase the life of the coolant. The tramp oil removal system helps to eliminate contamination of the oil cutting that reduces the performance of the coolant.

pH and contamination control

Naturally, aluminum forms an oxide layer on its surface. It offers resistance to contaminants and corrosion. The optimal pH level is between 7 and 8. At this neutral pH, aluminum remains in optimum condition against severe contaminants such as chlorides.

Considerations for Workholding and Fixturing

Aluminum 7075 Bulk Machined Parts

Workholding must be used properly in machining 7075 aluminum, especially machining thin-walled components or geometries with complicated shapes in which cutting forces may cause distortion or deflection. It is also easy to bend aluminum components when they are under a load, and this is because the material has a low modulus of elasticity as compared to steel.

Distribution of thin-walled parts

One of the issues that can be linked to the fixturing of thin-walled aerospace parts is that the internal stress will be displaced and distorted during machining due to material removal. Using a symmetrical machining sequence and cutting the material on the other side is not that difficult.

Vacuum fixtures or low-melting-point wax can support thin walls without using much force. Prior heat treatment of the final machined parts may increase the dimensional stability of significant parts through stress relief. It is spread by means of soft jaws in order to fit the geometry of the part with the added hydraulic or pneumatic clamping to eradicate local deformation, as well as spreading the force evenly.

Fixture Design for High Speed Operations

Fixtures must be able to withstand the high-speed cutting forces and centrifugal forces generated by high-speed machining. Fixtures designed for aluminum CNC machining with elevated speeds must be more rigid than those designed using conventional parameters.

Toe clamps or strap clamps must engage the workpieces near the cutting zone to minimize the moment arm, which allows the part to deflect. Pull-down forces tend to be more effective than pushing-down designs because they do not create the lifting moments that side clamps may generate when under heavy cutting loads.

Try Prolean Now!

Requirement to Achieve Aeronautical-grade Surface Finishes

Aerospace applications often specify surface finishes as fine as 32 Ra, and critical sealing surfaces may require 16 Ra. With the right tooling and parameters, it is possible to do machining of 7075 aluminum according to these exacting specifications.

The machining process produces surfaces with a Ra of 16-32 when using sharp carbide or tooling at high speeds (2,500-4000SFM) and fine feeds (0.04 to 0.006 IPT). When using wiper inserts, you can achieve even finer surfaces. This is done by doubling the number of cutting edges that are in contact with the workpiece at each rotation.

Precision 7075 Aluminum CNC Machining at ProLean Tech

ProLean Tech is one of the leading manufacturers of custom metal parts and CNC machining. Our experienced machinists have decades of experience in customized precision 7075 Aluminum. We know all the ins and outs of working with aluminum alloys. At ProLean Tech, we value your time, money, and goals. We become your partner by providing you best quality and smoothly finished parts so that you can achieve your desired results.

Conclusion:

Understanding the process of machining 7075 aluminum is important. It’s also necessary to apply established methods in order to optimize the parameters, regulate processes, and select the right tools. This high-strength alloy of aluminum has excellent machinability, allowing for high rates of material removal and better surfaces and appropriate execution. It is therefore the preferred material for aerospace structural components and high-performance automobile components. Precision machine components are also made from this alloy.

This guide explains how to achieve consistent results using 7075 components. ProLean Tech has decades of experience in precision aluminum machining. This is applied to each project. We have a thorough understanding of the challenges that high-strength aluminum alloys present and how to overcome them. Our skills and expertise can meet your needs, whether you require prototype development or production machining. Get a quote by contacting us.

0 Comments