Drill Jig

Jigs and fixtures are manufacturing tools that hold the workpiece and provide a secure location for different workpieces during machining operations, ensuring precision and repeatability for CNC machining.

Jig and fixture are often confused, but there are key differences between these manufacturing tools that you need to understand to optimize the manufacturing process.

In this comprehensive guide you’ll learn about the purpose of a jig and how fixtures are different from jigs, and their applications across manufacturing industries. I’ll also share key tips to improve manufacturing quality.

What are Jigs and Fixtures?

CNC Fixture

Jigs and fixtures are tools used in manufacturing to hold a workpiece steady while the cutting tools can remove material during machining operations. Jigs and fixtures are important in the manufacturing industry because they ensure the workpiece or material stock is held in the correct orientation, place and is positioned correctly, which reduces errors and enhances the manufacturing process.

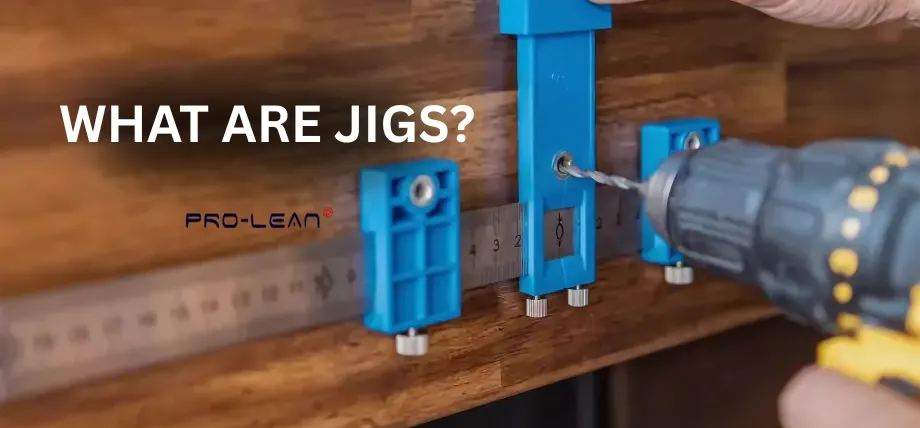

Definition of Jigs

Jigs are tools specifically designed to hold a workpiece. The cutting tool is guided by the jig during operations like drilling, tapping, or milling. The purpose of a jig is to make sure the tool used goes in the correct position and at the required angle.

Jigs are lightweight, typically portable, and can be reused if the same task is repeated. You can think of jigs working as a guiding tool for the cutter. For instance, a drill jig can have bushings that guide the drill bit for repeatability across multiple workpieces.

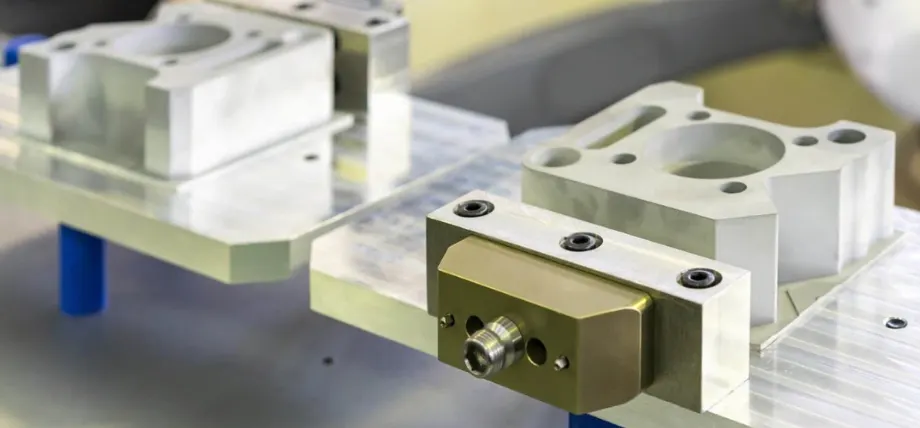

Definition of Fixtures

CNC fixtures with tool changers

Fixtures perform a similar function as jigs, but there’s a key difference. While jigs hold and guide the cutting tool, fixtures do not guide the cutting tool but provide a firm base and hold the workpiece in a fixed position during machining and assembly.

You’ll commonly find fixtures in CNC machining, milling and automatic welding. Fixtures can even be clamps that hold the workpiece to prevent any movement.

In CNC machining, fixtures play a key role in ensuring that complex features in components made during manufacturing are of the exact dimensions.

Jigs and fixtures are important in manufacturing because they improve efficiency in low to high-volume productions, reduce workpiece setup times, and improve manufacturing quality.

Jigs are a way to standardize the machining of workpieces by minimizing human errors and supporting repeatable manual or semi-automated processes.

What are the Differences Between Jigs and Fixtures?

As a manufacturer or engineer, you might come to a point where you need to design a jig or fixture. Understanding the difference between jigs and fixtures is key to selecting the right tool and saving time and costs during design.

Both tools are used to hold a product, but their roles and features are different. You can find subtle differences between these manufacturing tools by observing their use.

| Feature | Jig | Fixture |

| Primary use | Holds and guides the cutting tool | Fixes the workpieces in a fixed position |

| Guides the tool | Yes | No |

| Design | Simple and portable, repeatable use | Robust, solid and designed for heavy duty machining operations |

| Applications | Drilling, tapping, milling, etc | Milling, turning fixtures, welding and assembly |

| Materials | Lightweight metals and includes bushings | Heavy duty clamps and supports, often with adjustable grip on parts. |

Key Characteristics of Jigs

Jigs can be defined by their characteristics, and features of jigs include workholding and guiding the tool. Other key features of jigs are portability, designing for specific operations like drilling or tapping.

Welding jigs position the workpiece accurately for quick and consistent welds during assembly, ensuring consistent welds. Sometimes, jigs are 3D printed for rapid prototyping before turning them into permanent tools.

These features make jigs critical manufacturing tools that enable accurate, precise and repeatable results.

Key Characteristics of Fixtures

Fixtures are critical manufacturing tools designed to simply clamp the workpiece in place for machining operations. Fixtures are often made from stainless steel or cast iron to withstand cutting forces and vibrations during machining operations.

There are many types of fixtures, like turning fixtures that secure cylindrical workpieces on a lathe machine or modular fixtures for specific machines and processes.

When to Use a Jig vs a Fixture

CNC Turning Fixtures

Your manufacturing needs will help you decide if you need a jig or a fixture. Jigs are ideal for tasks that need tool guidance and precision, like tapping or threading.

Fixtures can be designed to elevate or reposition the workpiece when standard clamping does not provide optimal access for the spindle or tool. So a raised fixture can be designed to assist machining while keeping the workpiece stationary.

Try Prolean Now!

How to Design a Fixture?

Fixture design is important for CNC operators and designers in manufacturing. Poor fixture designs can misalign the workpiece, reducing precision and increasing errors.

Essential Features of a Good Fixture Design

A well-designed fixture needs to be stable, strong and ensure stability. Key design features of fixtures include

- robust clamps

- Locating pins

- Dimensions within the machine bed frame

- Compatibility with the size of the cutting tool

- Chamfered edges help avoid interference during loading/unloading or tool movement..

- Quick loading and unloading features

- Materials that do not deform

Fixtures need to work together with the CNC machines to hold the workpiece steady and improve manufacturing quality.

When designing fixtures for CNC machines, particularly, the most important consideration is the workpiece shape and geometry. Second, you should consider the machining forces and the CNC machine’s capabilities.

What are the Advantages of Using Jigs?

Jigs are useful in high-volume manufacturing where efficiency and part production speed is important.

Improving Precision with Jigs

Jigs enhance precision by providing a guiding path to the cutting tool for the exact cut location. Manufacturing precision is critical in industries like aerospace and electronics, where small deviations can render the entire part useless.

Enhancing Repeatability in Manufacturing

Jigs are tools that enable repeatability and ensure that the workpiece machined into parts is identical.

Reducing Setup Time with Jigs

Jigs simplify the positioning of design features and secure the workpieces, reducing setup times. On assembly lines and sequential machining, time savings translate into cost savings, allowing operators to quickly align workpieces and improving the manufacturing process.

How are Jigs and Fixtures Used in Different Applications?

Jigs and fixtures

- Drilling: Jigs are most commonly used in drilling to provide a clear path for the drilling bit. For example, a drill jig can ensure that the drill penetrates the workpiece at the right angle. Jigs allow angular cuts in standard linear-axis milling machines.

- Welding and Assembly: Fixtures are important for welding and assembly during part fabrication. Fixtures hold components in precise alignment. In assembly lines in the automobile industry, hardworking fixtures that secure cars guide them through welding lines and seam placement.

- Additive manufacturing: 3D printed jigs and fixtures are cost-effective for low-volume production and prototyping, offering rapid turnaround times and design flexibility.

- CMM and laser scanning: Manufacturing quality is often assessed using CMM and lasers, but fixtures play an important role in holding the workpiece during these scans in precision manufacturing.

Try Prolean Now!

What are Modular Fixtures and Their Benefits?

Modular fixtures are a type of fixture design that are adaptable and save costs in dynamic manufacturing environments.

Understanding the Concept of Modular Fixtures

A modular fixture has components that can be removed and replaced. They are useful in manufacturing industries that produce parts for more than one project. Modular fixtures reduce setup times and lower costs by avoiding the need for additional fixtures.

They are particularly useful for electronic assembly because they can be adjusted to hold different sizes of enclosures and streamline production.

Example of Modular Fixtures in Practice

In CNC machining, modular fixtures are used to hold a variety of workpieces, from small components to large parts. Modular assembly fixtures hold different parts during assembly and can adapt to different model variations. For example, an assembly line for smartphones that can adjust to different screen sizes.

Conclusion

Jigs and fixtures are both key to accurate manufacturing, and the choice between them depends on the scale of production and task repeatability.

By learning subtle differences between jigs and fixtures, manufacturers can reduce costs and make their manufacturing more efficient. Jigs and fixtures have evolved from standardised tools to custom-made 3D printed fixtures and modular fixtures, shaping many industries like electronics and automotive.

Custom CNC Machining Jigs and Fixtures at Prolea-Tech

Are you looking to manufacture custom jigs and fixtures? Or does your part manufacturing require custom jigs? At Prolean-Tech, we have the capability to produce your custom parts using custom jigs and fixtures.

You can receive an absolutely free quote today!

FAQ

What is a jig used for?

A jig is used to guide and hold parts during manufacturing. Jigs ensure precision and repeatability in tasks like tapping and drilling.

What is an example of a jig?

An example of a jig is a drill jig, which has pre-cut holes and aligns with the part edge to drive the drill bit at the exact location.

But what are jigs and fixtures, what are jigs and fixtures used for, and why are jigs and fixtures so important?

Jigs guide tools and hold the workpiece, but fixtures only hold the workpiece. Both reduce errors and increase accuracy but jigs also improve manufacturing efficiency.

Are jigs and fixtures the same thing?

Jigs guide tools and can hold the workpiece, but fixtures only perform the function of holding the workpiece.

How are jigs and fixtures manufactured?

Jigs and fixtures are made by the same process as a part design. You can think of jigs as parts and use CAD and CAM to manufacture jigs.

How does a fixture differ from a jig?

A fixture only holds the workpiece steady and decreases vibrations and misalignments, but a jig guides the cutting tool.

How to manufacture jigs and fixtures?

Start by making a CAD model and selecting durable materials like stainless steel and then machining using CNC technology.

Jigs or fixtures?

Deciding between jigs or fixtures depends on the task and precision needs.

So why do manufacturers use jigs?

Jigs ensure proper tool placement, enhance production speed and maintain consistency in parts.

What Are Jigs?

Jigs in manufacturing guide tools and secure workpieces for repeatable manufacturing and consistency across products.

What operators use jigs and fixtures?

CNC machinists and traditional machinists use jigs and fixtures to ensure accuracy and efficiency in production.

What types of materials are common in jigs and fixtures?

Jigs and fixtures are generally made from steel or aluminum. For lightweight tasks and plastic machining, some jigs are also made from plastics like nylon.

0 Comments