Aerospace sheet metal fabrication

Aerospace design and manufacturing go hand in hand with innovation and advancement. If there is one area that allows these elements of the industry to thrive, it is aircraftsheet metal fabrication.

The process of transforming flat metal sheets into usable items for the industry remains a core of the manufacturing process. Processes such as folding and punching are constantly getting improved for the continual betterment of the industry.

It is through sheet metal fabrication that ProleanTech is able to produce sheet metal parts for the fuselage, wings, interior, landing gear, and much more. Because of the huge importance of this production method, we prepared this guide for more insights.

Read on to learn about the basics, the aerospace materials used, and the common parts built from sheet metal fabrication in the aerospace industry.

What Is Sheet Metal Fabrication?

Sheet metal fabrication is the manipulation of sheet metal to create different usable shapes and sizes. Techniques such as punching, bending, and cutting are used. Often, sheet metal fabrication results in a product or component larger than the individual pieces.

Sheet metal fabrication processes

These individual metal pieces are joined together through techniques such as riveting and welding. Therefore, sheet metal fabrication in the aerospace industry is wider than many people might think.

Indeed, there is dedicated software and steps for this process. Some of the related tools and approaches we use at ProleanTech are;

- CAD design software

- Laser cutting

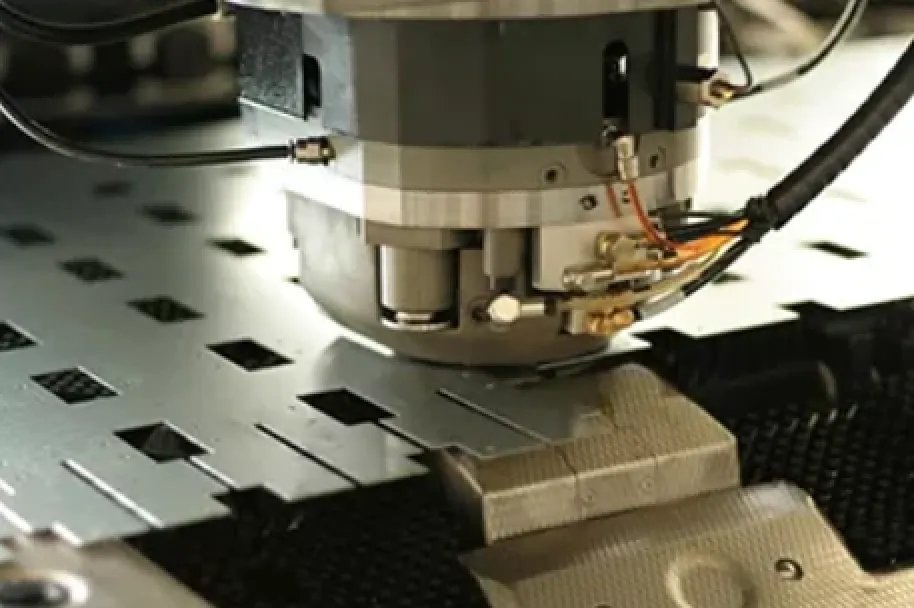

- CNC machining tools

- Powder coating facilities

- Precision punching

- And more

Requirements For Quality Aircraft Sheet Metal Fabrication

There are high stakes in this critical industry. That’s why the sheet metal products here must meet strict standards for safety and reliability. The quality of the products must be unquestionable.

Only a world-class fabricator like ProleanTech can meet the requirements for tolerances, material quality, and safety compliance. The fabricated parts are used in harsh conditions with no room for error or complacency.

We commonly fabricate sheet metal from different aerospace materials, including common ones such as aluminum alloys and stainless steel. You can always ask for a quote for aerospace fabrication, and we will respond promptly.

We always adhere to industry standards. For instance, we comply with the AS9100 certification for materials. This certification is an extension of the ISO 9001 standard but is dedicated to the aerospace industry.

The Importance Of Precision Sheet Metal Fabrication In The Aerospace Industry

The aerospace industry is incomplete without precision sheet metal fabrication from reputable firms. ProleanTech fabricates parts for the industry in both prototype and on-demand production capacities.

The materials and processes are limitless, and the parts turnaround can be as fast as one day. Upload your design to get a prompt quote, and the production will start immediately.

We recognize the importance of precision sheet metal fabrication for the industry and strive to maintain the highest manufacturing standards. Consider these benefits of the parts:

Safety Of The Product

The components used in aerospace manufacturing must meet the highest safety standards. Precision sheet metal fabrication ensures that parts are made to the tightest tolerances to minimize flaws. When parts are made accurately and precisely as designed, there is a level of assurance to the user.

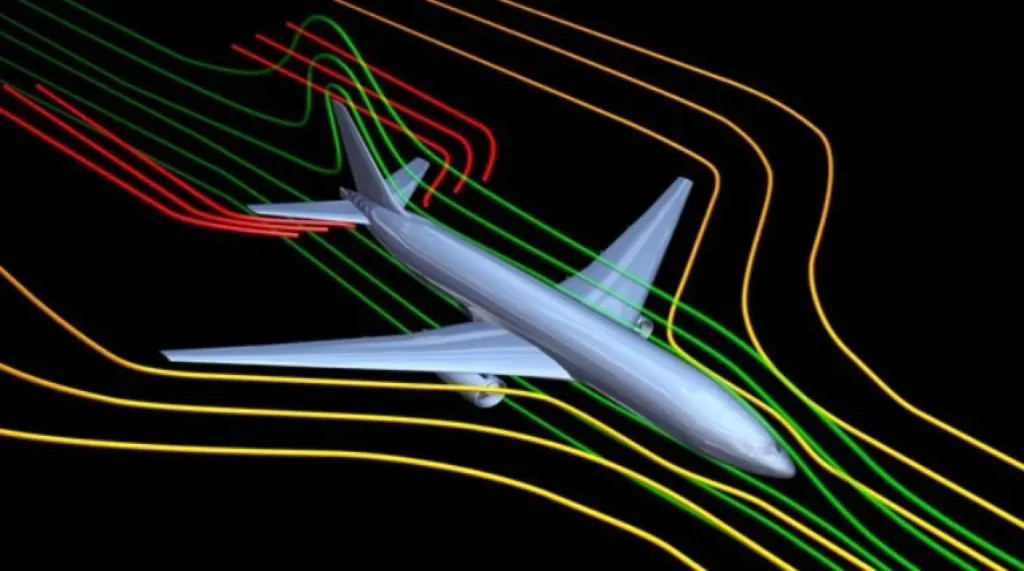

Superior Aerodynamic Performance

The aerodynamic performance of an aircraft as it glides through the air depends on many factors, including the quality of the sheet metal parts. It is important to use sheet metal parts that have been manufactured to the best profiles and surface finishes.

Precision sheet metal fabrication for aerospace ensures smooth airflow and flawless overall performance of the aircraft.

Aerodynamics of an airplane

The Right Weight For Aerospace Applications

Like other critical industries, the aerospace industry requires products with a high strength-to-weight ratio. Through expert sheet metal fabrication, the industry gets sheet metal parts of the highest quality and ideal weight. The optimized weight ensures fuel efficiency and safety.

Structural Integrity Of The Parts

Along the same argument, parts in this industry must be sturdy and dependable. Quality sheet metal fabrication produces parts that can meet the functionality and durability requirements.

We could go on and on with the benefits of precision sheet metal fabrication for this critical industry. For more insights and to know our capabilities, get in contact with our experts today.

The Materials To Consider In Aerospace Sheet Metal Fabrication

Getting it right with sheet metal fabricated materials for aerospace is critical. Already, the industry has conditions that a material must meet for safety, reliability, durability, and efficiency. Corrosion resistance, strength, and weight are some of the non-negotiable properties.

We are careful about the types of aerospace materials we use for sheet metal fabrication. We have a strong team of material scientists and engineers who can advise why any particular metal is selected.

Popular metals for sheet metal fabrication for aerospace are highlighted next:

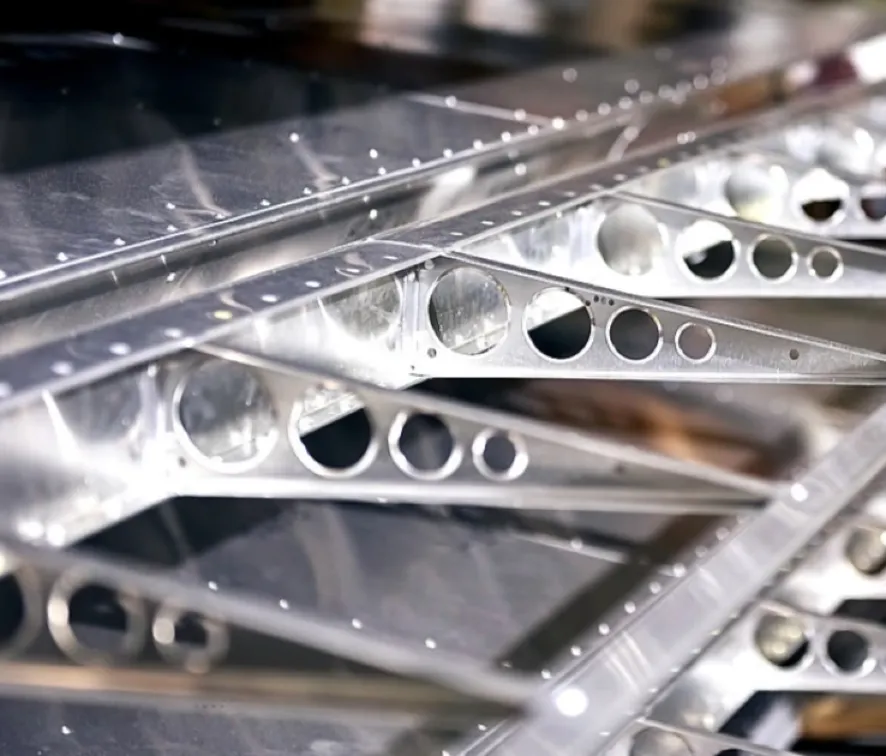

Aluminum: Available, Lightweight, and Strong

Aluminum is not only readily available, but also lightweight and strong, hence suitable for aerospace applications. Its sheets are commonly used for wings and fuselage parts.

Aerospace aluminum grade sheets

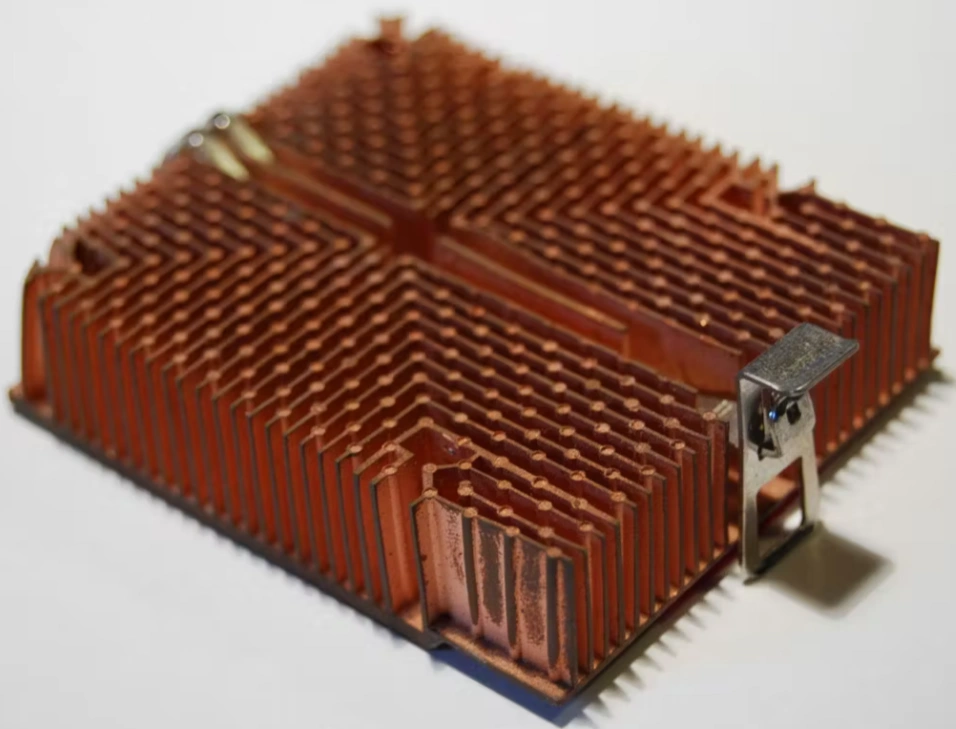

Copper Alloys: Electrical And Thermal Conductivity

Copper alloys are also significantly important in aerospace parts manufacture. Their most notable properties are superior thermal and electrical conductivity.

Copper heat sink for aerospace

Fabricated sheets of copper grades make excellent cooling and electrical systems for aircraft. That the alloys are corrosion and wear resistant makes the material even more appealing for the tough aerospace conditions.

Stainless Steel: Superior Mechanical Properties

Comprising iron-carbon alloys and up to 30% chromium, stainless steel is a perfect material for custom aerospace sheet metal fabrication. The biggest selling point for this material are the excellent mechanical properties within most working temperatures.

Aerospace applications are synonymous with tough conditions, but stainless steel is good enough. Some sheet metal fabricated areas made of stainless steel include jet engines and airframes.

Stainless steel frames for aircraft

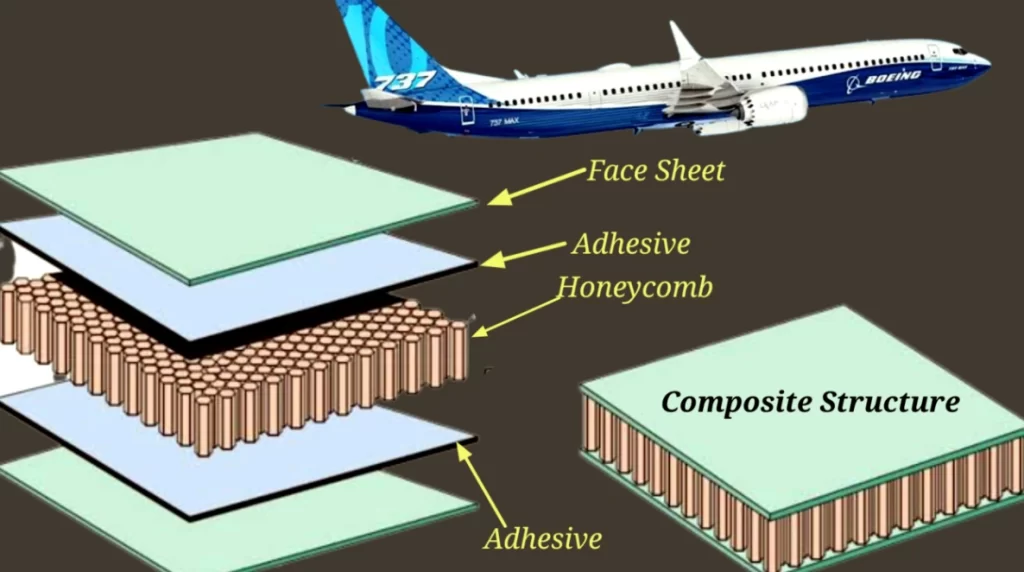

Composites: Lightweight And High-Performance

Aluminum may be light, but not more than composites. These materials are also high-performance, and that’s why they have increasingly appealed to aerospace manufacturers.

A composite sheet

Aramids and fiberglass are among the most popular composites for sheet metal fabrication in the industry.

Titanium: High Strength-to-Weight Ratio

Titanium is equally preferred for sheet metal parts for the aviation industry. When combined with aluminum and vanadium, it makes an excellent material for many sheet metal components of this industry.

A notable property of the metal is a high strength-to-weight ratio, which is ideal for aerospace requirements. Its yield strength, hardness, and durability are also suitable for this demanding industry.

Parts made from titanium fabricates sheet for the industry are aiframes, jet engines, and others.

Brass: Hard, Corrosion-resistant, And Temperature-Tolerant

Brass is an alloy containing copper and zinc, so it has desirable properties such as corrosion resistance, temperature tolerance, and excellent hardness. It is also suitable for harsh conditions like those of the aerospace industry.

Brass sheet metal parts for this area include electrical casings and wheel components.

Your Methods For Aerospace Sheet Metal Fabrication

There are many methods of sheet metal fabrication in the aerospace industry. Some are more advanced than the others but the goal is the same – to create precise, functional, and durable parts.

In the hands of ProleanTech, each of the following methods adds to the quality and reliability of sheet metal fabrication for the industry.

Whether it is sheet metal bending, welding service, or sheet metal cutting, we have excellent machines and highly experienced personnel to deliver the best results.

Now, to the most popular sheet metal fabrication techniques and their relevance to the aerospace industry.

It all starts with the computer aided design (CAD) step, which is followed by the following processes.

-

Mechanical Cutting

Sheet metal can be cut through melting or burning, but the mechanical approach still applies. That’s where die cutting and shearing come in. Shearing entails putting the sheet metal or a fixed die and punch-pressing it.

As long as the required sheet metal part is not complex, mechanical cutting is very cost-effective.

-

Thermal Cutting

Thermal cutting is the use of melting or burning to cut sheet metal. There are two popular options, namely laser cutting and plasma cutting.

Laser cutting is more common in sheet metal fabrication because of its precision and speed. However, it may not be satisfactorily effective in thicker materials.

Plasma cutting does better with thicker metal sheets. However, this only holds true for sheets thicker than 10mm.

-

Bending

Sheet metal bending

Many sheet metal components in aerospace have to undergo bending, which entails putting a curvature to the material through pressure application. There are many machines for this process, including an automatic bending machine and a manual press brake.

-

Punching

Sheet metal punching

Many components of aircraft require holes or perforations including fuselage panels, landing gear doors, equipment enclosures, and engine ducts. To achieve this, the manufacturer uses CNC punching technique to create the required holes or indentations.

-

Assembly

Assembly is a critical step in sheet metal fabrication. It involves joining the different sheet metal parts to form the final product. The techniques involved can vary based on the part’s complexity.

Simple parts can be joined using basic welding, while more complex ones require special assembly methods. Some may require nuts or rivets.

-

Powder coating

Powder coating entails the electrostatic application of powder to a sheet metal part. It is a surface finishing process that is common in aerospace manufacturing. At ProleanTech, we use advanced powder coating methods that promise durable and reliable performance of the sheet metal components.

Examples of sheet metal fabricated parts you may need in aerospace

You may still be wondering which aerospace parts are the result of sheet metal fabrication. There are many such parts, and we are always excited to participate in their manufacture.

We use our extensive familiarity with 100+ material types and our capability to use different aerospace fabrication processes. Some common parts in this respect are;

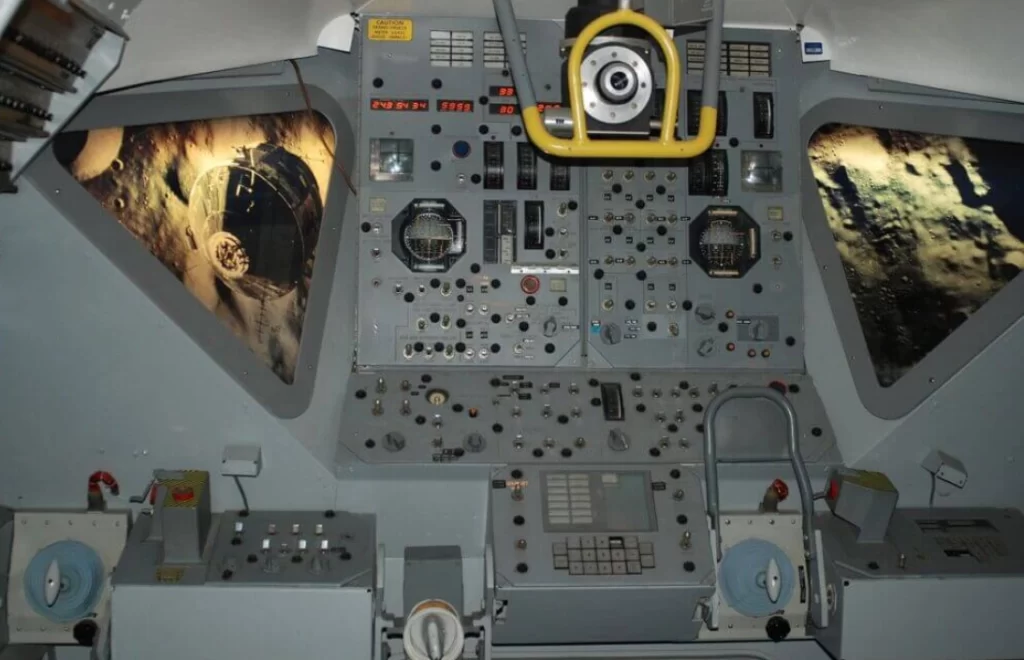

- Cockpit components

Cockpit components

- Fuselage panels

- Electrical panels and enclosures

- Other structural parts

Conclusion

Over the years, ProleanTech has completed countless sheet metal fabrication projects for the sensitive industry. The unrivaled success has led to extensive popularity locally and overseas. Our clients trust our capability, and we never disappoint them.

The secret is in investing in the right personnel and the latest equipment and processes. So, your search for cost-effective, durable, strong, and reliable sheet metal components for the aerospace industry should stop here.

We provide the standard sheet metal fabrication services, and can also provide custom services. Our dynamism will ensure that the parts will suit your project regardless of the environment.

To learn more about our capability, contact a ProleanTech representative today.

0 Comments