CNC metal milling vs wood milling

Computer numerical control (CNC) metal milling is a renowned machining method across industries for accuracy, versatility, and efficiency. The diversity of metals and non-metals for CNC milling is as wide as the possible parts. There is a reason why CNC Metal Milling vs Wood Milling is such a hot topic.

Wood is a popular non-metal for the production of parts like molds and prototypes. Among metals, there is an ever-wider range of products.

In your line of work or business, recognizing the difference between the two processes is crucial. The specifics of each process and the properties of the parts differ, so this knowledge can help one source the right parts.

However, the CNC process in the two cases is similar – a rotating tool removes material from metal or wood. The CNC milling expertise and advanced machinery at ProleanTech – Your Cutom Parts Manufacturing Partner– are exactly what you need to get CNC-machined wood or metal parts exactly how you want them.

So, how do CNC milling vs wood milling compare? Let’s do a thorough analysis of these two CNC machining processes.

CNC Metal Milling For Precision Metal Projects

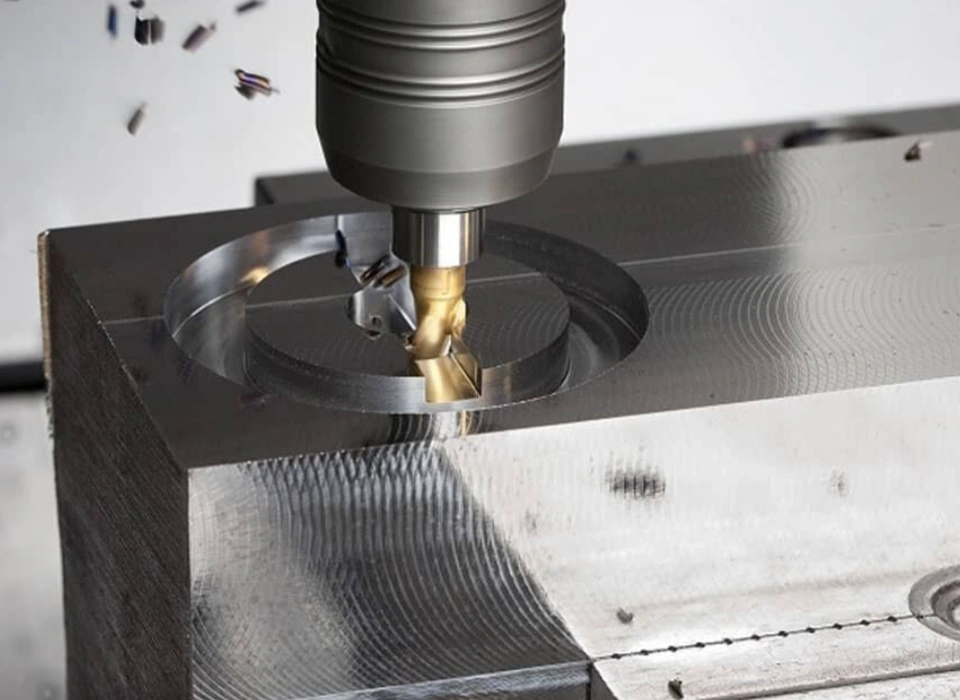

CNC milling machine metal milling removes material from a metal workpiece using a computer-controlled approach. It can create simple and complex metal parts based on the client’s requirements. This alone can explain the difference between milling and welding.

Project cost and duration differences could exist, but the approach is largely the same. Check how to choose cost-effective CNC milling for a better management of the cost aspect.

The CNC machine for metal milling is guided by a computer program (G-code). In other words, it follows a preset path as it cuts the metal. For successful CNC metal milling, the designer and operator must ensure the accuracy and precision of the parts.

CNC milling program

This is important because CNC-milled metal parts are used in many critical industries. Some of these industries are extremely sensitive, for instance, the medical and aerospace industries. They give no room for errors because that would mean risking human life.

CNC metal milling for aerospace

This guide on how to improve efficiency in CNC milling details the approaches ProleanTech follows to ensure the most dependable milled parts.

Our CNC metal milling is a professional process involving design, programming, and file conversions, alongside the CNC milling process. All these steps require expertise and advanced machinery for quality results. Considerations for the specific metal being used are also critical.

If you would like to get more in-depth information about the milling process, visit this Complete Guide to CNC Milling.

Try Prolean Now!

Popular Metals For Metal Milling

Metals are popular milling materials for various reasons. Given the different tastes and requirements, this process has many applicable metals, including stainless steel, aluminum, copper and bronze.

You can always choose the suitable metal for your project and let us CNC-machine it perfectly.

If you have challenges settling on any of the following metals for milling, contact us now, and we will be pleased to help. We know every metal and its properties like the back of our hands because we have handled over 100 different materials.

Stainless Steel With Strength And Corrosion Resistance

Stainless steel is corrosion-resistant, durable, strong, and versatile, hence suitable for many projects. Four grades of the material are common in CNC milling applications: austenitic stainless steel, martensitic stainless steel, ferritic stainless steel, and duplex stainless steel.

CNC milling Stainless steel

Aluminum’s High Strength-to-Weight Ratio

Aluminum is also common in CNC metal milling projects, particularly due to its machinability. Manufacturers produce a range of precision parts using this reliable metal. For its high strength-to-weight ratio, aluminum is often CNC-milled and used in the aerospace and automotive industries.

Other attractive characteristics of the metal are electrical conductivity, corrosion resistance, and recyclability.

CNC milling aluminum

Brass With Excellent Machinability

Brass is an alloy of copper and zinc. It has good machinability due to its copper and lead content. Its mechanical properties also promote suitability for CNC milling processes.

Some of these properties are high corrosion resistance, good wear resistance, and aesthetic appeal. Common grades of brass used in CNC milling include C360, C330, C385, and C464.

CNC milling brass

Titanium For Strength and Temperature Resistance

Titanium is also one of the best metals for CNC milling. It is temperature-resistant, lightweight, and strong. You should also consider this material for its non-toxicity and incredible durability.

CNC milling titanium

Provided the manufacturer takes care of embrittlement, cutting forces, and heat generation during machining, this metal is one of the best to machine. Its precision parts are common in aerospace, naval, and medical industries, among others.

Popular grades of titanium to consider for CNC metal milling include T6Al4V-ELI, Ti0.3Mo0.8Ni, Grade 4 titanium, and Ti6Al4V.

Try Prolean Now!

What is CNC Wood Milling And Is It Relevant?

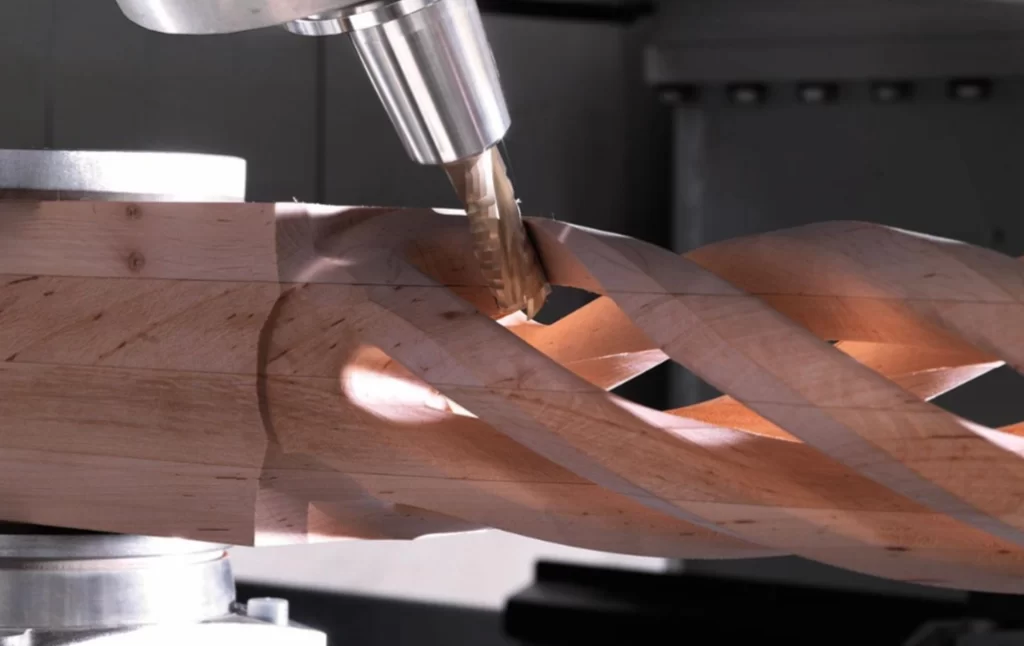

CNC wood milling is a process of using a CNC wood milling machine to remove material from wood to acquire a specific shape and size. It is common in furniture, architecture, and woodworking, among other industries.

CNC wood milling for architectural application

Like metal, wood is compatible with the CNC milling technology because the material is available in different types. Pine is a popular softwood that is easy to machine. Hardwoods also apply in CNC wood milling. Users have a lot of interest in durable and strong parts made from oak and other hardwoods.

CNC wood milling entails a computer-controlled machine carving or shaping wood to produce the desired component. Special instructions are fed into the CNC milling machine, enabling the tool to follow pre-determined parts to perform the task.

Types of Woods Applicable in CNC Wood Milling

Softwoods and hardwoods are common in CNC wood milling. They have varying properties and capabilities, so their specific applications can differ. Consider factors such as durability, aesthetic appeal, and cost when choosing between these categories of wood for CNC milling.

Softwoods for CNC Wood Milling

Softwoods are ideal for milling wood machine projects where ease of cutting and manufacturing speed are the priorities. The best examples of softwoods for CNC milling are cedar and pine.

CNC milled cedar

These woods make cost-effective shelves, frames, and other minimal-cost items. Other options are redwood, fir, and spruce.

Hardwoods for CNC Wood Milling

CNC milling for hardwood

For more scratch-resistant and durable products, consider using hardwoods in CNC milling. Options such as maple and oak are strong enough to be used for durable items such as tables and chairs. These milling materials also support the attainment of tight tolerances and very smooth finishes.

Other hardwoods to consider for CNC milling are birch, mahogany, beech, and cherry.

What Are The Options for CNC Wood Milling Machines?

There are different wood CNC milling machines, each with its capabilities and relevance. A good manufacturer can use the right combination of milling machines and software to produce excellent wood parts.

CNC Wood Milling Using A Router

The CNC router is the most popular tool for wood milling. It is reliable for accurate cutting of different types of wood, including ebony, beech, and oak. This machine is the answer to machining processes that are beyond the standard tools.

CNC router

The CNC router is perfect for creating roundings and bevelled recesses. It is fast and accurate in both 2-D and 3-D milling projects. It is better than a skilled machinist because its paths are preset.

Note that in this category, there is a type of CNC machine that cuts wood and metal.

CNC Bed Mills For Wood

A CNC bed mill is perfect for large pieces of wood. It comprises a sizable bed to allow for easy vertical and horizontal movements of the milling tools. Apart from being accurate, these machines are very versatile. With many tool options, it can produce virtually any type of milled surface on wood.

CNC 3, 4, and 5-axis Wood Milling Machines

These CNC machines share the same basic technology, but their capabilities in wood milling are different. Areas where capabilities differ are in part complexity, with higher axis versions having more capability.

CNC 5-axis wood milling

The machines also have different positioning options. For instance, the CNC 5-axis wood milling machine has more positioning options than the 4-axis version. Differences are also evident in production time, programming complexity, and customization degree.

All in all, these machines are perfect for CNC machining high-quality wood parts.

The Similarities Of CNC Metal Milling And Wood Milling

There are several similarities for CNC Metal Milling vs Wood Milling, including the basic milling principle and the machine components used for custom CNC milling for high-quality parts. We would like to highlight these areas because they help you better explain part capabilities to users.

- The machining components are similar

- The milling principle is the same for metal and wood milling process

Overall, we see that both techniques enlist the 6 major advantages of CNC milling, which you can enjoy when you partner with ProleanTech.

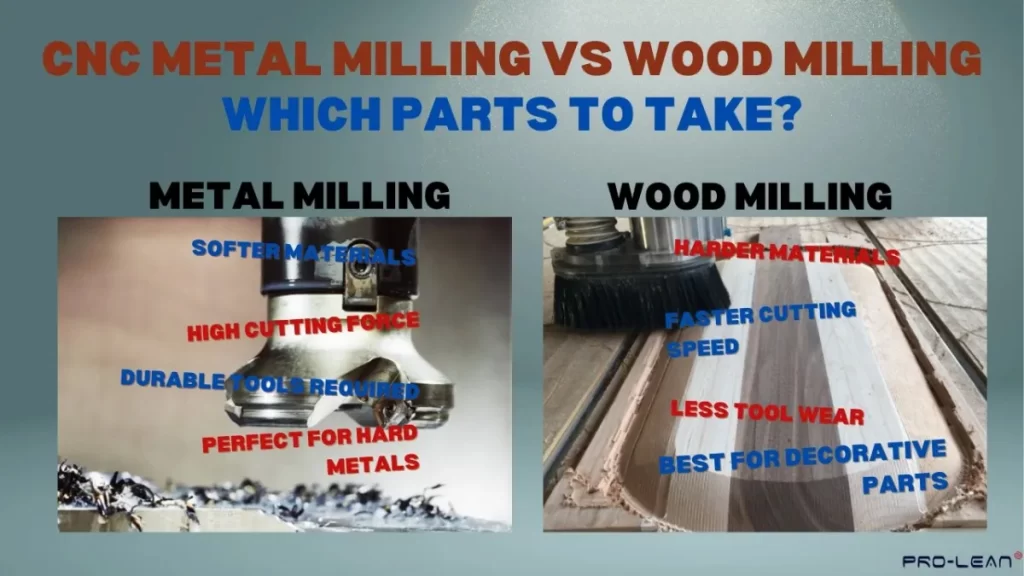

Main Differences Of CNC Metal Milling vs. Wood Milling

We must mention that there are differences between CNC metal milling and wood milling processes. Since the applications and properties of the two material categories differ, the CNC milling processes, tooling, and machining tolerances are some areas expected to be different.

Here is a rundown of the main differences between CNC metal milling and wood milling:

- The milling tools are different

- Metal and wood properties are different

- The specific milling methods for the milling materials are different

- The products of the milling materials have different applications

Ask ProleanTech for CNC milling services for either metal or wood because we have the right team and equipment for this type of machining. Our intent is to always deliver quality parts, regardless of the material.

We know how to improve efficiency in CNC milling and will apply such approaches in the project to exceed your expectations.

In Conclusion

CNC milling for metal and wood is essential for different industries. Wood and metal are distinctive materials with widely varying properties, so it is expected their CNC machining approaches would differ.

We have highlighted the similarities and differences of CNC Metal Milling vs Wood Milling to guide on the manufacturing requirements, the parts, and much more. This knowledge is crucial in understanding the capabilities of the different CNC machined parts.

Are you struggling to find quality CNC-milled wood or metal parts that meet your project specifications? ProleanTech has the expertise and technology to deliver the exact components you are looking for. Our CNC milling machine metal and wood expertise is unmatched.

Get in touch today to get an instant quote.

FAQs

What does a milling machine do?

A milling machine uses a rotating tool to remove material from a workpiece, for instance, wood or metal.

How to mill small metal parts?

Milling small metal parts requires the use of a sturdy and stable CNC machine and the right cutting tool. These should be combined with a coolant and the right machining parameters.

Can you CNC mill wood?

Yes, you can CNC mill wood to produce various parts for artwork, furniture, and so on.

How much does it cost to get something CNC milled?

The cost of CNC milling something is not standard because it depends on various factors, including milling duration, part material, and part complexity.

What is the difference between CNC milled and forged?

The difference between CNC-milled and forged parts is mainly in strength and precision. CNC milling is ideal for producing precise parts because of the computer control aspect. The heating and compression in forging produces less accurate but strong parts.

What is the best wood for CNC milling?

The best wood for CNC milling depends on the project goals. Softwoods such as cedar and pine are ideal for fast machining, while hardwoods like oak and maple suit strong parts.

How thick of wood can a CNC machine cut?

The thickness of wood that a CNC machine can cut depends on the wood hardness, tool size, and machine spindle capability. An industrial machine will typically cut thicker wood than a standard router can.

What are the disadvantages of CNC milling?

The disadvantages of CNC milling are the requirement for a skilled programmer, the typically high cost of the machine, and the long setup time for intricate parts.

What are the prices for CNC milling?

The prices for CNC milling can vary significantly depending on the part’s complexity, labor costs, and material.

0 Comments