Sheet metal punching

Have you ever noticed various shapes and sizes of holes in automotive panels, electronic enclosures, brackets, and perforated metal sheets? They are all made with sheet metal punching & stamping services, which provide tight accuracy, repeatability, and cost benefits in high-volume production.

Metal punching involves using a metal pressing punch with a profile similar to the hole shape & size to sheet metal against the die tooling. Then, the edges of the punch cut the material via shear force.

This article will discuss the metal punching process, its advantages and disadvantages, applications, and common mistakes to avoid. At the end, we will also compare punching with stamping, blanking, and laser cutting.

What is Meant by Sheet Metal Punching?

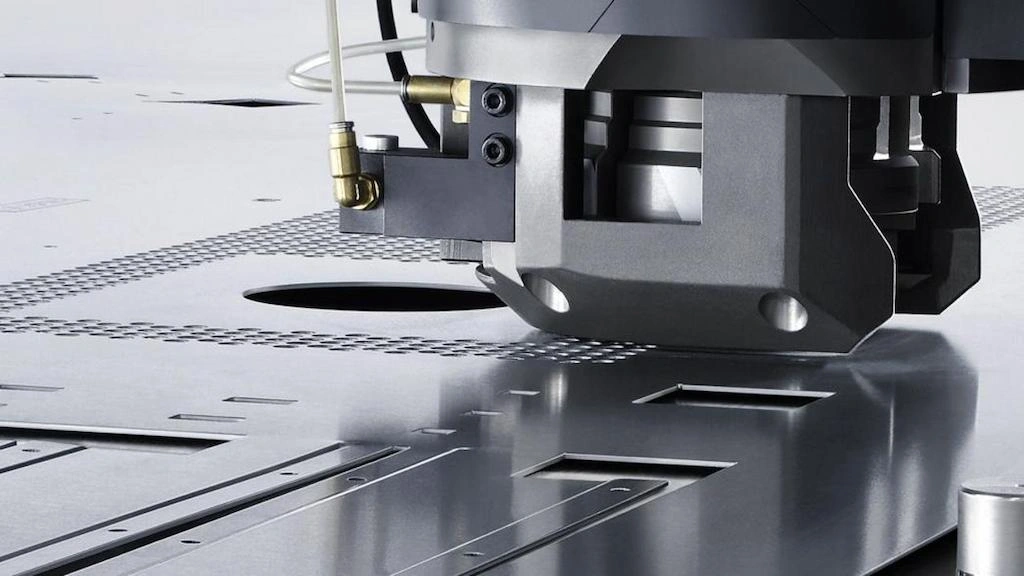

metal punching process

Metal punching is a critical operation in sheet fabrication work, used to create holes, slots, and other related features. A die and punch-press shear the material and make the holes, cutouts, pierces, and louvers of the desired shape and size.

A punch with an identical profile to the hole shape impacts the sheet metal against the counterpart die. The impact of punch-edge shears on the material produces holes, leaving the scrap below.

You can punch mild steel, stainless steel, aluminum, brass, galvanized steel, copper, and many other materials with sheet thicknesses up to about 6 mm or higher, depending on the material type. Moreover, versatile punching operations apply to these metals, including single punching, multiple punching, cluster punching, and progressive punching.

Types of Equipment Used for Sheet Metal Punching

Types of punching presses

Punch presses are the key equipment for sheet metal hole punching, which accommodate the punch and die sets to perform the operations and shape the cutting profiles of holes. These are either hydraulic or mechanical presses controlled by an electronic unit.

It also requires tool holders, sheet supports, clamps, deburring systems, and scrap removal mechanisms. Each of the tooling and individual systems is essential for a precise and efficient metal punching station.

Let’s elaborate further on three types of punching presses: Manual, CNC, and Stud-driven punches.

Manual Punch Press

The manual punch presses are operated manually by pulling a mechanical lever that transfers the hand power into a powerful punching stroke, shearing the sheet against the matching die. Then, the mechanical link itself repositions the punch after striking.

Although manual presses are not suitable for heavy-duty and large-volume projects, they provide greater flexibility and customization.

CNC Punch Presses

These are computer numerical control (CNC) integrated punching presses, where computer instructions control the movement and positioning of punch heads, stroke depth, feed rate of metal sheets, and the punching sequence. Additionally, CNC also coordinates with other metal forming operations to streamline the process.

Stud-Driven Presses

This type of punching press uses a threaded ram or screw-driven systems that allow for applying gradual pressure to the punching ram to create holes. It is less common and suitable for manual punching on a thicker sheet.

Try Prolean Now!

How Does the Punching Process Work?

working of metal punching

The simple working mechanism involves pressing and punching the punch ram, which has a profile identical to the hole shape and size, carried out by mechanical or hydraulic means. However, there is a series of individual steps for this, including part design, die & punch tooling, machine setup, punch impact, deburring, and final inspection.

The list below outlines the steps involved in the sheet metal punching process.

- Design & Programming: First, create a 2D/3D design of parts with punched holes, outlining dimensions & tolerances. Then, generate a CNC program file if you are using CNC punching machines.

- Material Selection: Select a suitable material and determine the appropriate sheet thickness for your applications.

- Die & Punch Tooling: If custom dies and punches are required, design and manufacture them using CNC, casting, EDM, or any other suitable method. Otherwise, select the type and size of die-punch tooling.

- Machine Setup: It involves feeding setup, die clamping, punch positioning, and uploading the CNC program file to the machine. Additionally, set punching speed, dwell time, and sequence of punching.

- Punch Striking: After setup, run the program, and the punches will strike the sheet, following the pre-determined speed and sequence.

- Deburring: After the punch shears the material and creates holes, the edges may not be smooth and clean. So, they need deburring.

- Inspection & Quality Control: Inspect for any surface defects on parts. Then, verify the dimensional accuracy and quality through measurements and testing.

Types of Sheet Metal Punching

Based on the specific metal forming operations used for punching, it can be categorized into various types, such as notching, slotting, piercing, lancing, embossing, and blanking.

The table below outlines the common types of sheet metal punching operations.

| Operation | What it does? | Typical use |

| Piercing | Cutting a hole of the desired shape through the sheet. | Fastener holes |

| Notching | Cutting out material from an edge or corner. | Tab/fit features |

| Slotting | Creating a long rectangular or oval opening. | Wiring, tabs |

| Blanking | Removal of a complete piece from the sheet | Washers, parts |

| Lancing | Partial cut, leaving a tab or lip | Standoffs, vents |

| Embossing | Local forming of a raised/recessed detail. | Strengthening, logos |

| Perforating | It creates a repetitive pattern of small holes | Ventilation, aesthetics |

Try Prolean Now!

How much does CNC Punching Cost?

CNC punching is cost-effective than other processes like waterjet cutting, shear cutting, and laser cutting, especially for larger production volumes. Still, the initial investment for tooling and setups can be expensive, ranging from $1,000 to $10,000. However, per-part tooling costs become significantly lower in mass production.

The exact amount for metal punching depends on several factors, like material type, die & tooling, desired tolerances, finishing requirements, and lead time.

If you want to know the exact cost, upload your design and get a quote with a clear cost breakdown.

Strategies and Practices to Avoid Metal Punching Mistakes

Although punching sounds simple, it requires different strategies to avoid mistakes, such as material galling, burrs on edges, and deformation.

The following are the five punching strategies based on industry practices.

Avoid Heat Buildup

If the strike rate of punches is too high, the material cannot dissipate enough heat, which causes work hardening. Therefore, ensure a right interval between punches to cool down the punch and the worksheet. Furthermore, if the punch remains in contact with the sheet for too long, causing heat buildup, it can lead to metal galling.

Use Laser Cutting for Small Holes

If the size of the hole(radius) is smaller than two times of sheet thickness, you can use laser cutting as an alternative to punching. It helps to avoid deformation and defects.

Deburr the Edges After Punching

The punched holes might contain deburrs, caused by the rapid strike of the punch edges. Therefore, deburring becomes essential for maintaining dimensional stability, ensuring safety, and achieving aesthetics. The common deburring techniques include sandblasting, electropolishing, and bead blasting.

Determine the Power of the Metal Punching Machine

Calculating the power of the sheet metal punching helps ensure the required punching force, which is crucial for optimal performance.

Here is the formula to calculate punching force.

Force (F) = P x t x σₜ x k (P: Hole perimeter, t: thickness, σₜ: Tensile strength, K: shear factor)

Partner with Expert Manufacturer

Whether you are only punching dies or fully-finished punched metal parts, partner with an expert manufacturer like ProleanTech, which can meet all your requirements. This way, you can leverage the manufacturer’s capabilities and expertise for your project.

Industrial Applications of Sheet Metal Punching

Metal punching parts

The uses of metal punching methods are widespread, from simple architectural metal work to electrical enclosure fabrication and auto parts manufacturing. Often, it combines with other sheet metal operations to form sheet metal parts.

Let’s look at the applications of sheet metal punching in the electrical, automotive, aerospace, architecture, and home appliance industries.

Electrical Industry

Punching is used to make repeatable holes in electrical enclosures for ventilation, cable connections, and mounting brackets. For example, perforated panels, louvered vents, cutouts for connectors, and panel brackets.

Automotive Industry

Different shapes of accurate holes are needed in various sheet metal auto parts. Metal punching allows for precise hole making with excellent repeatability in various automotive components. For example, seat frame brackets, heat-shield perforations, body inner panels, clip & rivet holes, etc.

Architecture Industry

Precise holes, cutouts, and louvres on various architectural items are made with metal punching operations. For example, perforated façade panels, acoustic panels, claddings, and aesthetic parts.

Home Appliances

In the home appliances industry, sheet metal punching is used to make precision openings and assembly features in high-volume consumer appliances. For example, ventilation slots, mounting brackets, grill panels, hinges, and so on.

Advantages of Sheet Metal Punching

The list below outlines the advantages of metal punching in sheet metal fabrication:

- High Production Speed: CNC systems automate the punch movement, feeding, and punching sequence, thereby improving punching speed.

- Tight Tolerances: CNC punching enables the creation of holes with accuracy as low as ±0.1 mm or lower.

- Repeatability: Sheet metal punching holes are highly repeatable due to the use of automation.

- Cost-Benefit: Although the tooling incurs a significant upfront cost, CNC die punching is cost-effective for medium- to high-volume productions.

- Material Versatility: You can punch aluminum, steel, stainless steel, titanium, and many other metal sheets as thick as 6 mm.

Disadvantages of Sheet Metal Punching

The list below outlines the disadvantages of metal punching in sheet metal fabrication:

- Forming limitation: CNC punching is limited to hole creation. It can not be used for metal forming parts.

- High Tooling Cost: Die and punch setups require a high upfront cost, making them unsuitable for prototyping and small-volume projects.

- Material Wastage: It leaves relatively higher scraps than other methods; the larger the hole, the higher the material wastage. But scrap can be recycled.

- Safety Concerns: The punching process needs strict safety measures for both operators and the working space.

Metal Punching Vs Blanking

The main difference between punching and blanking is that the punched out profile (blank) is the desired part in blanking, whereas it is considered scrap in punching. A punch is designed with a profile based on the size and geometry of the required part, which strikes the metal sheet against the blanking die, cutting through the material.

The table below provides a brief comparison of punching and blanking:

| Feature | Metal Punching | Blanking |

| Process | It involves removing local material to create a hole. | It cut out a complete part from the sheet as the blank |

| Result | Sheet with holes and its scrap | Separated parts; scrap are offcuts |

| Tolerance | Moderate tolerance and often need secondary finishing | Higher accuracy and better edge finish |

| Tooling | Simple punches and high-speed production | Dies are similar but may need stripping |

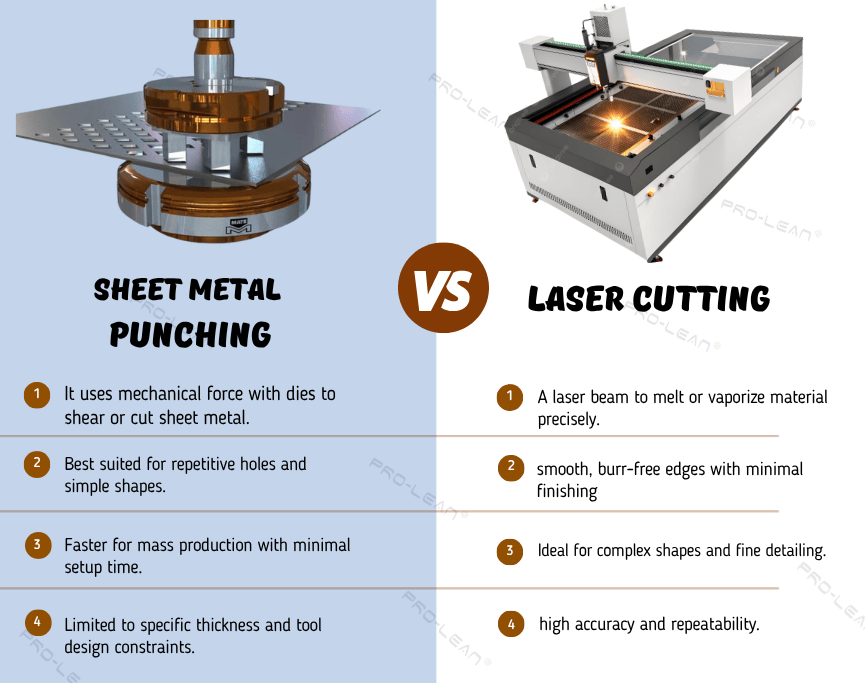

Metal Punching Vs Laser Cutting

The laser cutting process utilizes a high-focused laser beam that precisely strikes the sheet, melting the material to create holes and other features. Meanwhile, CNC systems control the movement of the laser head.

Comparing punching vs laser cutting, laser cutting can make more complex geometries with tolerances ±0.1 mm or better. Consequently, it can also cut through hard and non-metallic materials. Since no tooling is required, laser cutting is also cost-effective for prototyping and small batch production.

Metal Punching Vs Stamping

Punching vs Laser Cutting

Punching is a part of stamping; it is combined with various other metal forming methods in a sequence to produce complex sheet metal parts.

What is a Stamping? It is a sheet metal shaping process that involves punching, cutting, bending, deep-drawing, and other operations. Meanwhile, punching only focuses on making holes & opening related features.

Let’s take a look at the comparative table of punching vs stamping below:

| Feature | Metal Punching | Metal Stamping |

| Operations | Cutting only | Cutting and forming combined |

| Purpose | Create openings in a sheet | Produce finished or shaped parts |

| Tooling | Simple punch and die | Progressive or compound dies |

| Output | Perforated sheet | Formed component |

| Complexity | Low | High |

| Cost | Lower tooling cost | Higher setup, lower per-part cost |

Summing Up

Although it sounds simple, metal punching is a versatile operation in sheet metal fabrication. It has extensive applications across various industries for creating precise holes, cutouts, slots, piercings, and other similar features. Consequently, the punching process provides repeatability, high speed, and cost-benefit in high-volume fabrication projects.

Moreover, you must ensure the use of the right type of punching presses, proper tooling, and careful execution of the process to achieve high-quality results.

For further information, contact us and talk to an engineer.

FAQs

What is punching in sheet metal?

Punching is a metal part fabrication process where a punch forces through sheet material into a die to shear out holes or shapes.

What are the different types of sheet metal punches?

The common types of sheet metal punches include plane punch, knockout punch, draw punch, compound punch, and progressive-die punch.

0 Comments