Screw machining is a high-precision manufacturing process that uses automatic turning to create custom screws from a bar stock. The process involves a Swiss screw machine with multiple tools that precisely shape and finish cylindrical workpieces.

Screw machining is crucial to many industries, specifically for watches, tools like drills, and medical implants.

In this article, you’ll learn about screw machining processes, why Swiss screw machines efficiently produce screws, and how to choose between turning lathes and Swiss-type lathes.

What Is Screw Machining?

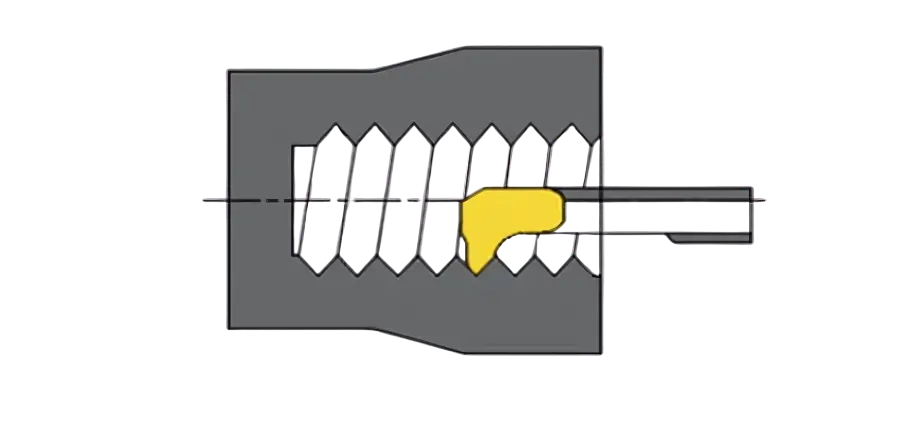

TITLE: Threading process with a single point tool

Screw machining is part of automatic lathe operations that uses a cylindrical stock rotating at high speeds with a single-point cutting tool performing operations like turning, threading, reaming, and boring. At the end of these operations, the cylindrical stock turns into a screw.

Screw machining on spindle lathes generally involves turning to create a profile and using a stationary drill bit to create a precise hole. Finally, while the workpiece is still rotating, a threading tool can cut external or internal threads to make the screw.

While screw machining can be done on traditional lathes, most CNC machining services use screw machines, multi-spindle lathes, or Swiss screw machines that offer minimal operating time.

Swiss Screw Machining

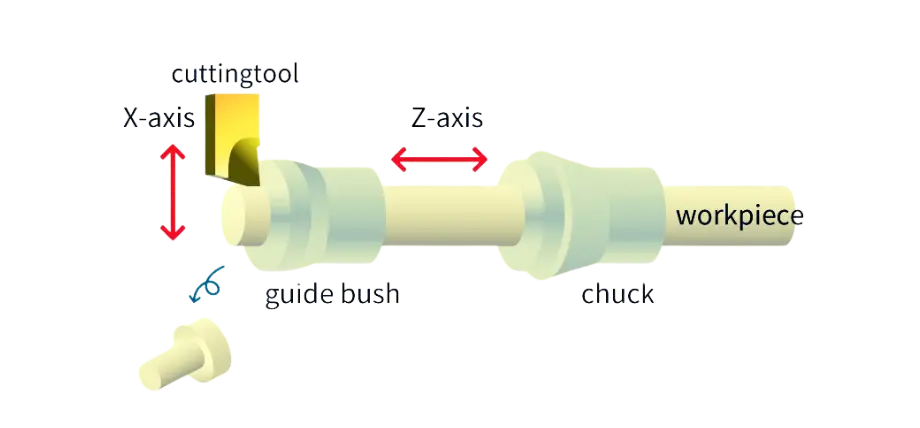

TITLE: Mechanism of Swiss Screw Machine

Swiss screw machining removes material from a cylindrical workpiece supported by a guide bushing. The headstock holding the workpiece can also move in the Z-axis, which allows more precision.

Swiss screw machines feed the bar stock through the guide bushing, which reduces deflection and enables multi-axis tool machining simultaneously.

Swiss screw machines have short cycle times and produce multiple screws at the same time. Swiss CNC machines can perform.

- Turning

- Drilling

- Threading

- Milling

- Boring

- End cutting

- Multi-axis (5-axis) cutting

CNC Machining VS Swiss Screw Machining

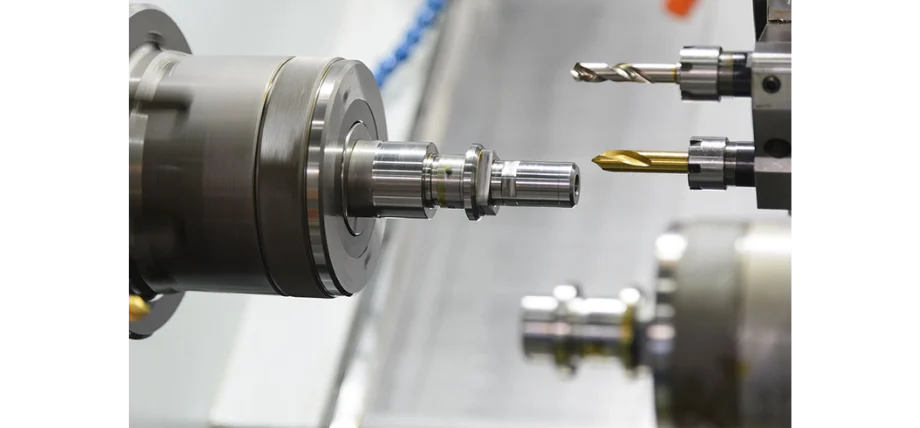

TITLE: Custom CNC machined ball screw

CNC machining uses Computer Numerical Control (CNC) to automatically control lathes and milling machines that manufacture screws and threads. The process typically starts with a CAD design turned into a G-code for the CNC machine as instructions to start cutting.

CNC screw machining typically involves cutting tool motion in 3-axis to shape the screw, and threading operations are done using a thread-cutting tool.

CNC machining has the advantage of producing complex geometries in parts along with tapped holes and screws, but Swiss screw machines are optimized for manufacturing threads and screws.

Many other factors differentiate CNC machining processes, like CNC turning from screw machining.

Precision and Accuracy

CNC machining is preferred for large custom parts requiring machining flexibility in different shapes. This means a feature like an internal thread can be easily produced on a CNC machine, making a custom part.

CNC turning for screws is highly accurate with CNC machining tolerances of up to 0.002” and CNC precision machining tolerances reaching ±0.0005”.

Swiss screw machining uses continuous material feed with guide bushing support near the cutting tool, which reduces vibrations and deflections, achieving tolerances of up to 0.0002”. Swiss-type lathes outperform general CNC machines in terms of accuracy and repeatability for high-volume micro-precision applications.

CNC Swiss machines have higher accuracy than CNC turning machines for small and high-precision parts with a superior surface finish and high repeatability.

Production Speed

CNC Swiss machining produces faster, more accurate, and highly repeatable screws, bolts and fasteners. This is because Swiss screw machines have multiple tools cutting simultaneously, while CNC fasteners produced on a lathe have a single cutting tool.

CNC Swiss machines have multiple spindles where different bars go through drilling and threading operations simultaneously, producing high efficiency and precision.

Try Prolean Now!

CNC Turning Vs. Screw Machining: Key Differences

TITLE: Swiss-type Lathe

The main difference between CNC turning and screw machining lies in workpiece handling and tool movement.

- CNC turning has a rotating chuck where the workpiece is fixed, while screw machines have a sliding head-stock with a rotating chuck

- Screw machines can perform simultaneous multiple-cutting operations on a single workpiece using different tool mounts, whereas CNC turning requires a tool switch.

- Once a screw is produced, another tool does a cut-off operation, and a new bar feeds automatically. In a CNC machine, the workpiece is loaded manually.

Materials For Screw Machining

Screw machining materials mainly include various plastics and durable metals, including non-ferrous metals, and this material’s versatility makes it useful to a wide variety of industries.

Aluminum

Aluminum is ideal for CNC machining and screw applications because of its lightweight strength, machinability, and excellent corrosion resistance.

Aircraft-grade aluminum is used in aerospace and military applications, and another benefit of using aluminum is heat-treatable aluminum alloys. Al 7075 and 6061 are popular materials for screw machining.

Stainless Steel

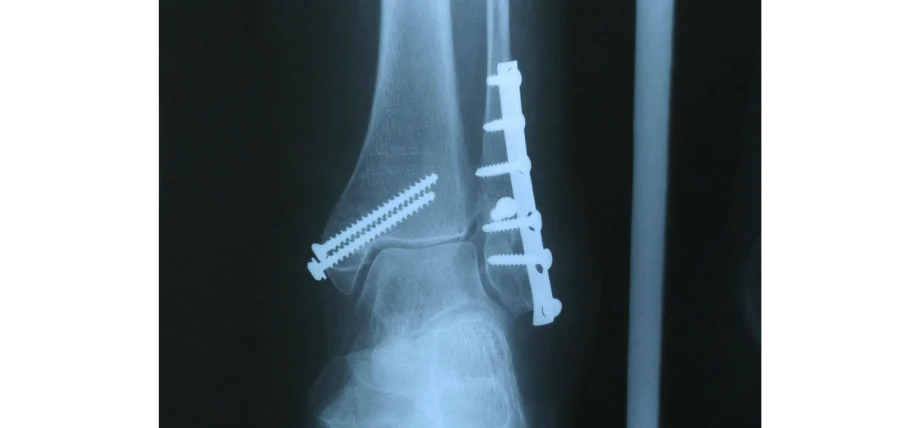

Stainless steel has corrosion resistance, heat resistance, and extra strength, which makes it ideal for marine applications. Many stainless steel alloys are biocompatible like 316 stainless steel making it suitable for medical screw machining in temporary fracture fixtures.

Brass

Brass has excellent machinability, which makes threading operations very easy. It has excellent conductivity, and brass fasteners, connectors, and terminals are made using Swiss CNC machines. Brass alloys like C360 offer easy cutting and reduce tool wear, making them ideal for screw manufacturing.

Carbon Steel

Carbon steel is a cost-effective alternative with high strength and durability. Carbon steel is mainly used in automotive and industrial applications. While not a popular choice for screw machining, it can be CNC machined to produce fasteners used in gear assemblies.

Titanium

Titanium is strong, lightweight, and unreactive, making it biocompatible for medical implants and bone screws. Titanium screws are also used in aerospace applications because of their high strength and heat resistivity.

Common grades like Ti-6Al-4V are preferred for their strength in durable applications, and medical grades like Ti-6Al-4V ELI are used in implants. Titanium is a common metal in precision manufacturing and custom dental implants.

Copper

Copper screw machining is mainly preferred for its electrical and thermal conductivity. Swiss machines use a guide bushing to stabilize the workpiece near the cutting tool, ensuring tight tolerances for soft metals like copper.

Plastic

Plastics make rust-free, non-magnetic, and cost-effective screw replacements for valve seats and electrical housings. Materials like nylon and acetal produce high-precision screws in automotive applications.

Prolean Tech specializes in crafting high-precision machined parts with various materials in any industry.

Try Prolean Now!

Applications of Screw Machining

Screw machining is used in applications requiring high precision, small diameter, and high-volume production of metal or plastic screws.

Medical CNC Screw-Machining

Medical screws require tight tolerances for proper fitting. A small hardware inaccuracy can cause device and implant failure. Plus, medical screws require ultra-smooth finish or passivated surfaces for sterility.

CNC Swiss machines are capable of achieving low roughness in their surface finish. Screw machines produce simple parts for orthopedic implants like cannulated screws and dental screws.

TITLE: Bone Screw

Electronics

Electronic devices utilize screw machining for electrical contacts, and Swiss screw machines can produce hundreds of identical electrical contacts.

Screw-machining of connector parts requires machining materials like PEEK for their heat resistance and aluminum and copper for a perfectly smooth surface finish, which aids heat conductivity in applications like radiators and tiny heatsinks.

Aerospace Fuel Components

The aerospace industry requires lightweight, high-strength fasteners and threaded parts for assemblies. CNC Swiss machines are ideal for prototyping aerospace fasteners and machining high-strength alloys like titanium, while high-volume production relies on cold forming.

High-precision components are also used in fuel lines and landing gears. Durable screws, bolts, and custom connectors in aerospace components require CNC screw machining.

Cost Factors in Screw Machining

Screw machining costs vary depending on the tolerance and your material choice. CNC machining costs can be high for low-volume productions, but it produces components that are exactly to specification.

- Part Complexity: More intricate features, internal threads, and smaller diameters require advanced machining and special tooling, which adds costs

- Surface Finish: If you opt for a surface finish like coating or anodizing your screws, this can result in additional costs

- Production Volume: Swiss machines are generally cheaper compared to CNC turning for screws because their production numbers are much higher, and they can perform simultaneous cutting processes.

Precision Screw Machining Service

Looking for high-precision screw machining services? Prolean Tech specializes in producing thin-walled components with tight tolerances and the highest quality.

Our CNC machining service crafts custom manufacturing solutions for every industry and tailors production to your needs.

Conclusion

Screw machines are capable of producing high-precision parts used across various industries, and these machines can produce threaded fasteners like screws efficiently. You can use these advanced machining techniques and the right material choice for your application.

Whether you use CNC turning services or Swiss screw machining, this process offers reliability for complex parts for high-demand applications.

FAQ

What is screw machining?

Screw machining uses a modern lathe with multiple spindles that can perform different cutting processes like drilling and threading simultaneously to produce highly precise parts.

What is the manufacturing process for screws?

Screws are typically manufactured via cold heading (to shape the head), thread rolling (to press threads into the shank), and secondary operations like drilling or milling for specialized designs.

What are the advantages of Swiss screw machining?

The advantage of Swiss screw machining is high precision and tolerances up to 0.0002 inches.

Which materials are commonly used in screw machining?

Screw machining commonly uses stainless steel, aluminum, brass, copper, and titanium, depending on the application. Brass, copper, and aluminum

What machines are used to make screws?

There are many types of screw machines, like multi-spindle screw machines, Swiss screw machines, and CNC screw machines. CNC turning can also be used to produce screws.

How long does it take to produce parts using screw machining?

Swiss-type screw machines using simultaneous multi-tool operations on a single spindle can produce small screws in cycles as fast as 10-30 seconds per part.

0 Comments