Molding is not always the right solution for HDPE parts, especially when you are working with low-volume production of complex and thick designs; Plastic CNC machining is preferred in such cases. CNC milling, turning, drilling, threading, and other processes can shape the HDPE workpieces into the desired shape, maintaining tight accuracy.

Additionally, it does not require expensive tooling and is economical for both prototyping and low-volume production. Understanding the HDPE material and its various aspects related to machining can help you make informed decisions during production and achieve precise results.

Let’s discuss properties of HDPE, machining processes, tooling considerations, benefits, and industrial applications.

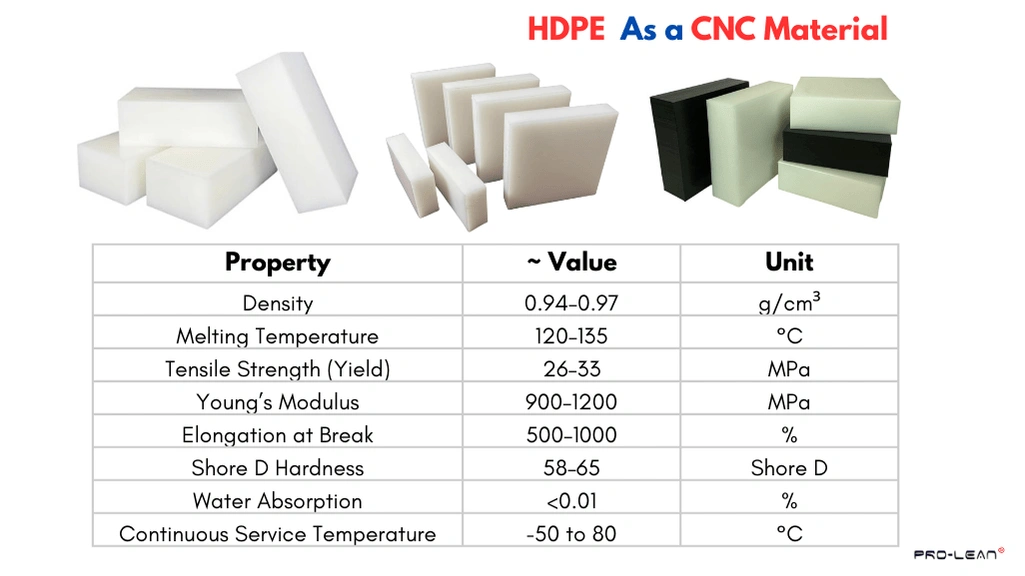

What are HDPE plastics? HDPE As a CNC Material

High-Density Polyethylene (HDPE) is a common engineering polymer used in various machining applications, ranging from food processing items to industrial fittings. This thermoplastic material provides excellent corrosion resistance, impact strength, machinability, and low moisture absorption.

The internal composition of HDPE involves highly crystalline ethylene monomers arranged in a long-chain form. This linear polymer structure results in tightly packed chains with minimal branching, leading to a high density.

Next, how is high density polyethylene made? It involves the polymerization of ethylene gas at controlled temperatures and pressures in the presence of Ziegler-Natta catalysts or chromium catalysts.

Raw petroleum, like naphtha, is heated to produce ethylene gas, which is the primary building block for HDPE. Then, the gas is processed for polymerization in specialized reactors; a loop/autoclave reactor is most common, where ethylene is fed with a hydrocarbon diluter in the presence of a catalyst.

What Are the Properties of HDPE?

HDPE properties

In any type of plastic parts machining, material properties directly impact the tooling, machining variables, accuracy level, and even the functionality & performance of machined parts. Therefore, let’s look at the key physical, mechanical, and chemical properties of HDPE.

- Corrosion Resistance: HDPE is highly resistant to corrosion and abrasion, and it does not form rust when exposed to humidity.

- Tensile Strength: HDPE has high tensile strength, 20 MPa or 2,900 PSI.

- Impact Resistance: It is a tough polymer and offers high wear and impact resistance.

- Recyclability: The materials can be recycled after the product lifecycle, retaining all original properties.

- Biocompatibility: HDPE is biocompatible and can be machined to make surgical tools & some implantable devices.

- Food Processing: HDPE is hygienic, and various FDA-approved grades are available for producing food-processing items.

- Chemical Inertness: HDPE exhibits inertness towards acids, alkalis, and various solvents.

- Thermal Behaviour: Although it has a melting point of approximately 135°C, its properties remain stable within this range.

- Moisture Absorption: HDPE plastic absorbs minimal (or no) moisture in humid environments.

Try Prolean Now!

HDPE CNC Machining Processes

One of the key reasons for flexibility with complex designs is the diversity of machining processes that can be used in HDPE machining. Based on the part’s geometry & desired specifications, you can choose CNC milling, turning, drilling, routing, and other processes.

Let’s briefly elaborate on four HDPE machining processes: Milling, Turning, Drilling, and Routing.

CNC Milling

HDPE CNC milling

Milling involves the use of rotating cutting tools to shape a stationary HDPE workpiece, typically in block form. This process can create complex 3D parts with irregular contours, slots, pockets, and other features.

- Feed and Speed: Moderate feed, with air blast or misting cooling.

- Tooling: Carbide end mills (single or 2-flute) and O-flute cutters.

- When to Use: When you need parts with complex 3D contours and intricate internal features.

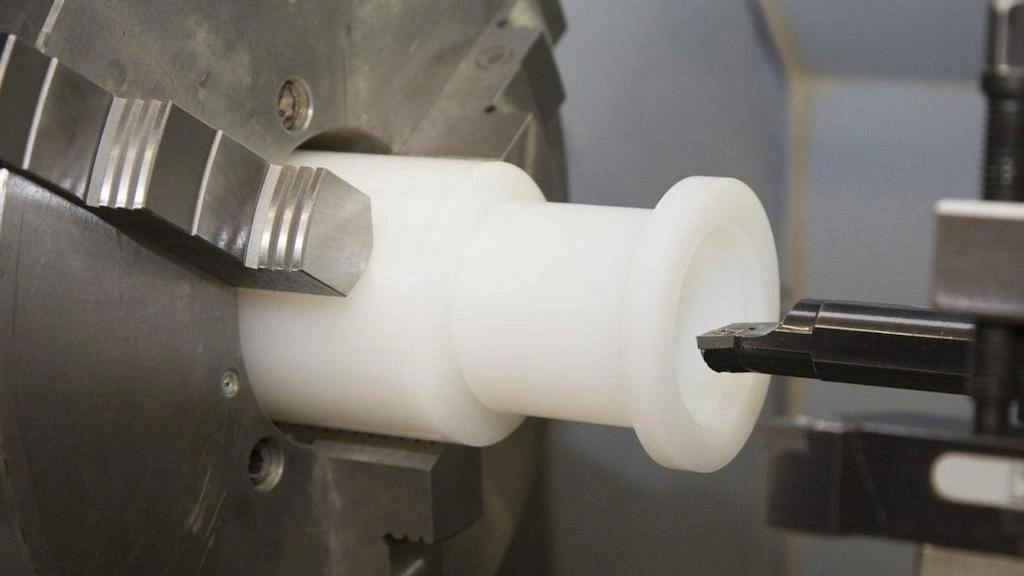

CNC Turning

HDPE CNC turning

In turning, the HDPE rod-like workpiece rotates, whereas the tool moves in X and Z directions to feed the material and create the desired shape. It is suitable for parts with cylindrical geometry. Meanwhile, CNC lathes or turning centres are used to turn HDPE parts.

- Feed and Speed: Moderate speed, but a higher feed rate than milling.

- Tooling: Conventional sharp lathe tooling and carbide inserts.

- When to Use: Round components, both cylindrical and hollow cylindrical

CNC Drilling

Drilling machining involves the downward movement of a rotating drill bit that penetrates the materials and creates blind or through holes. Bits are designed in a way that their flute structures allow upward evacuation of chips. Meanwhile, the size of the hole is determined by the size of the tool.

- Feed and Speed: Moderate speed and slower feed to avoid heat buildup.

- Tooling: HSS or carbide bits

- When to Use: For precise holes of different sizes and internal channels.

CNC Routing

Routing HDPE

The CNC routing process uses rotating router bits to cut, engrave, and shape flat HDPE workpieces or sheets. Routers can machine large surface areas and remove a high amount of materials rapidly.

- Feed and Speed: High speed ( up to 24,000 spindle rpm)

- Tooling: Upcut spiral, compression, or single-flute bits.

- When to Use: Ideal for shaping flat & panel parts, and crafting features on them.

Try Prolean Now!

What Are the Applications of HDPE CNC Machining?

CNC-machined HDPE parts

Due to the versatile physical, mechanical, and chemical properties of HDPE and its affordable material cost, many industries choose HDPE as a CNC material to make robust and durable components.

Next, let’s look at the HDPE applications in automotive, medical, electronics, food-processing, chemical processing, and marine industries, with machining high density polyethylene examples.

| Industry | Benefits | Application Examples |

| Automotive | Low-cost, lightweight, and impact-resistant | Coolant reservoirs, bushings, wear strips, fuel tanks, and mounting plates |

| Medical | Chemically inert, non-toxic, and biocompatible | fluid containers, equipment panels, lab trays, tubing, surgical tools, and medical device components |

| Electronics | Good insulator, moisture resistance, and durable | Terminal blocks, circuit casings, protective covers, device internal parts, conduits, and connector frames. |

| Food Processing | Hygienic surface, easy to clean, and bacteria-resistant | Cutting boards, food containers, conveyors, and sanitary tanks |

| Chemical Processing | Chemical and corrosion resistance, toughness, and durability | Storage tanks, custom pipe fittings, seals, gaskets, and manifolds |

| Marine | Saltwater resistance, lightweight, high impact strength | Marine spacers, buoys, hatch panels, wear strips, marine brackets, intake components |

What Are the Challenges in HDPE Machining?

HDPE is a flexible and heat-sensitive material, so heat buildup in the chip and tool can cause deformation and dimensional inaccuracy. Besides this, there are other HDPE fabrication and machining challenges. Let’s discuss them.

Heat Build Up

Heat buildup on cutting tools and chips is a primary challenge in HDPE or any other thermoplastic machining. It not only influences the machining dimensions, but also causes burn marks and material melting. Therefore, perform a trial job and optimize the feed, speed, and machining angle. Additionally, employ an effective cooling system.

Dimensional Inaccuracies

Temperature changes during the machining process can lead to material shrinkage near the tool. This causes a significant challenge in maintaining dimensional tolerances.

Wear on Cutting Tool

If the feed rate or cutting speed is too high, it increases the friction between the tool and the HDPE workpiece. This friction leads to rapid tool wear, further causing poor tolerances and surface finish. Inspect tool wear regularly and use the right machining parameters.

Best Machining Practices for HDPE Material

To avoid the machining challenges and potential defects, there are many standard industry practices, including machining variables, tooling, workpiece clamping & alignment, and cooling.

The list below outlines six key HDPE machining practices.

- One or Two-flute Tools: Choose lower flute cutting tools, which help with seamless chip evacuation. Additionally, ensure tools are made with carbide or HSS to withstand the cutting force.

- Optimize Machining Variables: Run a computer simulation to predict the heat generation and correct feed, speed, and depth accordingly.

- Workpiece Clamping: Firmly clamp the HDPE workpiece. Loose work securing increases the machine vibration and instability. Additionally, align the work with the cutting tool correctly.

- Cooling System: Use air-mist cooling or a compressed air setup to prevent heat-related damage.

- Post-processing: After custom cut HDPE, perform finishing passes or deburring operations to refine the surface and edges.

- HDPE Annealing: Perform annealing (controlled heat-treatment) process to machined HDPE parts. It releases the internal stress built during machining and avoids cracks.

Read More: PVC CNC Machining

Summing Up

Overall, HDPE machining is a versatile manufacturing process used to produce strong, durable, and chemically inert plastic parts. Milling, turning, drilling, routing, and other specialized processes can be applied based on the desired part geometry and involved internal features. However, heat management is the key challenge to address so that you can avoid burning marks, melting, tool wear, and dimensional inaccuracies.

If you are looking for a manufacturer that can easily tackle the HDPE machining issues and produce defect-free parts exact to designed specifications, ProleanTech is the best choice. Our one-stop CNC machining services deliver high-quality custom parts made of HDPE and other thermoplastics.

FAQs

What is the machining tolerance of HDPE?

HDPE machining offers a general tolerance of ±0.125 mm, and ±0.05 mm is achievable with advanced CNC machinery.

What is the downside of HDPE?

Low melting point, stiffness, and susceptibility to creeping under continuous load are the main downsides of HDPE material.

Does HDPE crack easily?

No, HDPE does not crack easily. It can withstand impact forces, unless there is high mechanical stress and hard chemical exposure.

0 Comments