Lightweight Metal Grades: Grades, Advantages & Applications

Lightweight metals are transforming industry and engineering today. They provide excellent strength, low weight, and exceptional corrosion resistance for a variety of uses.

At ProleanTech, we specialize in custom CNC machining and deal with lightweight metals such as aluminum alloys, titanium alloys, and magnesium alloy products. Our experience assures exact components, efficient material utilization, and long-lasting parts.

This guide delves into lightweight metals, their advantages, essential alloys, surface treatments, and how they beat standard metals in strength-to-weight efficiency.

What Are Lightweight Metals?

A lightweight metal has a low density but a high strength-to-weight ratio. They’re malleable, ductile, and corrosion-resistant. Lighter metals include aluminum (2.7 g/cm³), magnesium (1.7-1.8 g/cm³), and titanium alloys (4.4-4.5 g/cm³). They are generally obtained from the earth’s crust and have been tuned for their specific qualities.

Lightweight Metal Material

These metals are widely used in automation, aerospace, building, and transportation. They are robust and long-lasting. They are therefore ideal for applications involving metal strength and CNC machining.

The production of industrial components, medical implants, and aviation parts is being revolutionized by lightweight metals. They are excellent at metal additive manufacturing, increase fuel efficiency, and withstand corrosion. In engineering projects, selecting the lightest or strongest metal allows optimal performance.

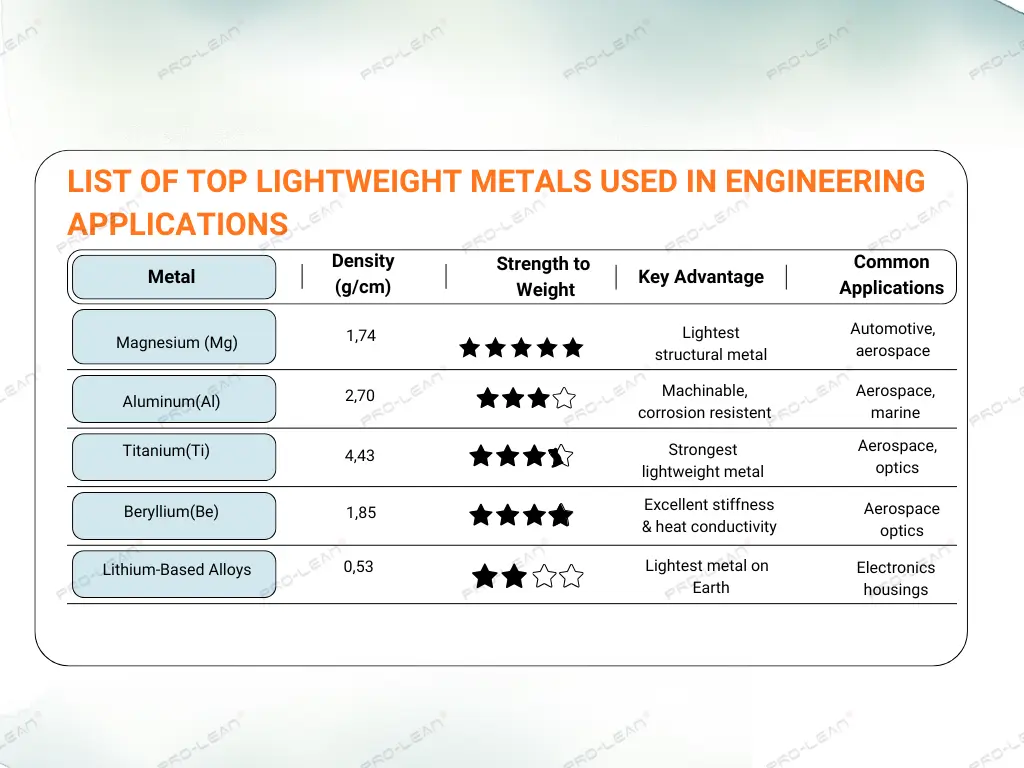

List of top Lightweight Metals used in Engineering Applications

A Closer Look at Different Lightweight Metal Materials

Aluminum alloys, magnesium, titanium, and beryllium are examples of lightweight metals. Every one of these alloys has unique machinability, density, and strength. These metals have high strength and low light content. They are perfect for specialist CNC machining services.

In extreme conditions, they perform similarly to heavier metals. Wear, heat stability, and corrosion resistance are all enhanced by contemporary coatings like PEO and anodizing.

1. Aluminum and Aluminum Alloys

Aluminum is the most adaptable lightweight metal. Aluminum is greatly valued for its machinability, corrosion resistance, and strength-to-weight ratio. CNC machining in the automotive and aerospace industries frequently uses it. With the addition of silicon, magnesium, and copper, alloys such as aluminum 6061 and 2024 improve performance.

Aluminum Lightweight Metal

Popular Grades:

| Grade | Composition / Type | Applications | Applications |

| Aluminum 2024 | Al-Cu-Mg | High fatigue strength, good machinability | Aircraft structures |

| Aluminum 6061 | Al-Mg-Si | Excellent corrosion resistance, weldable | Automotive, aerospace |

| Aluminum 7075 | Al-Zn-Mg-Cu | Very high strength, good machinability | Defense, aircraft parts |

| Aluminum 5052 | Al-Mg | Excellent formability, corrosion-resistant | Marine and construction |

Coating Enhancement:

PEO coatings offer a robust ceramic oxide layer on aluminum alloys. It increases heat resistance, corrosion, and hardness. Compared to traditional anodizing, PEO produces surfaces that are thicker and more durable. It is hence ideal for aeronautical and marine components.

Advantages:

- It is 1/3rd of the weight of the steel

- It has excellent electrical and thermal conductivity

- Aluminum alloy is compatible with PEO and anodized for enhanced security

- This alloy is economical and recyclable

With the use of anodizing and PEO, ProleanTech enhances aluminum alloys like 6061 and 7075. These alloys are ideal for lightweight, robust aerospace and marine components.

2. Titanium and Titanium Alloys

The strongest lightweight metal is titanium. It is renowned for its exceptional corrosion resistance and strength-to-weight ratio. Although it has a density of 4.5 g/cm³. This is about half of the steel. Even then, it provides comparable strength. Medical and aeronautical components commonly use titanium alloys. The cost and machinability of the titanium limit its use. Hence, it is still unmatched in situations where biocompatibility and lifespan are essential.

Common Grades:

| Grade | Composition / Type | Key Properties | Applications |

| Grade 2 (CP Titanium) | Pure titanium | High ductility, corrosion resistance | Chemical, marine |

| Grade 5 (Ti-6Al-4V) | Al-V alloy | High strength, low weight | Aerospace, implants |

| Grade 9 (Ti-3Al-2.5V) | Al-V alloy | Good formability | Aircraft tubing |

Coating Enhancement:

Titanium’s resistance to oxidation and wear increases with PEO surface treatment. It produces a surface that is resilient to high temperatures like ceramic. This is essential for car exhaust systems and jet engine components.

Titanium Alloy

Advantages:

- Titanium has an outstanding resistance to oxidation and corrosion

- It has a high ratio of strength to weight

- The surfaces of titanium treated with PEO last longer in challenging environments.

Limitations:

- Titanium is hard and difficult to machine.

- However, it is expensive than aluminum.

The CNC machining of ProleanTech ensures precise tolerances and surface requirements for Titanium alloys. They provide dependable titanium parts for applications in aerospace and medicine using accurate tools and skilled supervision.

3. Magnesium and Magnesium Alloys

Magnesium is the lightest structural metal. It has a density of 1.74 g/cm³. It is well-suited for simple CNC machining. It is used in applications requiring extreme weight reduction. Magnesium alloys are widely used in electronics, automotive, and aerospace because they combine strength and low weight.

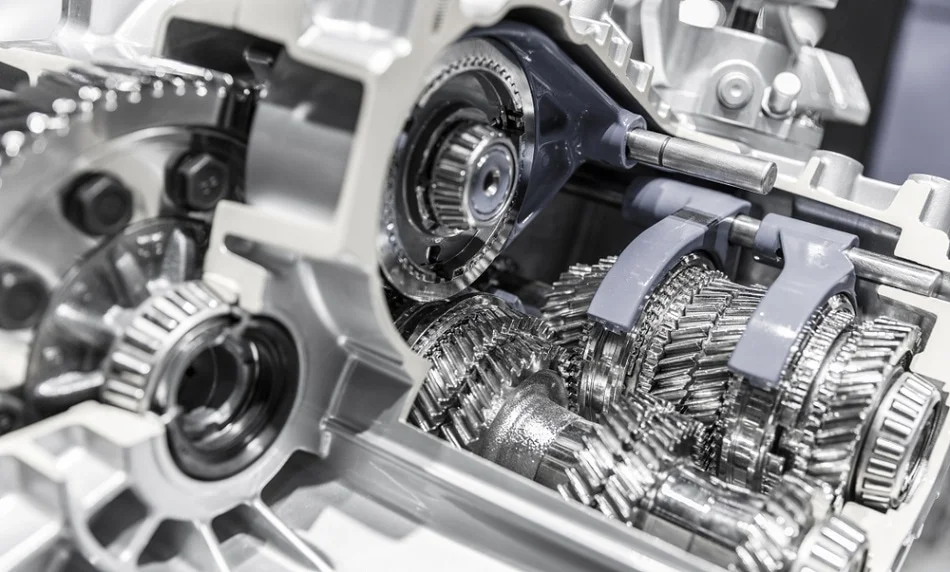

Magnesium Alloy Components in Automotive Engineering

Magnesium is prone to corrosion and is flammable. So, protective coatings are essential for industrial applications. Magnesium can safely replace aluminum in automobiles and defense components with the proper coatings.

Popular Grades:

| Grade | Type | Key Properties | Applications |

| AZ31 | Mg-Al-Zn | Ductile, weldable, corrosion-resistant | Aerospace panels |

| AZ91 | Mg-Al-Zn | Balanced strength and castability | Electronics housings |

| ZE41 | Mg-Zn-RE | High creep resistance | Defense, aerospace |

Coating Enhancement:

Magnesium that isn’t coated corrodes readily. PEO coatings made magnesium alloys suitable for marine and aerospace use. This significantly increases surface hardness, corrosion resistance, and dielectric strength.

Advantages:

- Magnesium is the lightest metal and is feasible for structural design.

- It has excellent machinability

- Magnesium has high damping ability (vibration resistance)

Limitations:

- The main limitation is that it is prone to corrosion without a coating or covering.

- Secondly, it is flammable while being machined.

Magnesium alloys such as AZ91 and ZE41 are produced by ProleanTech as substitutes for aluminum. They employ protective PEO coatings and careful machining for lightweight components. This combination reduces weight while maintaining the required strength and corrosion protection.

4. Beryllium and Beryllium Alloys

Beryllium is a light metal (1.85 g/cm³). It is rare and well-known for its strength, stability, and heat conductivity. Stiffness is more important than flexibility in precise equipment in aircraft.

Beryllium Alloy Sample

Grades and Properties:

| Grade | Key Properties | Applications |

| S-200 | Strong and stiff | Aerospace optics |

| S-65 | Balanced ductility and machinability | Precision tools |

| I-220-H | Thermal stability | Electronics, satellites |

Advantages:

- Beryllium has high conductivity and corrosion-resistant stiffness

- This alloy is exceptionally stable in terms of dimensions

Limitations:

- Beryllium is expensive and delicate.

- A controlled machining is required for harmful dust.

ProleanTech specializes in providing custom CNC machining services for all lightweight metals. PEO coatings help us increase corrosion resistance and precision. High-performance lightweight components for industrial, automotive, medical, and aerospace applications are produced by ProleanTech. Materials include titanium, magnesium, and aluminum alloys such as aluminum 2024 and 6061.

Key Physical and Chemical Properties

It is essential to comprehend the key physical and chemical properties of lightweight metals. It is helpful to find the ideal material for a particular purpose. Here is a detailed summary of chemical and physical characteristics;

Density, Strength, and Elasticity

The most important property that sets lightweight metals apart is their low density. In structural applications, it reduces weight. Many of these metals are very flexible and strong. They are therefore perfect for demanding technical jobs.

The following table contrasts metals according to their elastic modulus, yield strength, and density:

| Metal | Density (g/cm³) | Yield Strength (MPa) | Elastic Modulus (GPa) |

| Magnesium Alloy | 1.74 | 150–200 | 45–45.5 |

| Aluminum Alloy | 2.70 | 270–350 | 69–71 |

| Titanium Alloy | 4.43 | 830–900 | 110–120 |

| Beryllium | 1.85 | 240–280 | 287–320 |

Conductivity and Heat Resistance

The next important properties of metals are the electrical and thermal conductivity. These have an impact on how they are used in electronics and heat exchangers.

Thermal Conductivity:

| Metal | Thermal Conductivity (W/m·K) |

| Magnesium Alloy | 156 |

| Aluminum Alloy | 237 |

| Titanium Alloy | 21.9 |

| Beryllium | 200–216 |

Electrical Conductivity:

| Metal | Electrical Conductivity (MS/m) |

| Magnesium Alloy | 22.5 |

| Aluminum Alloy | 37.7 |

| Titanium Alloy | 2.5 |

| Beryllium | 25 |

Aluminum effectively manages heat and electricity due to its high conductivity. It is perfect for effective electrical and heat transfer.

Corrosion and Oxidation Behavior

The third property for metals is corrosion resistance and oxidation behavior, which affects the reliability of metals. It is particularly crucial in harsh environments.

| Metal | Corrosion Resistance |

| Magnesium Alloy | Moderate (requires coatings) |

| Aluminum Alloy | High (natural oxide layer) |

| Titanium Alloy | Excellent (forms protective oxide layer) |

| Beryllium | Good oxidation resistance; poor in moisture or acids |

An oxide layer of protection is naturally produced by aluminum. Titanium alloys are quite resistant to corrosion, and this increases that resistance. They are hence ideal for maritime and aeronautical applications.

Lightweight Metals vs. Other Metal Types

Lightweight metals include aluminum, magnesium, and titanium alloys. They are ideal due to their low weight without sacrificing functionality. The two main reasons for this are the high strength-to-weight ratio and low density. However, the absolute strength of heavier metals such as steel, nickel, and copper is high. The choice of metal affects fuel efficiency, structural performance, and manufacturing feasibility.

Lightweight metals are necessary when reducing weight is important. They are extensively utilized in CNC machining, automotive, and aerospace.

Lightweight Vs Heavy Metals

The density of lightweight metals, such as magnesium AZ31 alloys, titanium Ti-6Al-4V, and aluminum 6061, ranges from 1.7 to 4.5 g/cm³.

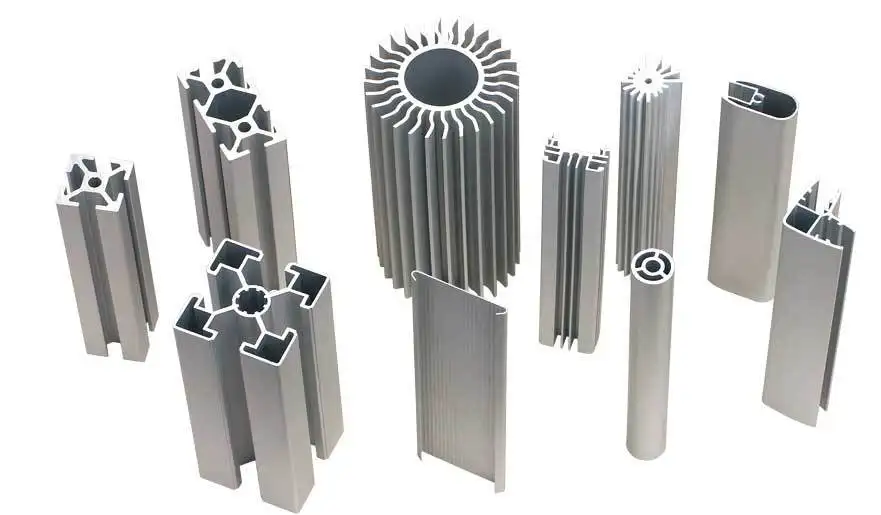

Aluminum Profiles for Lightweight Fabrication

Conversely, the concentration of heavy metals such as steel or copper ranges from 7.8 to 8.9 g/cm³. Lightweight metals are ideal for structural uses. Even though they are lighter, they have outstanding tensile strength and flexibility.

Quick Takeaway:

- Lightweight metals result in reduced weight and optimal weight-to-strength efficiency.

- Although heavy metals add weight, they are stronger and more rigid.

Lightweight vs. Non-Ferrous Metals

The majority of metals that are lightweight are non-ferrous and have little or no iron. As a result, they are naturally resistant to rust and corrosion.

- Corrosion Resistance: The alloys made of Titanium and aluminum can withstand harsh conditions.

- Machinability: It is easy to fabricate grades like aluminum 2024 and 6061. These aluminum grades also save time and money.

- Weight Efficiency: They are ideal for CNC machining, where strength is less important than weight reduction. Because of these qualities, light metals are superior to steel for applications requiring precision or rapid speed.

Why Density Matters More Than Strength

The density matters more than strength because density determines the performance. The low density has the advantages of lighter parts, better fuel efficiency, and easy assembly.

Products made of magnesium and titanium are better than steel due to superior strength per unit weight. Even lightweight aluminum alloys like 2024 and 6061 strike a good mix between corrosion resistance, machinability, and strength.

Mini Comparison Table: Lightweight vs. Heavy Metals

| Property / Metal Type | Aluminum 6061 / 2024 | Titanium Ti-6Al-4V | Magnesium AZ31 / WE43 | Mild Steel (AISI 1020) |

| Density (g/cm³) | 2.7 | 4.43 | 1.74 | 7.85 |

| Tensile Strength (MPa) | 270–350 | 830–900 | 150–250 | 400 |

| Yield Strength (MPa) | 240–290 | 800–860 | 130–200 | 250 |

| Strength-to-Weight Ratio | 100–130 | 190–205 | 140–145 | 50 |

| Corrosion Resistance | High | Excellent | Moderate (needs coating) | Low |

| Machinability / CNC Use | Excellent | Moderate | Good | Moderate |

| Common Coatings |

Anodizing, PEO PEO, |

Passivation | Conversion /PEO | None |

| Applications | Automotive, frames, aerospace panels | Aircraft, implants, high-temp parts | Robotics, lightweight housings | Construction, heavy machinery |

The raw strength of steel and other heavy metals can be higher. However, lightweight metals work better and efficiently. They provide designers greater creative latitude. They are used in advanced industrial, automotive, and aerospace industries because every gram counts.

Try Prolean Now!

What are the Other Lightest Metals Which You Should Know

Do you want to know which metals are the lightest? Low-density metals such as calcium, sodium, and lithium provide new opportunities for manufacturing. They increase the range of materials available for automotive and aerospace applications beyond titanium, magnesium, and aluminum.

Lithium: The Lightest Metal on Earth

Lithium is the lightest and strongest metal according to weight. Its low density (0.534 g/cm2) makes it ideal for batteries, energy storage, and airplanes.

Lithium and Lithium-Ion Batteries

Specialized custom CNC machining services are used to properly shape lithium. Lithium precise machining is available from ProleanTech. This guarantees robust components with precise measurements.

Advantages:

- Lithium is exceptionally lightweight and is great for minimizing the mass of the component.

- It has high metal strength in relation to weight.

- Moreover, lithium is advantageous for particular lightweight alloy CNC machining processes.

Limitations:

- Lithium is extremely delicate and reactive.

- The protective coating is also needed for safe usage.

Applications:

Lithium is used in the production of lightweight structural components for electric car batteries and aircraft electronics.

Sodium and Calcium in Lightweight Applications

Calcium and sodium are also light metals. However, they are very reactive. ProleanTech works with engineers to supervise these reactive materials’ machining processes. Selecting the lightest metals is beneficial.

Benefits when alloyed:

- Calcium and sodium are able to produce lighter metals for low-density structural elements

- They make magnesium and aluminum alloys stronger.

- They are compatible with specialized CNC machining services once stabilized

Applications:

- Applications for specialty lightweight alloys in automotive and aviation

- The lightweight heat exchangers and electronic components are also made by these lightest metals.

Rare Lightweight Alloys and Future Potentials

To develop the strongest lightweight metal solutions, certain rare alloys mix beryllium, magnesium, lithium, or titanium alloys. For applications involving rare metals, ProleanTech ensures optimal material selection, coating, and machining. PEO treatments are also used for corrosion resistance and lifespan. Their expertise allows sectors to function as efficiently as possible without compromising security.

Trends and Benefits:

- They reduce weight without compromising the strength of the metal.

- These alloys have outstanding corrosion resistance and thermal performance.

- They are enhanced for more complex CNC machining operations.

Potential Applications:

The potential applications for these alloys include very light structural elements in aerospace and defense. Moreover, the production of high efficiency engine parts for cars and ultra-light surgical tools and implants is also produced with these lightest metals.

What Makes Lightweight Metals the Smart Choice for Your Projects?

Metals that are lightweight are durable, strong, and efficient. They are a great option for many industrial applications due to these qualities. Because of their low weight, they are vital to sectors including manufacturing machinery, automobiles, robotics, and aircraft.

Weight reduction and accuracy are both necessary in these industries. Hence, advanced tools and finishing techniques are used in custom CNC machining services. It guarantees that your lightweight metal components satisfy precise design specifications.

Maximizing Strength While Minimising Weight

The high strength-to-weight ratio of lightweight metals is a major reason for their use. The magnesium alloys, titanium alloys, and aluminum 6061 provide the necessary strength. They perform very well for the manufacturing of load-bearing and structural components.

Aluminum Extrusion Profiles for Industrial Applications”

Moreover, the automotive sector is increasingly using metals like titanium alloys and aluminum to improve fuel efficiency and handling. Titanium’s strength-to-weight ratio is outstanding. It makes it possible for aircraft components to remain stable during temperature and stress fluctuations. Lightweight metals are also perfect for CNC machining because of these characteristics, which necessitate eliminating unnecessary weight while maintaining component stiffness.

Built-in Resistance to Corrosion

A lot of light metals are naturally resistant to corrosion. However, coating techniques like PEO and anodizing increase its resistance to corrosion and durability. It equips them to handle challenging working conditions.

Weight is no longer the main consideration when choosing lightweight metals. They can perform better than heavy metals thanks to improved coatings. As a result, parts had a longer lifespan and required less maintenance.

For components exposed to outdoor, chemical, or marine environments, these treatments are particularly important. They maintain the inherent mechanical qualities of the alloy while offering additional protection.

Optimised Thermal Performance

Heat causes extremely minimal expansion in certain light metals, such as copper alloys and aluminum. They are also excellent heat conductors. They are therefore ideal for cooling systems, electronic casings, and heat transfer components.

These materials maintain their dimensional stability with temperature changes as compared to heavier metals. It reduces thermal stress and deformation. These metals are ensured to retain their thermal efficiency while meeting certain design tolerances due to precision machining.

Reliable Durability and Structural Integrity

Alloys made of light metals, such as magnesium and titanium, are resistant to impact, wear, and fatigue. Despite being extremely light, they remain sturdy. They are therefore appropriate for automation equipment, engine housings, and aeronautical structures.

Tight tolerances are maintained by sophisticated machining and finishing techniques. These metals can function in challenging situations because of their surface treatments and structural stability.

Sustainability Through Recyclability

The excellent recyclability of lightweight metals is one of their main advantages. They continue to have mechanical properties. It is possible to recycle titanium, magnesium, and aluminum several times. It reduces industrial waste and energy consumption. This environmentally friendly feature lessens its influence on the environment. Engineers and manufacturers can achieve sustainable manufacturing by selecting the appropriate materials.

Lightweight Metals in Additive Manufacturing (AM)

How AM Enhances Lightweight Metal Design

Additive manufacturing allows designers to accurately create complex, lightweight metal components. AM uses materials such as lightweight aluminum, titanium alloys, and magnesium alloy products to reduce weight and waste without sacrificing strength. For high-performance industrial, automotive, and aerospace applications, lighter metals are ideal.

The ProleanTech team optimizes designs for the best strength-to-weight ratio, guaranteeing that every component meets exacting criteria.

CNC vs. AM: Choosing the Right Process

CNC machining is the most effective method for producing high-precision components with precise tolerances. AM is excellent at complex geometry, internal structures, and quick prototyping.

Precision-machined lightweight metal parts

ProleanTech offers custom CNC machining services and AM solutions in two ways. The company selects one that meets the needs of your project. By using the appropriate technique, engineers can produce robust, lightweight metal components while saving time.

Surface Finishing & Coating in AM Components

For lightweight metals, surface quality and durability are essential. Modern coatings like PEO and anodizing increase thermal performance. They also improve resistance to corrosion and wear.

This makes it possible for aluminum and titanium alloys that are lightweight to perform similarly to heavier metals. They function well while maintaining their modest weight. Advanced surface treatments are applied to AM components by ProleanTech. This gets parts ready for difficult circumstances.

Advantages and Disadvantages of Lightweight Metals

Benefits of Lightweight Metals in Modern Design

- Reduced weight: The key benefit of the reduced weight improves fuel efficiency, handling, and structural flexibility of the part.

- High strength-to-weight ratio: The metals that have a high strength-to-weight ratio include lightweight aluminum, titanium alloys, and magnesium alloys. They are ideal for use in aeronautical, automotive, and industrial settings.

- Corrosion resistance: The non-ferrous metals and coated alloys are impervious to oxidation and wear.

- Machinability: Alloys such as aluminum 6061 and 2024 vs. 6061 are easily processed by CNC machining.

- Sustainability: Most of the light metals are recyclable without sacrificing their properties.

Limitations and Safety Concerns

- Certain metals are extremely reactive, such as alloys of magnesium and lithium. To be safe, they require protective coatings.

- Titanium and beryllium alloys are more expensive and more challenging to work with.

- Surface degradation and corrosion can occur in the absence of coatings such as PEO or anodizing.

- Appropriate design and material management are essential for longevity and safety.

How to Choose the Right Lightweight Metal for Your Needs

Coatings & Surface Treatments

When choosing a lightweight metal, consider coating compatibility and surface treatment options. Anodizing and PEO increase the durability of lightweight aluminum, titanium, and magnesium components. Additionally, they increase resistance against corrosion. ProleanTech ensures that parts are designed with strength, weight, and protection in mind.

Evaluating Mechanical Properties

The characteristics of a metal demonstrate how it handles load, stress, and repeated use depends upon its mechanical properties. Tensile strength, fatigue resistance, and hardness characteristics are the most important elements. The kind of alloy, heat treatment, and processing technique all affect them. Offering distinctive CNC machining services is supported by these insights.

Assessing Thermal Behaviour

Heat-sensitive components must have high thermal conductivity. Despite its great strength, titanium has low heat conductivity. On the other hand, aluminum alloys conduct heat quite well.

High-quality aluminum components

Weight: The Critical Factor

Fuel efficiency, handling, and structural design are all improved by weight reduction. Component weight can be significantly reduced by using light metals like magnesium and lithium alloys.

Importance of Corrosion Resistance

Non-ferrous, lightweight metals resist corrosion better. With the correct coatings, even reactive metals like magnesium may survive harsh environments.

Budget & Cost Implications

Selecting the ideal lightweight metal requires a balance between performance and cost. Titanium and beryllium are expensive choices. They cost around $30–40/kg and $800–1,000/kg, respectively. They are utilized in electronics, defense, and aerospace because of their exceptional strength and heat resistance. Aluminum alloys provide a great mix of strength, weight, and cost. They range in price from $2 to $3/kg. They are used in consumer goods, automobiles, and airplanes.

Magnesium alloys are even lighter, about $4–$5/kg. Magnesium alloys require coating to prevent corrosion. They function well in portable electronics and automobiles. To put it briefly, each metal meets a certain demand, such as high-end performance vs cost-effective efficiency.

Matching Manufacturing Methods

Choose a process that is suitable for the design and metal:

- The CNC machining procedure: Outstanding precision, ideal for aluminum alloys.

- Manufacturing by addition: Additive manufacturing produces complicated forms and lighter components.

These methods are used by ProleanTech to create high-quality, lightweight metal components that work well for any kind of application.

Lightweight Metal Alternatives Worth Considering

Composite Materials Explained

- Composites are lighter alternatives to metal that work better when two or more components are combined.

- They are increasingly being used in aircraft, automotive, and industrial components, where it is crucial to reduce weight.

- Capable of accommodating advanced manufacturing methods like CNC machining

Carbon Fiber Reinforced Options

- The strongest and lightest metal alternatives are carbon fiber reinforced composites (CFRP).

- Despite being much lighter than titanium or aluminum alloys, they are incredibly strong and stiff.

What Makes Carbon Fiber Unique

- Superior strength-to-weight ratio compared to the majority of lightweight metals, resists corrosion and thermal expansion.

- Ideal for high-performance applications when lighter metals are unable to meet design standards

- CNC custom services work well with precision parts

Try Prolean Now!

Future Trends in Lightweight Metal Technology

Aluminum-Lithium and Titanium-Aluminide Alloys

- Aluminum-Lithium alloys are perfect for the automotive and aerospace industries because they increase rigidity and save weight.

- Titanium-aluminide alloys outperform conventional lightweight metals by combining low density and high thermal strength.

Metal Additive Manufacturing for Lightweight Components

- By using less material to create complicated structures, additive manufacturing maximizes the strength-to-weight ratio.

- Works well with goods made of magnesium alloy, titanium alloy, and lightweight aluminum for accurate CNC machining process integration.

Metal-Matrix and Hybrid Composite Innovations

- For increased fatigue resistance, metal-matrix composites blend lightweight metals with ceramics or carbon fiber.

- Hybrid designs improve corrosion and wear performance while producing the strongest and lightest metal solutions.

Emerging Lightweight Metals / Next-Gen Alloys

- In order to accomplish severe weight reduction, next-generation alloys concentrate on coated magnesium, titanium-aluminide, and aluminum-lithium.

- PEO and other advanced surface engineering improve fatigue life, corrosion resistance, and durability.

- Ultra-light, high-performance components are made possible by the combination of surface treatments, additive manufacturing, and new alloys.

Why Choose ProleanTech for Lightweight Metal Projects

custom CNC machining services for lightweight metals are ProleanTech’s area of expertise. They specialize in aluminum grades, titanium alloys, and magnesium alloys.

- Precision & Performance: They provide parts that meet precise weight and metal strength requirements.

- Advanced Surface Engineering: Your components have better corrosion resistance, wear performance, and lifespan thanks to PEO coatings and anodizing.

- Wide Material Knowledge: They help you choose the best option, whether it’s next-generation alloys, lightweight steel, or aluminum.

- End-to-End Support: ProleanTech guarantees dependability and effectiveness from the initial design consultation to the last CNC machining procedure.

Partnering with ProleanTech means your project will gain from the most robust lightweight metal solutions, cutting-edge coatings, and accurate production that are all tailored for longevity and performance.

Take the Next Step:

Maximize efficiency and quality for aerospace, automotive, and industrial designs with ProleanTech.

Final Thoughts

Choosing the right lightweight metal depends on balancing weight, metal strength, machinability, and corrosion resistance. The next generation of high-performance lightweight components is being shaped by innovations such as PEO coatings, hybrid composites, titanium-aluminide, and aluminum-lithium. For high-performance projects and specialized CNC machining services, ProleanTech’s experience guarantees the best material choices.

FAQs

Q1: What are the top 5 lightest metals?

The top five metals are Aluminum, Lithium, Magnesium, Beryllium, and Titanium.

Q2: What metal is lightweight but strong?

The lightweight but strong metals are Aluminum 2024 vs 6061, Magnesium AZ31 alloys, and Titanium Ti-6Al-4V alloy products.

Q3: Are there any metals lighter than water?

Yes. The densities of lithium and some magnesium alloys are lighter than water.

Q4: What is a lightweight silver-like metal?

The alloys made of titanium and aluminum give off a silvery look while being lightweight.

0 Comments