Machining Polyurethane Plastic

Polyurethane can be thermoplastic or thermoset, but in machining, thermoset polyurethane is used. This material is known for excellent mechanical properties, chemical inertness, thermal stability, and electrical insulation.

Manufacturers use cast polyurethane workpieces and convert them into functional parts and products using milling, turning, drilling, and other machining processes. Based on the polyurethane grade and machinability, you need to apply the right machining parameters and appropriate cutting tools.

The upcoming sections will elaborate on the properties of polyurethane, plastic CNC machining types for polyurethane, machining challenges & considerations, and industrial applications of polyurethane parts.

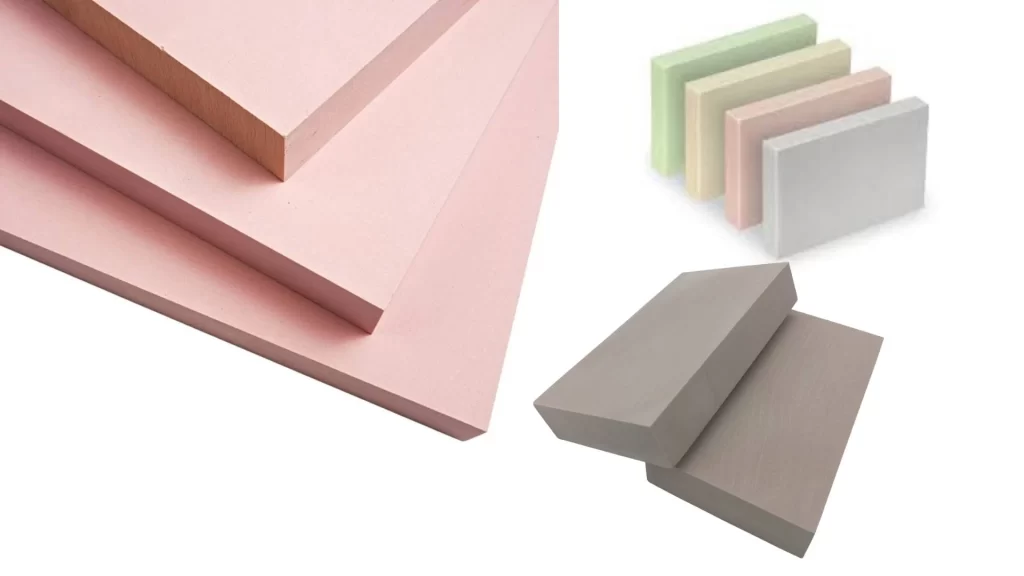

Polyurethane Material and Its Properties

Polyurethane material

Polyurethane is a synthetic polymer made with a combination of diisocyanates and polyols, along with secondary additives. So, internally, PU involves –NH–CO–O– linkages. Although it is available in different forms, rigid polyurethane is preferred for machining purposes.

Cast thermoset polyurethanes with a hardness higher than 60-70 A shore are excellent choices for milling, turning, drilling, and other machining operations. Next, how is thermoset polyurethane made? Open mold casting and reaction injection molding are two main methods for making polyurethane.

In casting, a reactive mixture of polyol, isocyanate, catalysts, and additives is poured into an open mold for shaping, followed by the curing process. On the other hand, reaction injection molding involves two separate supplies mixing in a head and injecting into a mold.

Properties of Polyurethane

- Thermal Stability: Although PU cannot withstand high temperatures, it retains its properties intact in the presence of moderate heat.

- Abrasion Resistance: Polyurethane offers higher wear resistance than regular plastics, enabling it to perform effectively in abrasive conditions.

- Chemical Neutrality: This material does not react with most acids, alkalis, oils, and solvents.

- Mechanical Strength: Polyurethane is a high-strength material that can withstand heavy loads without cracking or failure.

- Properties Customization: By altering the mixing composition and type of additives, polyurethane can be tailored to achieve a specific hardness level and other desired mechanical properties.

Different Polyurethane Machining Processes

Milling rigid PU

Although grinding, sawing, and other machining processes can be carried out with flexible PU, for milling, turning, and drilling, you need PU with a hardness of more than 70 shore A. Otherwise, liquid nitrogen is used to increase hardness before machining. Furthermore, each of these machining processes involves corresponding tooling and machine setup.

Let’s briefly elaborate on Polyurethane milling, turning, drilling, and grinding processes.

Polyurethane Milling

Plastic parts CNC milling is ideal for polyurethane profiling, contouring, and adding complex features. PU harder than 80A shore is recommended for milling operations.

- Tooling: HSS/carbide tooling, sharp double flute end mills, and single-point fly cutters are recommended.

- Feed & Speed: 1000–1300 RPM/0.38–0.51 mm/tooth

Polyurethane Turning

It is used to shape symmetrical parts and features on a cylindrical surface through a stationary cutter and a rotating polyurethane material.

- Tooling: Carbide/HSS tools, high clearance & rake angle

- Feed & Speed: 0.10–0.20 mm/rev and 600–1000 rpm

Polyurethane Drilling

Holes of various sizes and depths can be created in polyurethane material using sharp spiral drills. To prevent chip clogging during polyurethane drilling, adjust the drill point angle according to the work thickness (90–135 °).

- Tooling: Spiral drills with sharp edges

- Feed & Speed: 0.10–0.15 mm/rev and 600–1,000 rpm

Polyurethane Grinding

Grinding can be done in a specialized grinder or CNC lathe with a grinder tool post. The process involves rotating the abrasive wheel, which removes material from the work in a minor amount, refines the surface, and corrects tolerances.

- Tooling: Abrasive wheel with 20–80 grit, based on the hardness of polyurethane

- Feed & Speed: 0.125-0.127 mm/rev, and <150 rpm

What Are the Polyurethane Grades for Tooling?

Polyurethane material is widely popular for tooling in machining, molding, forming, and industrial factories. It can be found in various forms, including grip parts, press tools, punch pads, and vacuum forming molds, among others.

Different polyurethane grades with varying hardness levels are used for tooling, including soft, medium-hard, hard, and rigid-hard polyurethanes.

Soft Elastomeric PU

PU materials with a hardness lower than 50 A shore are classified as soft elastomers. They provide a balance of toughness, tensile strength, and flexibility, suitable holding fixtures, molds, and pads that require slight stretching,

Medium Hardness PU

If polyurethanes have a hardness between ~60–80 Shore A, they are considered medium-hard PU. They offer improved strength without losing significant flexibility, higher load handling capacity, and good machinability. Consequently, they can be machined to create molds, fixtures, and other components.

Hard Elastomeric PU

Polyurethanes with hardness ~ 80–95 Shore A (sometimes only up to 90 Shore) are considered as hard elastomeric PU. They are known for high-tear strength, abrasion resistance, and durability under repetitive loads. Some typical tooling applications include sheet metal forming pads, dies, patterns, and soft-form fixtures. These are also common in urethane tooling for appliance manufacturing.

Rigid Hard Elastomeric PU

The hardness of rigid polyurethane ranges from 70 to 80 Shore D. It is known for structural rigidity, toughness, and high compressive strength, low flexibility, and can be machined with tight precision. Some application examples related to tooling are vacuum molds, master patterns, thermoforming molds, and stamping die prototyping.

Try Prolean Now!

Considerations of Machining Polyurethane

Polyurethane machining

To prevent machining defects and workpiece failure, you must consider the factors like elastic recovery, work clamping, cooling & lubrication

1. Consider the Elasticity of Polyurethane

Polyurethane has a relatively higher elasticity, which requires more machining clearance to overcome elastic recovery. So, the dimensional deviations can be avoided.

Insufficient clearances cause excessive friction on the machining interface, resulting in heat buildup and inaccuracies.

2. Firmly Clamp the Polyurethane Workpiece

High clamping forces cause machining errors and can distort the material. Therefore, firmly secure the polyurethane work; just enough to avoid any vibration or restrict movement while machining.

3. Right Cutting Tool Material

Check the hardness of the polyurethane you are using for machining, and choose the tool material accordingly. Typically, High Speed Steel (HSS) and Carbide tools are used as they help to prevent gumming.

4. Use Coolant and Lubrication

Excessive heat during the machining of polyurethane can cause dimensional distortion and material damage. Therefore, use micro-mist coolant with suitable lubrication. It facilitates the efficient heat dissipation from the machining interface.

5. Optimize Machining Speed and Feed

Since Polyurethane starts to decompose above 175 °C, the feed rate and speed must be chosen carefully. High feed or speed causes high friction & heat accumulation. You can also perform the trial runs before starting the actual production.

Try Prolean Now!

Industrial Applications of Polyurethane CNC Machining

Polyurethane applications

Machined polyurethane parts are used across multiple industries, including automotive, medical, industrial machinery, tooling, manufacturing, and consumer goods.

In the automotive industry, its high strength, lightweight nature, impact resistance, and chemical neutrality provide benefits in terms of performance and durability. The industrial machinery industry utilizes PU machining parts for their load-bearing and shock-absorbing capabilities. Similarly, other industries also benefit from custom polyurethane machining.

Next, let’s look at the table below for application examples:

|

Industry |

Application Examples |

|

Automotive |

Suspension bushings, precision seals, gaskets, protective covers |

|

Medical |

Ergonomic handles, cushioning pads, device housings, Soft-touch grips |

|

Industrial Machinery |

Conveyor rollers, wear pads, guide wheels, pump liners, bushings |

|

Tooling |

CNC tooling fixtures, forming surfaces, vacuum casting molds, and workholding pads |

|

Manufacturing |

Custom rollers, drive components, seals, gaskets, pressure pads, protective machine liners |

|

Consumer Goods |

Sports equipment parts, protective cases, and custom accessories. |

Read More: Thermoplastics CNC Machining

Summing Up

Polyurethane is a valuable machining plastic due to its wide range of mechanical properties, durability, chemical resistance, and load-bearing capacity, and can be machined into complex parts & products. Several types/grades of polyurethane are available for machining, having different hardness levels (70 A shore).

You must consider the elasticity, cutting tool material, feed rate, speed, and other parameters to prevent heat buildup, gumming, and other types of defects. If you are looking for defect-free polyurethane parts tailored to your specifications, our CNC machining services at ProleanTech can be the one-stop solution. We provide comprehensive polyurethane machining services, from DFM feedback and material selection guidance to full-scale production and surface finishing.

FAQs

What are the disadvantages of polyurethane?

Some key disadvantages of Polyurethane are the emission of volatile organic compounds and UV-exposure sensitivity.

What is the lifespan of polyurethane?

Polyurethane lasts from 20 to 50 years, depending on its composition and grade.

What tools do you need to machine polyurethane?

Tools needed for polyurethane machining are sharp two-flute end mills, high-speed drills, and turning inserts. The specific tool choice depends on the machining process you are performing.

0 Comments