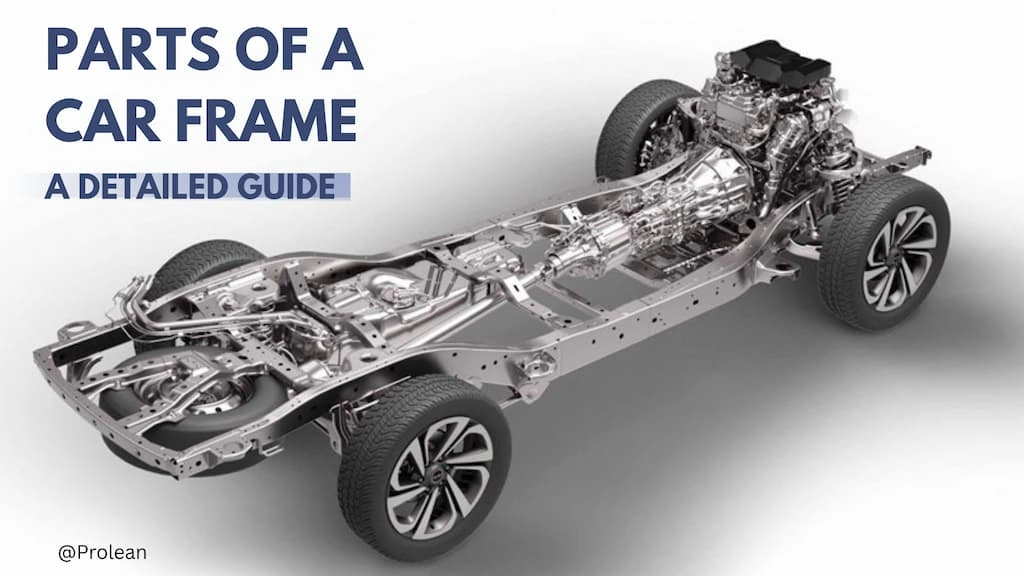

parts of a car frame

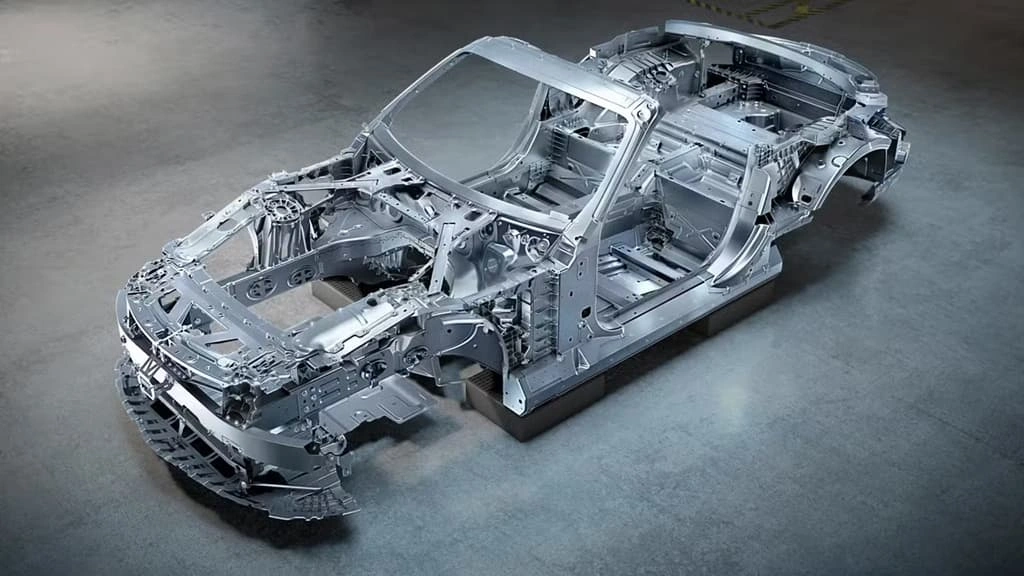

Do you know how a car supports the weight of its components and passengers? A structural frame is responsible for this. It maintains vehicle geometry, provides mounting points for components, and contributes to crash safety. The frame itself involves the assembly of different individual components, like the frame rails, suspension mounts, and axles.

Understanding different parts of a car frame, frame types, and material options can help you ensure the desired quality and functional requirements. So, let’s elaborate on these one by one.

What is a Car Frame?

The car frame is the basic foundational skeleton of the car, which acts as the main load bearing structure. It provides support and stability to the car body, and is typically made with high-strength materials like steel and alumiunum alloys. Often, people confuse the car frame with the chassis; they are closely related but not identical. Unlike a frame, a chassis includes all the supporting systems attached to the frame.

Car frame

Furthermore, the frame contains mounting features at fixed positions to assemble different car components, such as suspension, exhaust system, engine,and axles. Meanwhile, the car frame construction involves I beams, H beams, C channels, box sections, cross members, rails, sheet metal parts, etc.

If we look at history, it was the continuity of the horse-drawn carriages while scientists made the first car. In the early 1800s, wooden structures and iron bracket joints were used. Then, it is continuously evolving and modern high-performance chassis what we have today.

Types of Car Frames

Based on the shape and geometry, there are four types of frames: Ladder, monocoque, tubular space, and backbone frames. Each of these has a distinct set of advantages and limitations.

Let’s briefly discuss the types of car frames one by one.

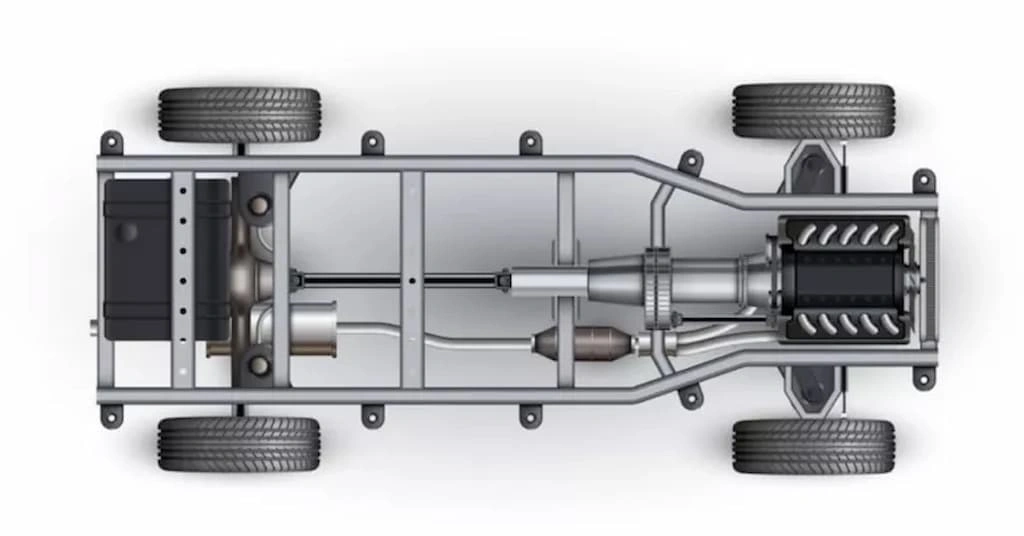

1. Ladder Frame Structure

Ladder frame

This type of car frame resembles the shape of a “ladder”, two parallel rails connected by smaller ones. The symmetrical geometry provides greater stability and is easy to construct. Ladder frames are mainly found in Off-road and passenger cars. It allows mounting/joining various integral car components.

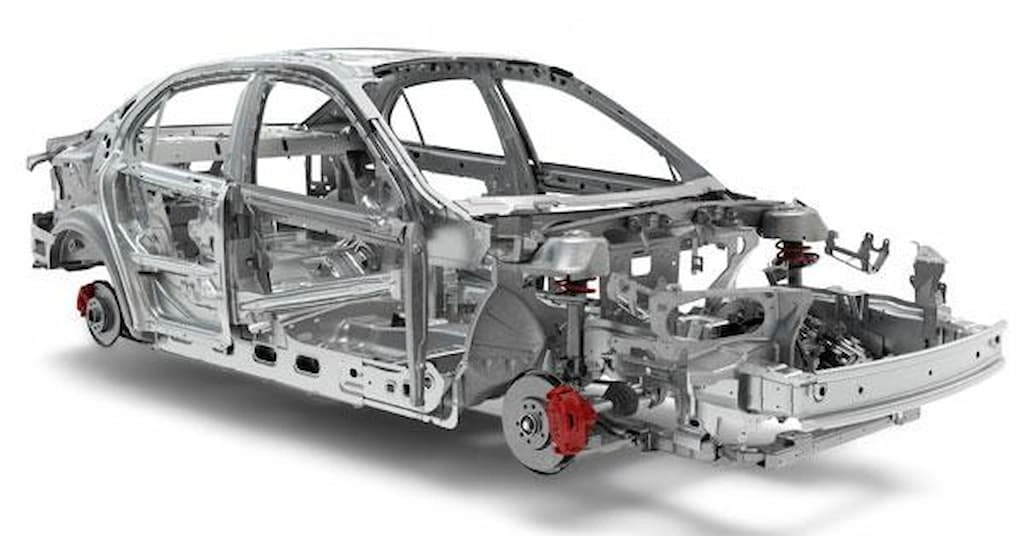

2. Monocoque Frame Structure

monocoque frame

A monocoque frame is a cohesive structure that combines the frame and body. This compact design is popular in passenger buses, VANs, and cars. The synchronization of frame and body provides better load balance due to improved assembly accuracy.

Consequently, it also helps in weight optimization of the car and better aerodynamics. Consequently, the unibody construction makes the car quieter and also provides higher strength during crashes. The downsides of monocque frames are that they are expensive and difficult to repair.

3. Tubular Space Frame

Tubular frame

As the name suggests, the tubular steel pipes form the desired frame construction. The majority of the joints are permanent and created by welding. Tubular chassis frames are typically used in custom racing cars. They are lightweight and provide a higher strength-to-weight ratio. However, it is challenging to construct them due to design complexity.

4. Backbone Frame

It is a type of car frame that resembles a “backbone” with a central tubular structure, connecting front and rear suspension, engine, and drivetrain components. Unlike a ladder or a monocoque, it relies on the central tube for rigidity and load distribution instead of side members.

Try Prolean Now!

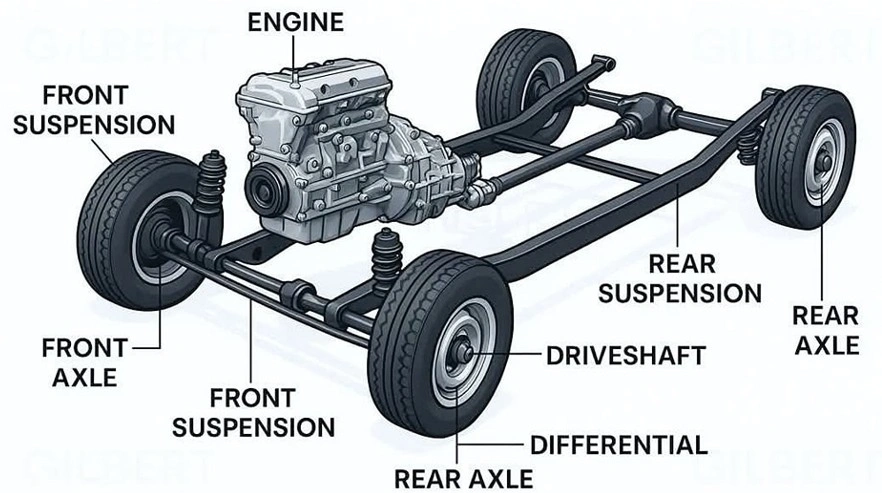

What Are the Different Parts of a Car Frame?

car frame parts

A car frame consists of different parts and systems. Some are primary building blocks, and others are installed later on the frame. This includes frame rails, cross members, side frames, floor frames, braking system, suspension system, and universal joint.

Let’s discuss more.

1. Frame Rails and Cross Members

Frame rails are the longitudinal beams, like I or H beams. Meanwhile, cross members are similar structural elements connecting the longitudinal rails. You can consider them as the main load-bearing structures in the frame. Consequently, the side rails also provide mounting features for transmission, axles, and sub-system enclosures.

2. Bulkhead and Front Side Frame

A bulkhead refers to the vertical partition at the car front frame, separating the engine bay from the passenger cabin for rigidity and safety. Another function is providing support and mounting features for front-end car parts. On the other hand, the front side frame is the main structural rail extending forward from the bulkhead.

3. Floor Frame

It forms the flat base of the cabin area, integrating crossmembers and panels. The main function of the floor frame is to support seats, passenger loads, and improve torsional stiffness.

4. Suspension System

The suspension system is an integrated component with the car frame that connects the wheels to the car body to achieve driving stability and comfort. It is mounted on the front and rear ends of the frame. The shock absorber and springs balance the car’s position when the tyre touches an uneven road.

5. Steering System

The steering system controls the front wheel movement for direction. It is attached to the frame at the front section. Steering column above the bulkhead, steering rack across the front cross member, and steering linkages to the front wheel hub.

The steering system can be hydraulic or electronic. A hydraulic system uses fluid pressure, whereas electronic systems use motors to reduce effort and increase directional accuracy.

6. Clutch and Transmission System

Clutch controls the engagement of the crankshaft with the transmission system; hence, they are directly related to each other. In simple terms, the clutch makes the gear shift possible in the car. On the other hand, the transmission system increases or decreases the RPM.

As the gear ratio increases, the transmission output goes higher. Meanwhile, the transmission mounting can be placed in the floor frame or inside the floor tunnel.

Further interested in the engine and transmission system, read about the camshaft here.

7. Braking System

Braking systems are used to stop or slow down the car’s speed, and are mounted to the structural frame. Typically, disc or drum brakes are used in vehicles. Although they have different capabilities, both of them apply friction to tackle the rotational energy of wheels.

8. Rear Axle

The rear axle could be enclosed as a live axle assembly or as separate shafts. Function-wise, it supports rear-wheel loads and transmits drive torque to the wheel. Consequently, axles can be designed to fall under regular suspension or independent suspension.

9. Universal Joint

A universal joint connects the front axle driveshaft and transmission shaft, supporting their alignment and smooth power transfer. The angled position of the U-joint allows for correcting any angular misalignment caused by suspension movement.

10. Sear Mounts

These are the features in frames to secure car seats strongly. They are attached to the frame and restrict any movement of the seat while riding the car, providing both seat stability and crash safety. Furthermore, frames can also include the custom mounts that support interior parts.

11. Engine Mount

It is one of the critical sections of the car frame that secures the engine. An engine mount can have rubber or hydraulic support to reduce vibration and uniformly distribute the load.

12. Crush Zones

The crush zone is for absorbing the impact force when a car collides with other vehicles or objects. These zones are the car’s rear and front sections, made with strong and thick metal bars.

If you are interested in other car parts, you can read about the motor shaft here.

Try Prolean Now!

Materials for Car Frame Parts

It is important to use the right material to make parts of a car frame, so the car can deliver the desired stability, performance, and durability. However, the choice of material depends on the strength & weight requirements, cost, and other factors.

High-strength materials like aluminum alloys, steels, magnesium alloys, and carbon fiber can be used according to your requirements.

Aluminum alloys provide a lightweight yet corrosion-resistant option. It helps to reduce vehicle weight and improve fuel efficiency. Another popular choice is steel, which provides advanced toughness, crash resistance, and cost-benefit.

Furthermore, magnesium alloys and carbon fibre are chosen for specialized or high-performance cars. Magnesium alloys are among the lightest structural metals that can help to reduce frame weight and improve handling. Although being expensive, carbon fiber significantly improves the strength-to-weight ratio and stiffness.

Low-carbon / Mild Steel

It is a low-cost alloy for car frames with excellent formability, ductility, toughness, good weldability, and machinability. Low-carbon & mild steels are suitable for rails and cross members.

Stack of rolled Mild Steel 1018

Grades: AISI/SAE 1008–1018, 1020

HSLA Steel

HSLA Steels provide a better strength-to-weight ratio than low-carbon alloys. They are also good in fatigue performance, cold formability, corrosion resistance, and weldability. You can use these materials for thinner and lighter subframes.

High-Strength Low-Alloy (HSLA) Steel Coil

Grades: HSLA-350, HSLA-420

Aluminum Alloys

Aluminum alloys are known for their excellent strength-to-weight ratio, corrosion resistance, and formability. Some car frame parts can also be made with the aluminum extrusion method.

Aluminum Alloys

Grades: 6061, 6063, 7075, 6005A, etc.

Magnesium Alloys

Magnesium alloys are used for weight reduction while maintaining high specific stiffness and light weight. However, they have low ductility and some joining limitations.

Magnesium ingots

Grades: AZ91, AZ31, AM50, AM60

Carbon-fibre (CFRP) Material

Some high-performance and low-weight cars also use composite materials like carbon fiber. They provide exceptional specific strength, stiffness, corrosion resistance, and good fatigue life. However, CFRP could be costlier.

Grade: Prepreg, RTM laminates, SMC/UD tapes

Manufacturing Processes for Car Frame Parts

The raw materials (Metal, alloy, or composites) are converted into functional frame parts by various manufacturing processes, including CNC machining, die casting, and sheet metal work.

CNC machining offers high precision and complexity, die casting produces strong and lightweight parts, and sheet metal is ideal for large and flat items used in frames.

CNC Machining

CNC machining of the car frame

CNC machining involves processes like milling, turning, and drilling with distinct setups and tooling. They precisely remove the material from the workpiece and create the designed shape/geometry.

Typically, high-precision frame parts like suspension brackets, engine mounts, and custom frames are made with this method. It is also a prominent method for prototyping.

This manufacturing process suits low-to medium volume production where customization and tolerances are critical. Otherwise, it can be costly and time-consuming.

Die Casting

Die cast rear arm

This manufacturing method is highly favourable for high-volume production of automotive components, including frame parts. Aluminum or magnesium alloys are used in the process, which involves injecting liquid metal into the die cavity. The molten metal solidifies inside the die and obtains the designed shape.

Die casting can make several parts of a car frame, such as crossmembers, subframes, and the steering column housing.

Sheet Metal Work

CNC machining of the car frame

The sheet metal fabrication involves various metal forming techniques like bending, stamping, blanking, punching, welding, and riveting. A raw metal sheet is cut into a suitable size & geometry, and formed into a frame part. The process might also need assembling multiple parts with rivets and welding. Consequently, techniques like stamping and blanking need a die and punch setup.

Some examples of car frame parts made with sheet metal are large and flat items, such as door panels, roof sections, floor panels, and wheel housing.

Do You Need Custom Car Parts? Contact ProleanTech

The quality and cost of car parts heavily depend on your automotive frame design and the capabilities of your manufacturing partner. If you are looking for an experienced and reliable custom parts manufacturer, ProleanTech can be your best choice.

We have more than a decade of experience producing car parts for many local and international brands. Our advanced die-casting, sheet metal fabrication, and multi-axis CNC machining services can meet your specific needs. Importantly, we have strict quality control to meet the industry standards.

Moreover, the process of ordering parts is simple and streamlined in every stage, from how you get a quote to post-processing and packaging. We are also flexible in production volume and lead time.

If you have any further doubts, contact us now.

Conclusion

The car frame is the backbone of the vehicle’s structure and safety. It provides stability and supports other car systems and sub-systems. There are different types of frames for you to choose from. You can make a decision according to the car type and the load it will carry.

You must choose the right material and manufacturing process to produce high-quality car parts at a reasonable cost. Then, it is equally important to choose a reliable and experienced manufacturer.

FAQs

What are car frames made of?

Car frames are usually made with high-strength steel and aluminum alloys. In some racing cars and EVs, carbon fiber composites are also used.

What are the parts of a car frame called?

Some parts of a car frame are the longitudinal rail, the cross member, wheel housing, axles, suspension components, and steering mounts.

What parts make up a chassis?

A chassis involves a structural base and its integrated mechanical systems, including floor panel, suspension, axles, steering linkage, brake mount, and body mounting points.

How expensive is it to replace a car frame?

Being a critical structural component of a car, it is expensive to replace compared to general repair work. The exact cost can vary depending on car brand & model, frame type, and labor charges.

What is a chassis vs frame?

Chassis is a fundamental structure over which other systems are mounted and the body is built, whereas chassis is a broader structural framework of a car that combines frames and other systems; drivetrain, brakes, suspension, steering, etc.

0 Comments