Mass production

The large-scale manufacture of standard products with streamlined processes and specialized machinery is more commonly termed mass production. It means continuous or repetitive fabrication of goods where each worker or machine is engaged in one specific action, like using assembly lines.

It helps manufacture such goods in huge quantities at reduced unit cost and with minimum human effort. The divisibility of labour with the integration of automation technology generates the centre around which mass production evolves.

Manufacturing becomes organized into discrete steps, with each optimized for speed and precision, all simultaneously, making it possible to produce in real time and have consistent quality. Proleantech has been a mass production partner for many companies across the globe through our easy re-order process and short lead times. Using interchangeable parts and standardized components makes final assembly efficient and scalable at our machine shop.

Historical Impact of Mass Production

Mass production originated in the 18th-century Industrial Revolution, when advancements in machine tools and mechanical equipment for textile processing made producing goods in large volumes possible.

British engineer Henry Maudslay, developer of the precision screw-cutting lathe, was instrumental in standardizing parts, which are essential in mass production.

The concept gained traction rapidly in the United States. By the early 20th century, when textile industries changed into mass production and armaments production, the idea reached a very wide horizon.

During World War II, the production of large amounts of military equipment, such as the main battle tank, provided the impetus to adopt automated assembly line technology and flow production techniques.

The war proved to many how mass production could attain the capacity for global demand, thus rebuilding the economies and labor scenarios worldwide.

Mass Production in the United States and Its Evolution

Assembly line with identical parts on different tracks

A new era of mass production began in the United States in the early 1900s. Henry Ford, founder and owner of Ford Motor Company, changed the face of the automobile industry with the introduction of a moving assembly line in 1913.

This development slashed the time to produce a Ford Model T from 12.5 hours to a mere 1.5 hours, driving costs down and putting cars within reach of the average American.

Ford’s Highland Park, Michigan, assembly plant became a model for modern manufacturing. Its fast conveyor belt allowed parts to flow endlessly between workstations. There was practically no waiting time for tools between operations, thus maximizing output.

Other manufacturing sectors like consumer electronics, food processing, and defense then adapted this model.

After World War II, the United States expanded its production system to include automation technology and computerized control systems. The American manufacturing industry is still working to perfect these mass production methods. It uses real-time data, validation testing, and robotics to keep itself up to date with the global market.

Henry Ford’s Role in Mass Production

The contribution of Henry Ford to mass production includes the line itself. He championed the principle that mass production must produce “products for the masses,” involving everyone’s affordability, efficiency, and standardization.

Ford could engineer all aspects of production, from raw material sourcing to final assembly, by focusing on a very particular product, the Ford Model T, which enabled him to do so by looking at a single product.

The cost of labor is reduced by the division of labor, and the mechanism of specialization would increase the intensity of production. And this concept of low volume manufacturing became Fordism, which to this day serves as the route toward industrial development in the whole world.

The Ford assembly line remains a novel concept, signifying how engineering principles can transform the very economic and social landscapes.

What Is the Definition of Mass Production?

Mass production is defined as manufacturing products in large numbers, usually identical, by entirely automated or semi-automated processes. Among other things, such production generally involves:

- Assembly and flow production lines

- Interchangeable and standard components

- Division of labor among specific tasks

- Automation technology reduces manual effort

- Economies of scale reduce the unit costs

This type of production is most beneficial for the kind of products that have some steady demand with very little variation in design.

Try Prolean Now!

Mass Production vs. Mass Manufacturing

While the terms are often used interchangeably, there are subtle distinctions:

| Aspect | Mass Production | Mass Manufacturing |

| Focus | Process efficiency and volume | Organizational scale and infrastructure |

| Scope | Specific product lines | Entire manufacturing ecosystem |

| Examples | Ford assembly line, conveyor belt systems | Global factories producing multiple SKUs |

| Optimization | Task-level and line-level | Enterprise-level and supply chain-wide |

Mass manufacturing encompasses mass production and expands beyond to include logistics, supply chain management, and enterprise resource planning.

What Is Mass Manufacturing?

Mass manufacturing refers to the large-scale production of goods using standardized processes across multiple facilities. It integrates mass production techniques with broader organizational strategies, including:

- Global sourcing of raw materials

- Automated assembly line production

- Real-time monitoring of production volume

- Standardized product requirements documentation

It is the backbone of modern industrial economies, enabling companies to produce goods at scale while maintaining quality and cost control.

Understanding Mass Production and Mass Manufacturing

Together, they enable the production of large numbers of standardized products with optimized unit costs and minimal waste.

Mass manufacturing and mass production are symbiotic things, where the former provides the technical foundation – assembly lines, machine tools, and automation- and, in the latter’s case, orchestrates all elements across global operations. Together, they enable mass production of many identical units at the optimum unit cost and with little wastage.

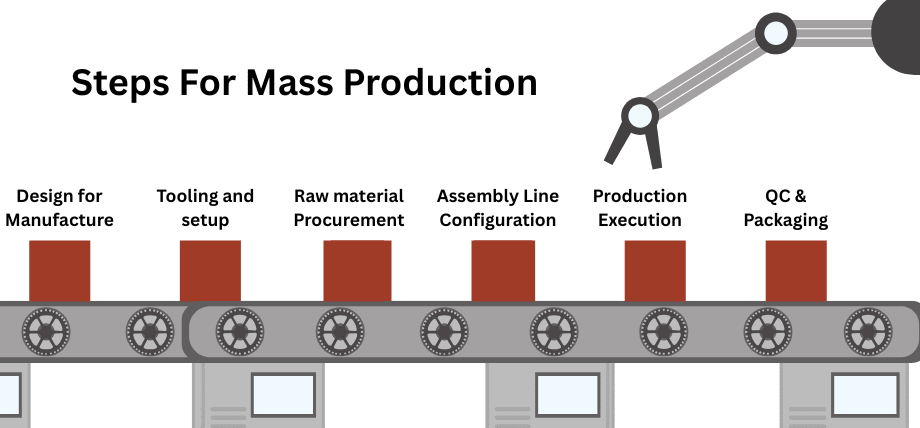

How Mass Production Works: Process Steps

Mass production seps

The typical mass production process follows these steps:

- Design for Manufacture: Design engineering teams would optimize the product design for manufacture.

- Tooling and setup: Specialized machines and jigs are set up for the production tooling.

- Raw material Procurement: Bulk sourcing of standard materials to lower costs.

- Assembly Line Configuration: Conveyor belts and workstations arranged for sequential operations.

- Production Execution: Automatic or manual tasks are carried out in real time.

- Quality Control and Validation Testing: Detecting defects and validating processes ensures that products meet the required standards.

- Final assembly and packaging: Products are complete and ready for distribution.

This customized process can be continuous or batch processing, flexible, depending on the requirements for the product.

Try Prolean Now!

Mass Production vs. Other Production Methods

Below is a table to summarise mass production.

| Method | Description | Pros | Cons |

| Mass Production | Large quantities of standardized products | Low unit costs, high efficiency | Low flexibility, high initial investment |

| Batch Production | Groups of products are produced in cycles | Moderate flexibility, good for seasonal goods | Setup time, higher per-unit cost |

| Custom Manufacturing | Tailored products for specific clients | High customization, premium pricing | Low scalability, high labor costs |

| Job Shop | Small-scale, varied production | Ideal for prototyping and niche markets | Complex planning, limited throughput |

Each method serves different market needs and product types.

Difference Between Mass Production and Batch Production

Mass production is continuously optimized for scale, while batch production runs only for certain cycles. As much as it allows product changes between batches, mass production goes for uniformity.

Difference Between Custom Manufacturing and Mass Production

Custom manufacturing is when products are tailored to the most individual needs and often designed to be coupled with intense amounts of manual labor requiring special skills. At the same time, mass production depends on uniform parts of an automated assembly line to get goods for as many people as they need within a certain time.

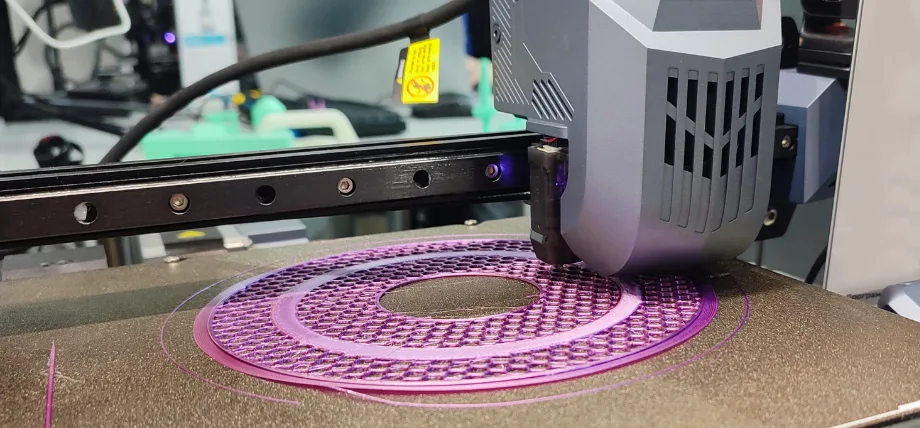

Mass Production vs. Prototyping

3D printing a prototype

Prototyping has evolved as the stepwise development of a product before its full-scale availability to customers. Concepts are subjected to tests, trying out different types of materials and functionality. This is all preceded by the validation and optimization for manufacturability before mass production starts.

Difference Between Mass Production and Job Shop

Machine shop

Job Shops are busy with schedules as general specifications for different orders in small quantities, which are very different from each other. They use general-purpose machines and skilled labor.

Mass Production, on the other hand, uses specialized machinery and standardized methods to produce large volumes of identical products.

What Mass Production Parts Are Made by Industries?

Among the most common components and products that are being mass-produced by industries are:

- Automotive: Engine blocks, transmissions, brake systems.

- Electronics: Display panels, connectors, circuit boards.

- Aerospace: Turbine blades, fuselage, avionics.

- Consumer Goods: Fasteners, plastic housings, packaging.

- Defense: Ammunition, armour of the vehicle, and communication equipment.

These sections are, in many cases, fabricated on automated assembly lines and are tested under strict testing procedures.

Technologies in Mass Production

The contemporary mass production is based onhighe technologies:

- Automated Assembly Lines: Conveyor belts and robots in production.

- CNC Precision Machining: Technological manufacture of standardized components.

- Injection Molding: Large volume manufacturing of plastic components.

- 3D Printing: Low-volume and rapid prototyping.

- Industrial IoT (IIoT): Real-time control of the equipment and processes.

- Machine Vision Systems: Quality control and defect inspection.

These technologies offer low labor costs, increase consistency, and make production continuous.

Cost Comparison of Mass Production and Batch Production

Below is a table that can help you compare the cost of mass production and batch production:

| Alt: Photo of a metal machine shop with many workstationsCost Factor | Mass Production | Batch Production |

| Setup Costs | High initial investment | Moderate setup costs |

| Unit Costs | Low per unit | Higher per unit |

| Labor Costs | Lower due to automation | Higher due to manual tasks |

| Flexibility | Low | Moderate |

| Scalability | High | Limited |

Mass production is more cost-effective for large quantities, while batch production suits variable demand and smaller runs.

Custom CNC Machining for High Volume Production

Proleantech provides tailored CNC machining solutions for your tooling, prototyping, and scaled productions. We excel in DFM and provide prototypes for high-volume production in the shortest time. Contact us today!

Conclusion

Through the use of standardized elements, labor division, and the development of the latest technologies, such as CNC manufacturing, IoT, and robotics, mass production is becoming an important factor in economic growth and fulfilling the global demand.

Although it is superior in terms of scalability and cost effectiveness, its inflexibility is opposite to the flexibility of batch production, custom production, and job shops, which have different market demands.

With the fluctuating consumer needs and technological innovations in the industries, one of the main pillars of industrial development lies in mass production that balances efficiency, quality, and affordability to provide products to the masses.

0 Comments