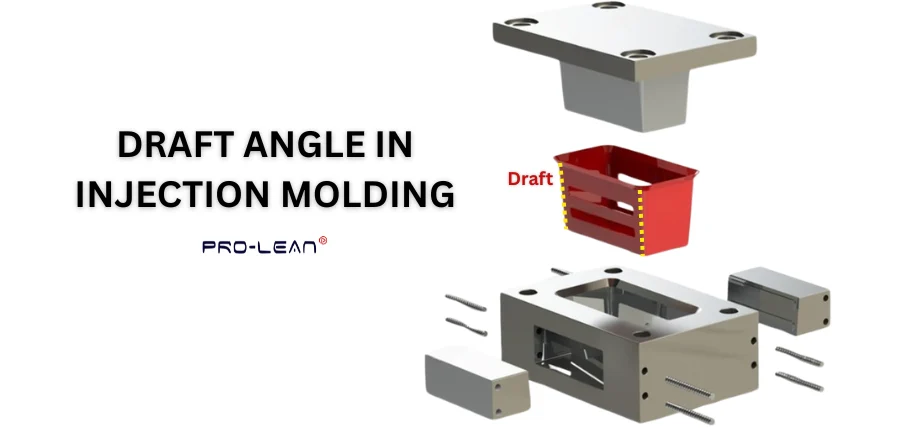

Draft angle in injection molding

Injection molding is a manufacturing process that can produce high-quality parts with precision and efficiency. In mold design and injection molding, the draft angle can significantly affect the success and errors in production.

In this guide, you’ll learn about how to examine draft angles, the importance of draft angles in injection molding, and solid guidelines for implementation to ensure effective mold design for part production on any scale.

What Is Draft Angle?

Draft angle

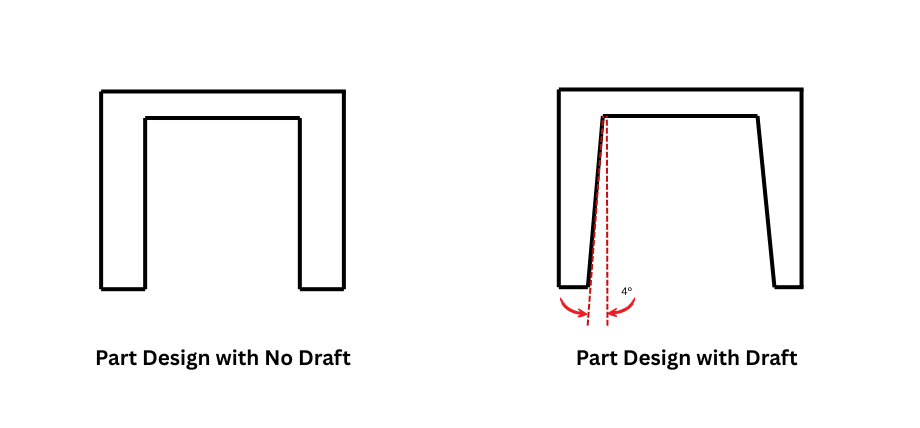

A draft angle turns vertical surfaces into a taper for mold cavity, so that you can eject parts from the mold. For injection molding, the draft angle is a very slight taper, enough that the plastic part can be removed from the mold without causing damage to the part or the mold itself.

The draft angle is applied to the mold walls and ensures the part can slide out smoothly during the ejection process.

Draft angle is essential in injection molding mainly because when the molten plastic cools within the mold, it undergoes shrinkage and may grip the core or cavity tightly, preventing ejection. Without draft angles, removing the part from the mold becomes difficult and almost always leads to damaged or defective parts.

The draft angle provides a slight taper to vertical surfaces, making it easier to remove the molded part. Draft angles have a typical range of 0.5 degrees to 3 degrees.

Importance of Draft Angle In Injection Molding

Draft angles are crucial to ensure design for manufacturability of injection molded parts. Draft angle along with wall thickness, ribs and bosses and other factors to consider in DFM play a pivotal role in injection molding process by allowing for a smooth removal from the mold.

Proper draft angles are important for DFM attributes that help prevent issues like sticking, scratching, or deformation during ejection of the molded part. Without draft angles, there’s a high possibility of the part sticking to the mold cavity or core.

Draft angle also plays another important role in mold opening process preventing damage to both the part and mold, especially when complex textures like embossed patterns or matte finishes are used.

Incorporating draft angles early on in the design stage is important for mold design. By designing in draft angles and incorporating them into the part design, engineers can ensure that the part is easier to remove. Another advantage of using draft angle is that it also minimizes risks of undercuts.

Try Prolean Now!

Guidelines for Draft Angles

Designing injection molds

When you design parts for injection molding, using tried and tested guidelines for draft angles is essential to achieving high-quality parts. The following are recommendations for applying the draft in mold design effectively.

- Minimum Draft Angle: A minimum draft angle of 0.5 degrees is the typical recommendation for most injection molded parts. In addition, the part’s geometry and the texture of the part dictate the minimum draft angles (around 3°).

- Standard Draft Recommendations: Use 1° degree of draft per inch of cavity depth for most cases but this depends on texture and material shrinkage as well. For molded parts with intricate designs or deeper cavities, a steeper draft is used for complete ejection.

- Materials: Different thermoplastic materials have different shrinkage and cooling rates. Which affects the draft angle requirements for that particular injection molding material. As a general rule, higher shrinkage materials require larger draft angles to compensate for the molten plastic as it cools.

- Texture / Surface Finish: The Texture of the part dictates the draft angle adjustments. Smooth surfaces can work with minimal draft angle, while textured surfaces, like a grainy finish, often require 3 degrees of draft, which helps prevent scuffling and abrasion during ejection.

- Parting Line: Draft angles are also affected by the design of the parting line. The parting line is the separating line of the two mold halves. Parting lines should be designed to align draft for mold opening and part removal from the mold.

- Core: The draft angle is applied to both the core and cavity sides of the mold, so that there is no damage to the mold. This is important for designs with undercuts and complex geometries.

| Draft Angle | Application | Description |

| 0.5 degrees | Smooth surfaces and small parts | Suitabe for parts that don’t have texture and for materials with low shrinkage |

| 1 degree | Standard parts | General purpose draft for injection molding. Follows the general principle: 1 degree of draft per inch of cavity depth. |

| 2 degree | Parts with moderate texture and deep cavities | Suitable for most thermoplastics |

| 3 degree | For rough textures | Necessary to prevent surface damage on the part and aid ejection. |

| 5 degrees or higher | Deep cavities | Used for complex designs to ensure smooth removal from the mold. |

Table for incorporating draft angles

Common Mistakes in Draft Angles

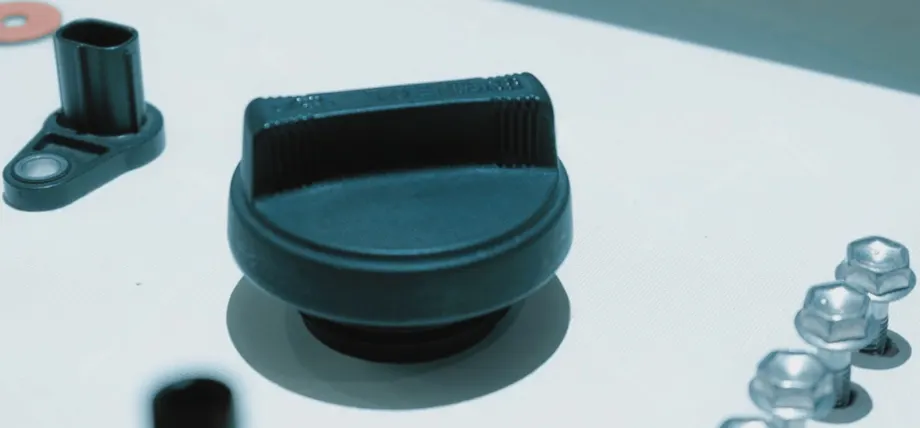

Plastic part with texture

In DFM, the most common error for injection molding is inappropriate draft angles during design work. Some of these mistakes include:

- Insufficient Draft Angles: The most common error is missing adequate draft angles. A zero draft or minimum draft angle can cause the part to stick to the mold which can in turn damage the mold or the part.

- Uneven Ejection: Inconsistent draft application across the part design leads to improper ejection because of the forces. Draft angles should be uniform in all vertical surfaces to ensure removal from the mold.

- Ignoring Material Properties: Different thermoplastics cool at different rates and have unique shrinkage. If you fail to consider material properties, the draft angle might be inadequate for releasing.

- Texture: More often, designers tend to ignore draft angle considerations for textures. Complex textures require draft angles with steeper drafts to avoid surface damage during ejection.

Zero Draft Angles Applications

Some mold designs can have zero draft angles. This is rare in injection molding, but can be used where the part design is such that it can allow part release or ejection without draft angles. A reason for this can be material properties, part geometry, or air channels.

In die casting, 3D printing, and CNC machining, zero draft angles can be used for some features which is rare but cases like flexible cores can use zero draft angle. But, in injection molding, zero draft angles are avoided because without draft angles, the part can grip the core or cavity, resulting in challenging ejection.

What Happens With Poor Draft Angles?

- Sticking and Mold Jam: Poor draft angles and insufficient draft angles can cause the part to adhere to the mold cavity. This makes it difficult to remove the part from the mold.

- Surface Defects: Without draft angles, the part may experience scuffing when released from the mold. For plastics, this is particularly damaging for aesthetics and smooth surface finish.

- Mold Damage: Excessive force is needed to eject the part when inadequate draft angles are used.

- Deformation: Plastics during ejection are still soft, and poor draft angles can cause uneven stresses during this ejection, resulting in deformation or warping.

What are the Applications of Draft Angles in Injection-Molded Parts?

Draft angles are used widely in injection molded parts for design for manufacturability (DFM) reasons.

Plastic Products

Most plastic products, everyday items like plastic containers, housings, and injection molded enclosures, require draft angles to ensure quick cycle times, aesthetics, and surface finish.

Automotive

Automobile bumper

In the automotive industry, injection molded parts like dashboards and interior components require draft angles for their high production cycles.

Electronics

The most common use of drafts is in electronic housings and devices like smartphone cases or computer chassis covers, and bottom panels. Here, precision draft angles are used with precision tooling to meet the quality standards.

Try Prolean Now!

How to Optimize Draft Angle for Plastic Parts?

There are many ways you can optimize the draft in injection molding. There are a few factors to consider from the DFM point of view.

Balancing Draft Angle with Mold Cavity Design

The design of mold, cavity, and core determines the right draft angle. The geometry of cavity and core, as well as the parting line location, needs to be considered when applying draft. For deeper cavities, the larger draft can accommodate the increased depth, while smaller cavities and shallower parts can work with a minimum draft angle.

Design Tips

For effective draft angle implementation, you need to use a design-oriented approach to material properties.

Align draft with parting line: design the draft placement to accommodate the parting line for mold opening. Misalignment here can lead to undercuts and uneven force for ejection, so it is wise to verify the parting line placement.

Simulate ejection: One way to avoid expensive tooling mistakes is to use mold flow simulation to analyse the ejection of parts and validate draft angle effectiveness.

Use factory mold makers: Mold makers process tens of mold designs every day, and their engineers can ensure draft angles are optimized for both part functionality and the injection molding process. This not only saves you time but also results in high-quality parts.

Injection Molding Service at ProleanTech

Prolean-Tech offers DFM support for injection molding and also produces low and high-volume injection molded parts. You can also take advantage of skilled engineers for mold making and tooling guide.

Reach out today for an absolutely free quote and support for your injection molding products.

Conclusion

Draft angles are widely used in injection molding by engineers and designers alike to ensure the design for manufacturability and quality of plastic parts and metal parts. By applying draft angles effectively, you can achieve the smooth ejection of parts.

By optimizing draft angles through careful design steps and tips outlined before you, it is possible to achieve an efficient molding process and deliver high-quality injection molded parts. Don’t forget to consider texture and material for the draft angle.

0 Comments