Engine efficiency and performance are critical concerns for car owners, part suppliers, and manufacturers. Muffler optimization through CNC machining services from China is one of the best ways to meet this need.

The muffler is often overlooked, yet it serves more than just a noise reduction function. CNC machined muffler system components result in a high-quality muffler system that enhances engine fuel efficiency, enhances exhaust flow, and reduces back pressure.

As a dealer or supplier of muffler system parts, you want to choose the best designs for optimum car engine performance. That requires a good understanding of how the muffler system works, the purpose of the muffler, the different options available, and so on.

Prolean Tech is excited to share important insights into the muffler in automobile design and manufacturing methods, as it outlines why local and overseas clients prefer the CNC machining company.

We are the best for precision machined high-performance muffler parts with rapid turnaround as fast as one day, tens of material options, and tolerances of ±0.0002″ (0.005mm).

What is A Muffler System And Its Relationship To CNC Machining?

In simple terms, a muffler is just as the name suggests. The purpose of a muffler is to muffle sound from the car’s engine. You will find the muffler in the exhaust section of the vehicle, usually at the rear. It could be located somewhere else based on muffler types.

That means the muffler and exhaust are related, but not the same. The difference between a muffler and an exhaust system is that the muffler is an advanced extension at the end of the exhaust system with noise-reduction and other functions.

While the muffler is part of the exhaust system, its function is distinct from other components such as the resonator. It primarily focuses on noise reduction and optimizing exhaust flow.\

It is typically cylindrical, square, or oval-shaped, metallic, and slightly broader or bulkier than the usual exhaust pipe. Similar to the car interior designs well-captured in this article,: A Complete Guide to Custom Car Interiors and Manufacturing, you are bound to find different car muffler designs.

A Car Muffler

It is designed to allow the passage of exhaust contents before they are released into the environment. As the engine generates the power needed to move the car, a range of sounds emerge from the exhaust valves.

There are thousands of pulsating sounds every minute. Without a quality muffler, this noise can be significant and a nuisance to people and the environment. So, engineers created a muffler to counter this challenge.

CNC machining from Prolean Tech ensures the precision and reliability of the muffler system’s various parts. Our advanced machining solutions guarantee tight tolerances and excellent performance for these parts.

For more on CNC machining, check our prepared guide: CNC Machining: Complete Process Explained.

How Does The Car Muffler Work? The Interesting Science Involved

The muffler’s working principle is based on the absorption, cancellation, dissipation, and reflection of sound waves. The typical muffler has an inlet pipe, an exit pipe, and chambers/passages. Because there are different kinds of exhaust systems, the specific design of each of these components can vary.

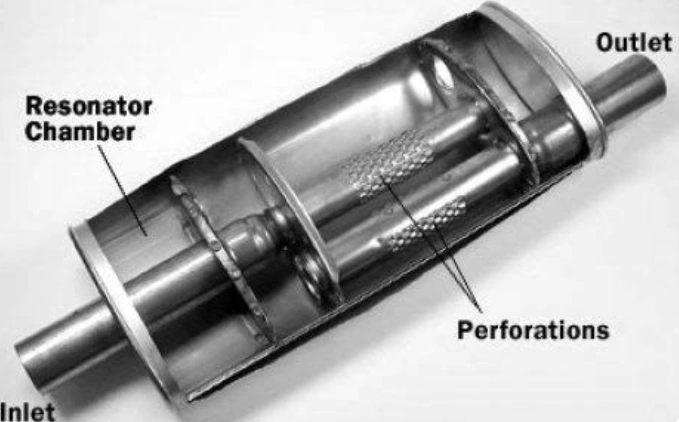

Different parts of a muffler in an automobile

Pressure waves expand, and some sound waves are reflected in the first chamber. As the sound passes through subsequent passages, the interaction of sound waves leads to cancellation.

Since energy can only change form and is never lost, the sound energy is converted into heat. The muffler walls have absorptive properties that enhance noise dissipation and eventual removal of the cooled gases at the exit.

So, the muffling of sound by this part is a combination of effects from design, materials, and perforations.

Precision-machined muffler parts guarantee superior noise reduction and engine performance. That’s why CNC-machined parts are critical for the muffler.

Of course, other engine performance factors exist including the engine valve. Check its relevance in Everything You Need to Know About Car Engine Valves.

Try Prolean Now!

Know The Different Muffler System Components for Better Selection

The question about the specific exhaust system parts and functions is worthwhile as you source the best muffler parts. Each muffler part affects the capacity to minimize exhaust noise, enhance engine performance, and last long while performing these functions.

Prolean Tech leverages CNC machining and other manufacturing methods to produce the most precise, usable, and durable car muffler components.

This approach also applies for other fundamental car systems like evidenced in this guide (Camshaft Guide: Types, Functions & Manufacturing Explained).

You can gain a competitive edge by understanding how each part contributes to top performance.

The main parts of the car muffler are;

Inlet Pipe For The Entry Of Sound And Exhaust Gases

This is the first part of the muffler from the engine exhaust system. It connects the muffler to the exhaust system and lets in sound and gases.

The Resonator Chamber for Sound Tuning and Optimized Flow

The resonator chamber is a special section of the muffler that you could also call the echo chamber. Its function is to cancel out sound waves and reduce the exhaust’s noise level.

Perforated Tubes Suppress Sound and Enhance Performance

Next in the muffler are the perforated tubes. These tubes guide the exhaust gases through the compartments of the muffler. The perforations are helpful for noise and back pressure minimization.

Perforated tubes

Baffles for Further Noise Suppression

A baffle is typically a porous insert in the muffler. Its primary function is to control the exhaust sound. The longer the baffle and the larger its holes, the more noise it can minimize while maintaining outflow.

Sound-Absorbing Material

The muffler contains sound-absorbing material or insulation to enhance the absorption and dissipation functions. In other words, these materials help dampen the exhaust noise. Popular materials for this include glass wool and mineral wool.

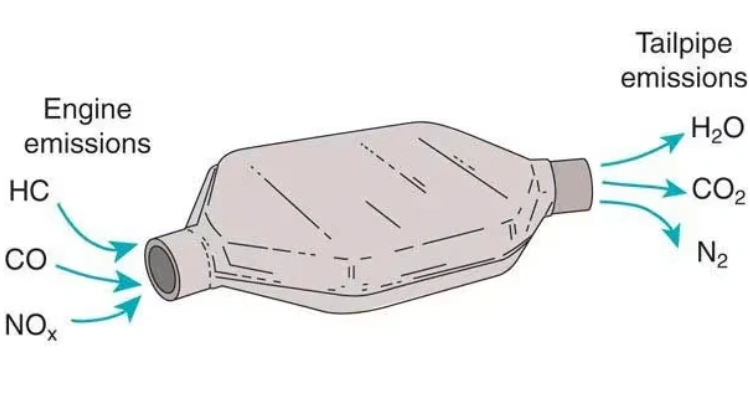

Catalytic Converter Minimizes Emissions

Catalytic converter process

Some muffler types come with a catalytic converter, a part that removes harmful exhaust elements. It converts the harmful elements into safer by-products before they are released into the atmosphere.

The Exit Pipe

CNC-machined end pipes

This is the point where the exhaust gases get released into the atmosphere. At this point, the muffler system has regulated and removed all harmful elements as required.

What Does An Exhaust Muffler Do, And Does It Matter For A Car?

As you look for the best muffler in automobile solutions, recognizing the main functions of this component may be helpful, particularly when choosing the most precise and durable machined parts.

Of course, the muffler mainly minimizes exhaust noise but also significantly affects engine performance and durability – elements that matter to car part manufacturers and suppliers.

Here are the main functions of the component:

To Control Exhaust Noise

As said, this is the most popular function of this component. The muffler’s design and parts help reduce exhaust noise. Sound-absorbing materials such as fibreglass are used for this.

Further sound reduction happens due to the expansion and slow-down of the sound frequencies in the expansion chamber.

To Enhance Engine Performance

Car mufflers are also important because they enhance the car’s overall performance. The muffler sucks in fresh air as it works hard to get rid of the exhaust gases. The higher the exhaust flow, the more fresh air is pumped into the engine.

To Promote Compliance With Environmental Regulations

Some countries and states have laws for sound and emission levels. To adhere to such rules, mufflers can be designed to silence the noise from the engine to acceptable levels.

Your Material Options For Car Muffler Manufacturing And Their Considerations

If the material for the muffler matters, yes, it does – It affects the cost-effectiveness, durability, and overall performance of a muffler part.

The overall suitability of the material can determine the level of confidence users have in the mufflers, reiterating the importance of expert material selection and precision CNC machining.

Every material has strengths and weaknesses, so consider consulting CNC machining experts and design engineers at Prolean Tech for the best muffler material for your situation. We have worked with 80+ materials in countless projects and have experience in many related systems including crankshafts: types, function & manufacturing.

Our certified and experienced engineers are willing to offer advice regarding how to use muffler materials, including the following.

Stainless Steel In Corrosion-prone Areas

Mufflers made from stainless steel have superior corrosion resistance and perform flawlessly for years.

Although this type of muffler may be a little pricey, it is worth the investment if you live in a humid environment. It also suits drivers on snowy roads that are regularly treated with salt.

Stainless steel muffler

Aluminized Steel for Affordability and Durability

Aluminized steel is a popular material for mufflers. This material is made by applying a coat of aluminium-silicon alloy on mild steel. The aluminium offers the much-needed corrosion resistance while the silicon aids in adhesion.

Other Materials – Composites, Titanium, Mild Steel, etc.

Apart from metal, other materials like rubber can make the muffler. Rubber can be used when the car needs to absorb and insulate the sound at a higher level.

A titanium muffler is an option for low-weight and strong mufflers, particularly for high-performance cars. Due to its high cost, the material is usually popular in high-end markets.

Titanium Muffler

Mild steel mufflers are budget-friendly and easy to work on, but their proneness to corrosion and rust is challenging in many situations.

Corroded muffler

Try Prolean Now!

Note the Manufacturing Processes for the Car Muffler

Another question a muffler manufacturer or dealer may wonder about is the manufacturing methods for the product. There are different ways to produce the muffler.

Prolean Tech can manufacture a muffler from scratch because we have over 80 advanced manufacturing processes. We are thorough at it the same way we handle shafts, as covered in Motor Shaft Guide: Types, Materials & Manufacturing Explained.

The main processes for the product are;

CNC Turning and Milling to Precise Shapes and Sizes

Precision CNC turning applies to the cylindrical parts of this system, including the inlet/outlet pipes and resonator chambers. Our turning processes ensure exact specifications for wall thickness and surface finish. We produce these parts to the most precise tolerances.

We use the same technique for a car’s transmission shafts and other cylindrical parts. You can read more about the transmission shaft here: Transmission Shaft Explained: Types, Parts & Manufacturing Guide.

CNC machining through milling is also applicable in muffler production. It is an excellent production method for complex shaped parts like baffles. CNC milling would be a preferred technique if you have custom muffler requests involving slotting.

You can order CNC-turned and milled muffler parts from Prolean Tech, the provider of the leading CNC machining services.

CNC Metal Forming – Bending, Hemming, With Press Brake

Forming a sheet metal fabrication method entails manipulating the part without removing any material. This technique is applied where joining, extra strength, or durability is required.

A good example is sheet metal bending, which entails the application of controlled force to expertly transform sheet metal into predetermined shapes. Sheet metal bending produces mounting flanges, muffler caps, and muffler casing.

Our CNC press brake machines have multiple axes for precise and repeatable forming performance. The machines have adequate tonnage to handle any material regardless of hardness and thickness.

They also have different tooling setups for all the custom CNC metal bending and hemming requirements.

If you need CNC metal forming services for your muffler parts, ask for a Fast & Free Quote today.

Welding for Superior Joints

Custom muffler welding is another manufacturing process for muffler production. It applies where you want to join different metallic muffler components.

There are different welding techniques to choose from depending on the type and material of the muffler. For instance, aluminiumaluminum and stainless steel work perfectly with TIG welding. The pipes, muffler casing, baffles, and perforated tubes are usually welded.

Welded joints in a muffler

CNC Cutting for Accurate Clean Edges

No production process produces better cuts on the muffler than CNC cutting using advanced techniques like laser and water jet cutting. CNC cutting is a preferable technique for the manufacture of outer casings for the muffler, and even other car system components such as car suspension parts & systems.

Laser Cutting

CNC Drilling – Accurate Holes for Muffler Components

Another process applicable in the production of mufflers is CNC drilling, for instance, for the mountain brackets.

Muffler mounting bracket

Conclusion

We have outlined the basics of the exhaust system parts and function, focusing on the muffler. With this background, you can confidently survey the market for the best CNC machining company.

When you are ready for this next and crucial step, you can count on Prolean Tech to offer a dependable hand. Our manufacturing processes suit high-performance and standard muffler solutions.

We can serve custom and mass productions because we have the most versatile setup for this type of manufacturing requirement anywhere.

With partners locally and overseas, you shouldn’t hesitate to start the conversation at any time. You can Reach Out Now for the best CNC machining services for your muffler requirements.

FAQs

What are mufflers made of?

Mufflers are made of stainless steel, aluminized steel, and titanium for durable performance.

What materials for car mufflers best suit high-end vehicles?

Titanium is the most suitable material for mufflers in high-end vehicles.

How much does a car muffler cost?

The cost of a muffler is relative depending on the customization, region, and material used. Prolean Tech produces cost-effective muffler parts.

What are the symptoms of a bad muffler?

A bad muffler has symptoms such as unusual sounds, visible damage, reduced engine performance, and excessive smoke.

What is the life expectancy of a car muffler?

The life expectancy of a muffler varies depending on different factors including material, environmental conditions, and level of maintenance. Mufflers from Prolean Tech are built for durability and can last well for over a decade.

0 Comments