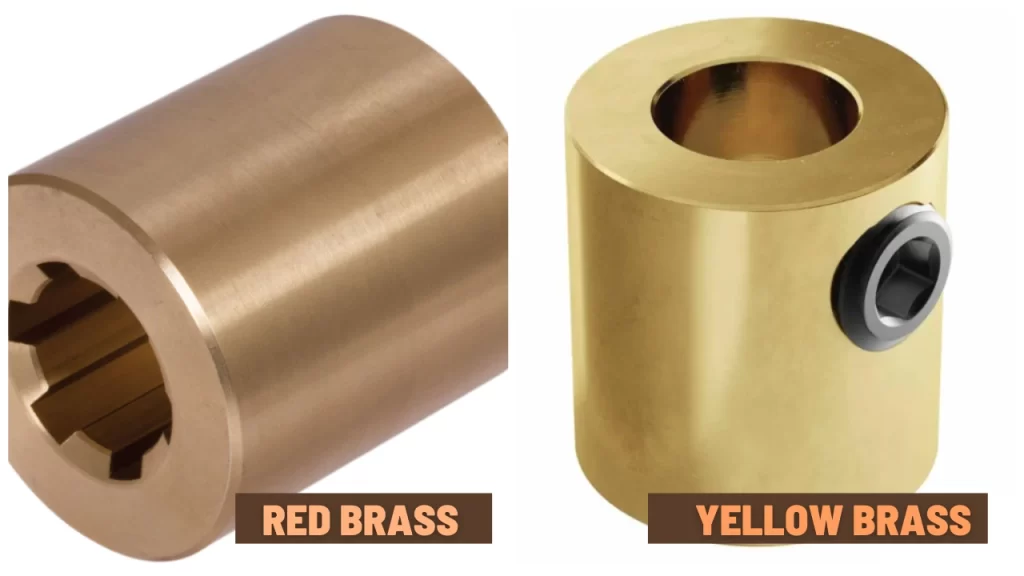

Red brass vs yellow brass

Brass, an alloy of copper and zinc, is very versatile. This versatility is evidenced by the availability of different grades of the alloy derived from the variation of constituent elements. Red brass and yellow brass are rightfully some of the most talked about grades. They are so instrumental in today’s manufacturing space that the red brass vs yellow brass comparison is prominent.

Customers often wonder what elements or characteristics differentiate the two metals. These two types of brass have distinct properties, ranging from strength to corrosion resistance and appearance to workability.

While red brass contains copper and zinc at approximately 85% and 15% respectively, yellow brass is at 67% and 33% respectively. Talking of appearance, red brass is distinctively red due to the high copper content while yellow brass has the copper color diluted by the higher zinc content.

As the alloying percentages suggest, red brass is more corrosion resistant and stronger. However, it is less machinable than yellow brass, a critical factor when looking to achieve tight tolerances. These are just some of the interesting comparisons for these two metals.

We have unpacked more differences in the next sections of the article, so read on.

What Is Red Brass?

Red brass refers to an alloy with high copper content and zinc, plus traces of tin and lead. Specifically, this alloy contains approximately 85% copper and 15% zinc. This composition makes the brass highly corrosion resistant.

For this and other properties, red brass is one of common metals in CNC machining circles by ProleanTech-your customs parts manufacturing partner. It is easy to machine and also performs well in damp environments.

It is especially excellent at warding off dezincification, which is a corrosion phenomenon that singles out zinc for leaching. As mentioned earlier, this brass type is redder than the rest due to its high content of copper.

Red brass

If the copper content is slightly reduced, the more expensive brass is called semi-red brass. You can find red brass machined components in marine components, plumbing fixtures, and pump parts, among other applications.

Chemical Properties Of Red Brass

The high copper content in red brass contributes to superior chemical properties, which are characterized by chemical stability, corrosion resistance, non-magnetism, and dezincification resistance.

Copper in red brass creates a protective layer that prevents relentless corrosion and tarnishing, a property that is further enhanced by the tin component. While the material can react in strong chemicals, it is largely stable in mild chemical environmments.

These chemical properties make red brass an ideal material for moist environments, even those that are mildly chemical in nature.

Physical And Mechanical Properties Of Red Brass

On mechanical properties, this material presents good performance, a testament to its suitability for fittings and some other demanding applications. The most notable of these properties are good machinability, reliable strength, and good wear resistance.

It means that red brass is easily machined into suitable parts for relevant industries. Moreover, the metal is castable and formable, meaning that there are alternatives or complementary processing technologies to CNC machining.

CNC machined red brass part

Talking of physical properties, this brass has a relatively high melting point of around 900°C. Adding that to the fact that it has excellent electrical and thermal conductivity means that there are many specialized projects where to use this reddish material.

Common Applications Of Red Brass

A renowned property of red brass is within the plumbing circles and it is about the material’s unmatched durability. Durability combined with machinability and versatility for different environments makes the brass suitable for plumbing and these other applications.

- Pump impellers and housings in marine industry

- Valves

- Decorations

- HVAC systems

- Oil and gas systems

Red brass refrigerator part

Advantages Of Red Brass

The advantages of red brass include;

- Requires less maintenance

- High aesthetic appeal

- Excellent strength

- Excellent electrical and thermal conductivity

Disadvantages Of Red Brass

- Higher cost

- Health concerns due to lead content in some red brass

- Cold workability is less effective

What Is Yellow Brass?

Yellow brass is a popular copper zinc alloy in cold or hot formed items and contains approximately 60-67% copper and 33-40% copper. This alloy is bright yellow in color, hence the name. There are also trace amounts of tin and lead in the brass.

Yellow brass

Like red brass, yellow brass is also common in CNC machining processes because it has various applications. Manufacturers sometimes call this alloy cartridge brass or C26000. They use it for many applications where its golden look, good workability, and strength are useful.

The lower copper content is one of the highlights of yellow brass, and this also contributes to the subdued redness. The combination of chemical components gives the material a balance of mechanical properties that make manufacturing relatively easy.

Try Prolean Now!

Chemical Properties Of Yellow Brass

Again, it is the zinc content level that defines the chemical properties and behavior of this brass alloy. Dezincification, a corrosion type that is common in brass items, is a big challenge in yellow brass.

Yellow brass dezincification

The corrosion resistance in the metal may not be enough to fight off the effect in wet applications, so using it in dry environments is the best option. Yellow brass is seen to react mostly with chloride-based acids, a fact that is useful when considering it for mechanical and related projects.

Physical And Mechanical Properties Of Yellow Brass

Like red brass, yellow brass is malleable and ductile, thus useful in forming jobs. The metal is CNC machinable, and the resulting parts are wear resistant and strong. Don’t expect the same strength as that of red brass, but you can still use the metal for fittings and comparable parts.

A noteworthy characteristic is the decorative value of the bright yellow color of the metal, which is popular in architectural projects. This property blends well with good electrical and thermal conductivity.

Architectural yellow brass

Common Applications Of Yellow Brass

Yellow brass shines, has some good level of strength, and resists corrosion to some extent. Its thermal and electrical conductivities are very good. These and other characteristics support usage in the following areas:

- Architectural items

- Electrical connectors and terminals

- Artwork and jewelry

- Plumbing faucets and fittings

Yellow brass tap

Advantages Of Yellow Brass

The advantages of yellow brass are;

- Relatively cost-effective

- More available in the market

- Relatively easy to CNC machine

Disadvantages Of Yellow Brass

These are the shortcomings of this alloy:

- Less chemically stable than red brass

- Reduced hardness and strength

- Less corossion resistance

Difference Between Red Brass And Yellow Brass

If you have ever machined alloys, leave alone copper alloys, you may have noticed that every alloy is distinct. We have also highlighted the advantages and disadvantages of each metal above.

The fact is that red brass and yellow brass exhibit differences in chemical composition, mechanical properties, corrosion resistance, and appearance, among other areas.

CNC machining services must address these differences to bring the best out of these alloys.

For more understanding of these differences, let’s go through them systematically:

Red Brass vs Yellow Brass #1: Appearance And Feel

The range of copper content in red brass means that the alloy’s color can be light pink. This attractive color tone makes the material popular for containers and in construction.

For yellow brass, the range in zinc percentage has a big effect on the appearance. If the zinc content is on the lower range, the material can look redder. It is brighter if the zinc content is more.

Appearance of red brass vs. yellow brass

Red Brass vs Yellow Brass #2: Chemical Composition

The chemical composition of red brass and yellow brass affects important aspects such as durability, strength, and application. The two may be brass metals, but as the table below shows, their chemical composition is different.

| Component | % in Red Brass | % in Yellow Brass |

| Copper (Cu) | 85 to 90 | 60 to 80 |

| Zinc (Zn) | 5-10 | 30 to 40 |

| Tin (Sn) | 2 (minimum) | 1 (maximum) |

| Lead (Pb) | 1 (maximum) | 1 (maximum) |

| Manganese (Mn) | 0.5 | 0.5 |

| Iron (Fe) | 0.1 | 0.1 |

| Arsenic (As) | 0.01 (maximum) | 0.01 (maximum) |

Red Brass vs Yellow Brass #3: Material Properties And Characteristics

While these copper alloys have more or less the same suitability for brazing and soldering, they differ in weight, corrosion resistance, and durability.

Red brass is more corrosion resistant than yellow brass is, mostly due to its higher copper content.

When it comes to durability, the harder yellow brass performs better than the softer red brass. This property is one of the reasons manufacturers prefer yellow brass for door knobs and plumbing fixtures.

Red brass is heavier and easier to machine than yellow brass. For the lighter yellow brass, adding a trace of lead can improve the machinability and expand the type of projects to use the material in.

Both alloys are easy to braze and solder.

Red Brass vs Yellow Brass #4: Formability

Formability refers to how easy a material can be molded into different shapes. Red brass is less formable than yellow brass.

Red Brass vs Yellow Brass #5: Strength

The two metals score differently in tensile strength. A higher tensile strength for red brass means the material can withstand more deformation when exposed to strain or stretching force.

The difference in yield strength for the two copper alloys is also markedly different. It is approximated at 435MPa for red brass and 97.0MPa for yellow brass.

Red Brass vs Yellow Brass #6: Price

Another notable difference between red brass and yellow brass is the price, which is largely related to the copper percentage. Copper, being an expensive element, contributes to a higher cost for red brass.

Yellow brass is generally more affordable and available than red brass for this reason. That explains why it is easier to CNC machine large volumes of yellow brass than red brass.

The comparison of red brass vs yellow brass is summarized in the table below:

|

Property |

Red brass |

Yellow brass |

|

Copper |

Approximately 85% |

60–70% |

|

Zinc |

Approximately 15% |

30–40% |

|

Color |

Reddish |

Bright gold |

|

Strength |

Moderate |

Higher tensile strength |

|

Machinability |

Good |

Better |

|

Formability |

High |

High |

|

Cost |

Higher |

Lower |

Try Prolean Now!

Similarities Of Red Brass And Yellow Brass

While there are several differences between yellow brass and red brass, some similarities are also evident. This is mostly because they share the same base metal.

A forged brass part

The most notable similarities are;

- The main alloying elements are similar – copper and zinc – although in different percentages

- The metals have good electrical and thermal conductivity

- They both well to forming, forging, and CNC machining processes

- Both yellow brass and red brass are widely used for the same applications, for instance, jewelry

Brass bangles

Red Brass vs Yellow Brass: Which One To Choose?

Choosing one between these types of brass depends on your project specifications. Whether the manufacturing steps follow CNC milling, turning, turn-milling, or Swiss turning, use the following tips for a faster decision:

Take Red Brass If:

- The CNC machined part will be used in chemical-ridden or moist environment

- You want the highest dezincification resistance

- The part must be stable in a critical environment

- You are looking for a material that offers high service life for marine and plumbing systems

- The part for harsh environment should have the best electrical properties and surface finish

Go For Yellow Brass If:

- You want the shortest cycle times in your CNC machining process

- You want cost-efficient parts with fairly good mechanical properties

- You are manufacturing car parts and consumer hardware

- The use area is not extremely corrosive

Yellow brass battery terminals

Further reading: All about CNC Machining

Conclusion

As seen in this discussion, red brass and yellow brass are popular copper alloys with applications across industries. It is understandable to be unsure which of these options to pick for your project because both are great metals.

After seeing the distinction that covers strength, appearance, corrosion resistance, and strength, among other factors, one can now make a more informed decision. At ProleanTech, we are excited to help our clients get the best from the numerous materials available for CNC machining services.

Whether with red brass or yellow brass, ask for our CNC machining solutions and we will consider all the properties to deliver the most reliable parts and components.

Our CNC machining specialists are waiting to guide you about these two popular copper alloys. Contact us now!

FAQs

Is red brass worth more than yellow brass?

Yes, red brass is usually worth more than yellow brass because it has more copper content.

What is red brass used for?

Red brass is commonly used for pump and plumbing components because it is machinable and corrosion resistant.

What is the best grade of brass?

While the best grade of brass depends on the use, C360 (free-machining brass) is popular with most users for its durability and easy machinability.

0 Comments