Hot foil stamping

Did you know how attractive logos & designs are printed on the electronic enclosure, consumer packaging, and other products? Hot foil stamping is used for this. A die with an engraved design above a thin foil transfers the design onto the substrate surface using heat & pressure.

Not only a simple design imprint, but it can also provide different textures and aesthetic effects, like holography. Understanding the process, die, and other aspects can help you to print a custom design into your parts without any defects.

Let’s discuss the hot stamp printing process, benefits, limitations, and applications in detail.

What is Hot Stamping?

Hot stamping is a process that imprints a design, pattern, image, or lettering onto the surface of manufactured items using heat and pressure. A heat stamping die and special foils are used for this. Although this process does not form the functional components like sheet metal stamping, it has extensive uses in decoration, labelling, and branding.

More than metallic items, it applies to leather, fabric, wood, and other materials. You can customize the design and color combinations to suit your preferences. Additionally, the print can have a clear, shiny, pearlescent, or holographic effect.

Key Points About Hot Stamping

- Hot stamping, also known as foil stamping, is used for decorative purposes & branding.

- An engraved die is the primary tool for this process, typically made with brass, copper, or magnesium.

- The die is installed on the machine, which applies pressure & heat.

- This printing method can be used on a variety of materials to imprint thousands of designs.

How does Hot Foil Stamping Work?

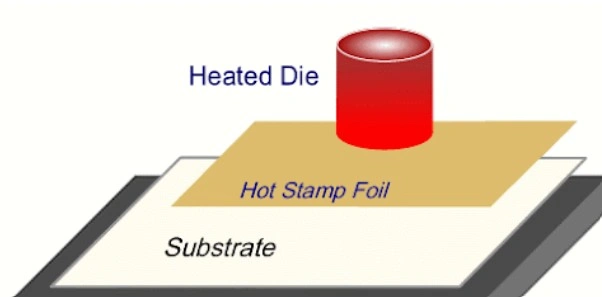

Hot stamping process

The hot foil stamping die is engraved with the design that needs to be printed, and heated before the process, whereas the foil sits between the engraved and the substrate surface. As pressure is applied to the heated die, it activates the foil’s adhesive layer and transfers the design onto the surface.

Here, the printing foil does not melt and prints the surface through its deposition. Instead, the foil contains several thin layers with pigments & glues, which are responsible for this. Meanwhile, pressure stabilizes the print.

The foil can be both metallic or non-metallic, whereas the thickness ranges from a few microns to 0.030 mm. Additionally, the foil contains three different layers: color, adhesive, and release layer.

- Color layer: It is made with a shiny metallic sheet or pigment, responsible for the decorative finish.

- Adhesive layer: The pressure and heat fuse the color layer onto the substrate via the adhesive layer, which melts and secures the print color permanently.

- Release Layer: It is made with a wax or silicone-based coating, which allows the color layer to detach from the surface.

Material Considerations for Hot Stamping

As we have discussed, hot stamping can be used to print on metal, alloy, composite, leather, and fabric surfaces. But you must consider different factors during the process, like thermal properties of the material, die pressure for printing, etc.

The following are four key material considerations you can refer to during hot print stamping:

- Consider the material type and its surface to decide the right foil diameter so that the foil can form a strong print bond with the surface.

- Consider the thermal sensitivity of the material; paper, fabric, and other materials are susceptible to heat.

- If the substrate surface has a coating, ensure it does not block the foil’s adhesiveness.

- Surface texture also matters to print quality; low-porosity surfaces are more favourable for hot print stamping.

Steps Involved in the Hot Stamping Process:

Hot stamping mechanism

The hot stamping process starts with design creation, followed by die manufacturing, printing, and post-processing.

You can refer to the following steps to print your part/product surface with hot stamping:

Step 1: Design & Die Manufacturing.

First, create the design you want to print on the part/products using computer design software. This design is the primary framework for die design and manufacturing. Then, choose a suitable stamping material and engrave it with the exact negative shape of the print design. Processes such as CNC machining, laser cutting, etching, and engraving are employed based on the design complexity.

Step 2: Foil Selection and Setup.

There are several types of stamping foil, including metallic, pigment, matte, and holographic. Choose the correct foil and corresponding color & adhesive layers. Load the foil roll to run the polyester carrier film between the die and the substrate.

Set the die into the pressure machine and ensure the die, foil, and substrate surface are correctly aligned. Consequently, set the correct heating temperature and pressure.

Step 3: Printing Process

Applying the heat & pressure to the die, heat activates the foil adhesive and softens the release layer, then the adhesive contacts and bonds to the substrate only where the die touches. Meanwhile, the control of temperature is crucial for design transfer, edge quality, adhesion, and finish.

Step 4: Inspection & Quality Control

Inspect the print for complete transfer, cracking, contamination, and finish quality. If required, coat the print with a wear & chemical resistance layer. Furthermore, you might need to adjust the setup and process if any defects are found.

Hot Stamping as a Metal Forming Process Vs. Hot Foil Stamping

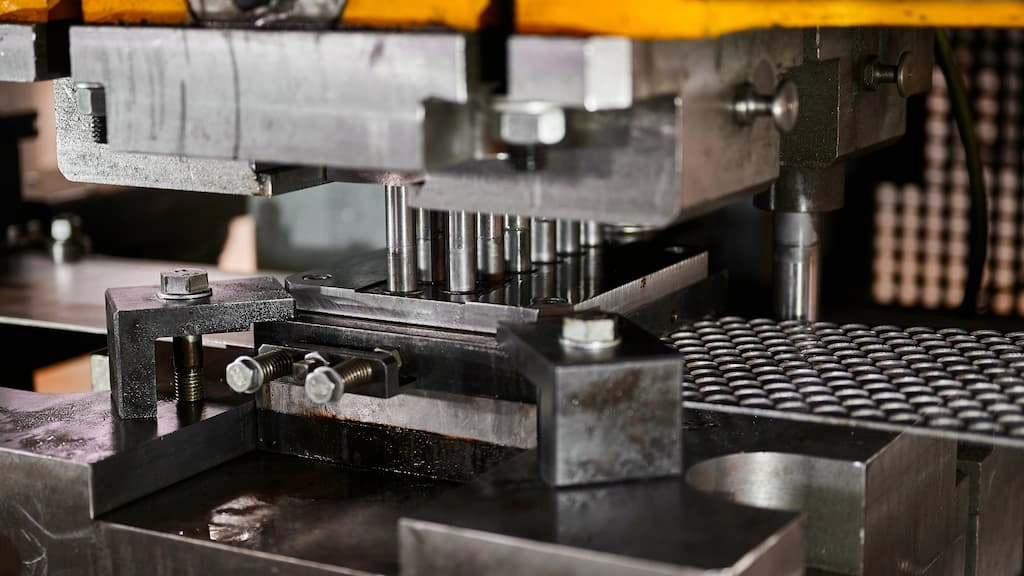

Sheet metal stamping

Often, people confuse hot foil stamping with the common metal stamping process that is used to form sheet metals into complex parts. Moreover, metal stamping also involves the worksheet before stamping, especially for thick sheets with low ductility. But, it is nothing similar to the “hot foil stamping” process. Unlike hot stamping, you can not stamp leather, plastic, fabrics, or other non-metallic materials. Only metal and alloys are considered as metal stamping material.

Let’s look at the comparison table.

| Aspect | Hot Stamping (Metal Forming) | Hot Foil Stamping |

| Purpose | It shapes and strengthens heated metals into structural components. | Transfers metallic or colored foil for decorative finishes. |

| Material | Steel, aluminum, and other heat-treatable metals. | Paper, plastic, leather, and packaging substrates. |

| Process | Metal is heated, pressed, and cooled to achieve form and hardness. | Heated die presses foil onto the surface using heat and pressure. |

| Outcome | Produces durable, high-strength parts for the automotive, aerospace, and electronics industries. | It creates shiny, aesthetic logos, texts, and surface designs. |

| Temperature | 600–950 °C for metal forming. | 100–200 °C for foil transfer. |

Read Moe: Automotive Metal Stamping

Benefits of Hot Stamp Printing:

The hot stamp print offers excellent quality, customization, durability, and aesthetic appeal. Furthermore, its compatibility with diverse materials enhances its applications across the industries. You can apply hot stamping on wood, leather, plastics, metal, composites, etc.

Let’s look at the major advantages of hot foil stamping:

- Diverse Printing Effects: It can generate different effects with the printed design, enhancing the aesthetic appeal. Additionally, any color combination can be used.

- Customization: You can print a logo, letters, images, or any custom design with a vibrant look.

- Material Compatibility: Hot stamp printing is compatible with any type of manufacturing material, including leather, plastics, and fabric.

- Durability: The printed design resists mild chemicals, corrosion, wear, and fading. So, the print lasts for several years.

- Repeatability: As the hot stamp die is reusable, you can print identical designs in a large number of parts with consistent quality.

Limitations of Hot Stamp Printing

Although hot stamping has numerous benefits in the printing of manufactured items, it has some limitations on print size, foil properties,

The limitations of hot stamping are as follows:

- Some materials, like leather, require specialized foils and are also challenging to control when it comes to stamping variables.

- The size of letters or features is limited to 0.3 mm thickness. You can not print extremely small letters and numbers with high definition.

- Another limitation is printing on curved and irregular surfaces, which require a perfectly flat or nearly flat surface.

Applications of Hot Stamping

Applications of hot stamp printing

The uses of hot stamping range from the packaging of consumer items to the marking of auto components like dashboards and control knobs. Whether it is a decorative item or instruction panels for machinery, you can use this technology.

The table below outlines the application examples across different industrial sectors:

| Industry | Why Hot Stamping? | Application Examples |

| Packaging | Premium metallic or holographic finishes to convey the sense of luxury. | Gift boxes, wine and spirits cartons, chocolate packaging, perfume boxes, etc. |

| Cosmetics | Elegant, durable finishes with long shelf life | Lipstick sleeves, compact cases, skincare jar caps, perfume bottles, mascara tubes, etc. |

| Security | Anti-counterfeit protection using holographic or tamper-evident foils. | Holographic seals, tax stamps, ID cards, event tickets, warranty labels, certificates. |

| Automotive | Durable, heat- and abrasion-resistant finishes | Dashboard, control knobs, air vent trims, gear indicators, interior decorative panels, etc. |

| Electronics | Precise &long-lasting branding on plastic or metal parts. | Remote controls, headphone logos, appliance panels, speaker grilles, TV bezels. |

Different Types of Hot Stamping Dies

Foil stamping dies

Unlike in custom metal stamping, material for hot stamp dies does not need to be extremely tough; they only require a mild level of hardness to withstand pressure and good thermal conductivity. Therefore, magnesium, copper, and brass are the typical choices.

Now, let’s look at the type of hot stamping dies in brief: Copper, Brass, and Magnesium hot stamping:

- Copper Hot Stamp Die: Copper dies can be easily engraved and etched with fine detail. It resists pitting and the risk of image damage.

- Brass Hot Stamp Die: Brass has enough hardness to withstand the pressure and heat. Dies made with brass are easy to make and can be used for multi-level printing.

- Magnesium Hot Stamp Die: Magnesium dies are lighter in weight and cost-effective than copper & brass. However, it has a shorter life than copper, suitable for small runs.

Key Factors Affecting Hot Stamping

The following are some critical considerations for the hot stamping process:

- Die Temperature: The temperature should be just enough to soften the adhesive layer. Intense heat causes bleeding of the adhesive foil.

- Die Pressure: The pressure applied to the die must be enough to press the substrate surface while uniformly distributing the stress.

- Press Time: The time that die remains on the substrate surface is called press time; it must be chosen based on the die pressure & temperature.

- Die design: Consider die depth, halftone detail, and edge radii of the die as they affect print definition and heat transfer.

Alternative to Hot Foil Stamping

In addition to hot foil stamping, various printing methods are available for manufactured items, including metallic inks, cold foiling, embossing, and screen printing.

- Metallic links: This method uses inks with metallic print designs on the substrate surface. It is more economical than hot stamping.

- Cold Foiling: It is the process of printing manufactured parts using UV-curable adhesive, so intense heat is not needed. You can use cold foiling to print heat-sensitive materials.

- Embossing: It involves adding 3D textures by precisely creating the recesses, without any foil transfer.

- Screen Printing: This method applies thick metallic inks to print the design. You can use this for durable metallica coverages.

Part and Tool Design to Prevent Defects for Hot Stamping

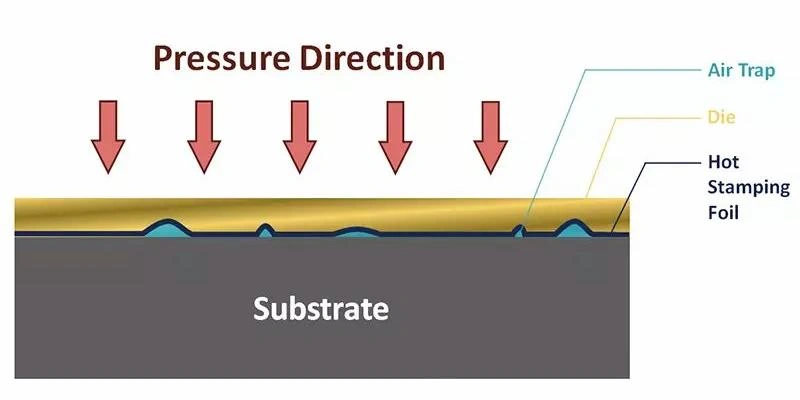

Part and tool(die) design are critical to avoid the risk of printing and surface defects. Because tooling directly influences the implication of heat, pressure, and foil transfer quality.

The following are some key considerations for parts and tool design for hot stamping.

- Use die relief to facilitate the uniform pressure distribution throughout the design, and the contact surface must be flat.

- Optimized the engraving depth and edge radius to prevent foil tearing and improve the clean release of the adhesive layer.

- Use nests or cavities for thin or flexible parts. You can select backing material such as silicone pad, steel anvil, or polymer roll to match the desired give and add a vacuum for cycle repetition.

- The die material must be selected based on the required heat distribution and production volume of printed items.

- If needed, add venting and drainage ports. They help to avoid trapped air and foil wrinkling.

Summing Up

Overall, hot stamping is a high-quality permanent print on the surface of manufactured items, regardless of material type. This repeatable and cost-effective method is beneficial to print a wide range of parts/products, from decorative designs on fabric to custom branding on electronic enclosures. At the same time, the quality of the stamping die and foil selection heavily influences the printing results.

ProleanTech, we can make custom dies for you and print custom designs on the manufactured items, whether they are sheet metal parts, CNC-machined items, or plastic components. For further inquiry, you can contact us or upload the design to get a quote. Our engineers will guide you through the process to achieve optimal results.

FAQ’s

What are the disadvantages of hot stamping?

The main disadvantages of hot stamping are: the need for precise control of pressure and temperature, higher tooling costs, and limitations on irregular surfaces.

Is hot stamping the same as embossing?

No! Hot stamping differs from embossing; embossing raises the surface through forming forces, whereas hot stamping deposits colour for printing.

Is hot stamping permanent?

Yes. Hot stamping is permanent. It resists fading, abrasion, and corrosion, resulting in a longer lifespan.

0 Comments