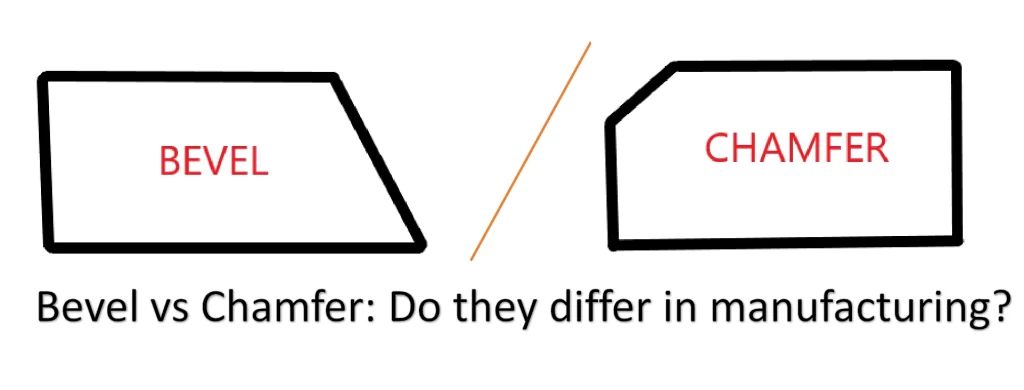

Bevel vs Chamfer

Edge modifications using chamfering and bevel machining techniques are common in different types of machining, metalworking, and other manufacturing processes. These techniques serve comparable functions, for instance, removing the sharp edges of a material for safety. However, they also have distinct characteristics that influence applications.

As you start your next CNC machining project, you may want to look at the relevance of each of these cuts closely. As you will discover, bevel and chamfer cuts may not always be interchangeable.

The usefulness of these cuts becomes evident when high-quality CNC machining is performed by a reputable company like Prolean Tech. We continue to provide top CNC machining services with a lean manufacturing approach, staying true to our name.

Let’s review chamfer machining and beveling meaning in detail so your upcoming projects are more aesthetic and functional.

What are Beveled Edges? A Key Feature for Stronger, Safer, and Attractive Designs

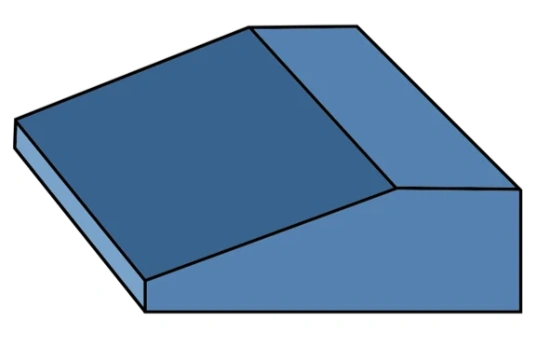

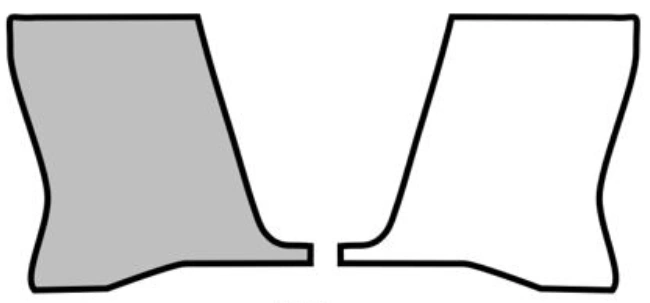

A bevel edge is an edge cut at an angle other than 90 degrees to create a sloped transition between two surfaces. The new angle can be anything, but it is usually 45 degrees. Some types of machining work with a 30-degree bevel while others can go the other extreme of about 70 degrees.

Beveled edge

The machinist can bevel to any depth or width depending on the prevailing requirement. The flexibility of executing beveled edges extends to the type of cutting tool for the exercise.

As explained in our detailed guide of bevel machining, popular tools for bevel machining are CNC lathe, grinding machine, and milling machine. A more dedicated option would be a special machine specially designed for bevel machining.

Know Tthe Categories Of Beveled Edges for Better Design and Cost Efficiency

When manufacturing components, Prolean Tech often uses beveled edges. The style, size, and location of the beveled edges vary greatly. The design intent, type of material, and user specifications can all influence the type of bevel used.

Bevel edges can come in different varieties that serve different functions. Here is a breakdown of a few of these categories:

Plain (single) Bevel/ V-Bevel

These are common types of bevels characterized by a constant slant angle and width. These bevels can be for cosmetic or functional purposes. When two of these edges meet, they form a V-bevel.

As the name suggests, the profile of this bevel edge forms a ‘V’. The common angles for this bevel are 30°, 37.5°, and 45°.

A V-Bevel

Compound (double) Bevel

A compound bevel

The other name for a compound bevel is a double bevel. That’s because this type entails two sloping edges that complement each other. This type of beveling is visually appealing in machined metal parts. You will mostly find it in cutting blades and precision-machined parts.

J-Prep Bevel

A J-Preb Bevel

The J-prep bevel is also called the J-groove bevel because its shape resembles the letter ‘J’. This type of bevel edge is often for the preparation of a butt weld.

Try Prolean Now!

What is a Chamfered Edge and Why Does It Matter in Manufacturing?

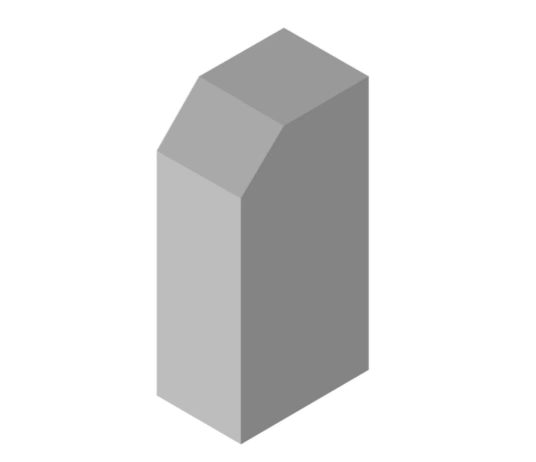

For a chamfered definition, the idea is to create a transitional edge between two surfaces, typically cut at a 45-degree angle, to facilitate assembly, reduce stress concentrations, and enhance safety. Often, the chamfer angle is 45 degrees, but it could differ depending on the project requirements.

A chamfered definition refers to the removal of a sharp edge, creating a smooth transition between two surfaces. Typically, the chamfer angle is 45 degrees, though it can vary depending on the specific requirements of the faces.

A chamfered edge

Chamfered edges are very popular in manufacturing for aesthetic and non-aesthetic purposes. When the sharp edge is removed, the part is safer for users and less interfering with the adjacent components. Chamfer machining is important in the assembly of parts.

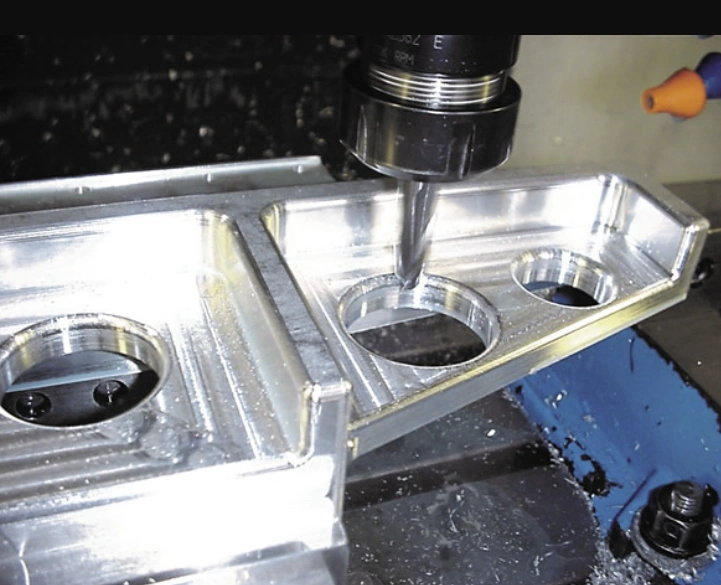

An end mill for chamfer machining

What are the Types of Cchamfer to Consider for Manufacturing?

If you are asking this question, you are not alone. A chamfer appears simple, but this concept is behind several cut variations. Each of the types of chamfer has a specific function in a project. If you are unsure what variety to use, you can always consult the highly experienced team at Prolean Tech.

In CNC machining, the simple chamfer (45-degree edge) is the most common. However, there are varieties based on angle specification, varying depth, section of the component chamfered, and presence of steps (stepped chamfer).

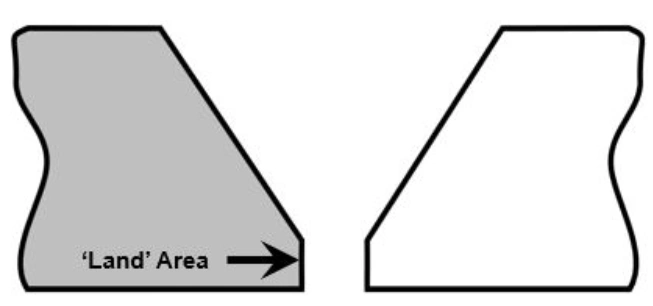

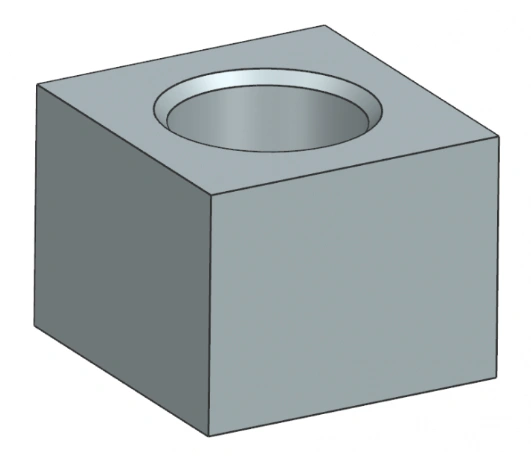

Internal Chamfer

This type of chamfer is performed on the inside edge of a component.

An internal chamfer

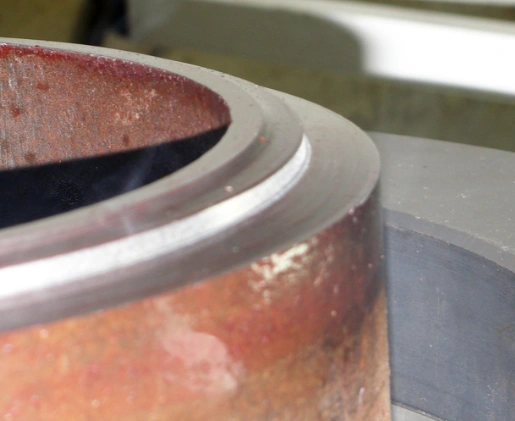

External chamfer

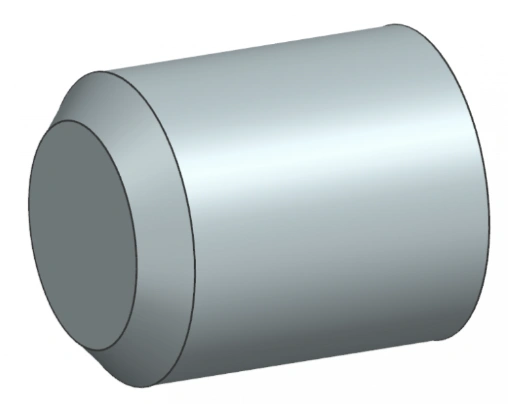

This is a chamfer on the outer edge of a component. The chamfer on the edge of the cylinder shown here is a good example.

A chamfered edge

It is noteworthy that a curvature to an edge creates a fillet. Read this comprehensive comparison of Fillet Vs Chamfer for more.

Try Prolean Now!

Is a Bevel and a Chamfer the Same Thing?

No, there are differences in terms of shape, areas of application, and even the results achieved by either of the cuts.

We often meet clients who are confused about beveled and chamfered edges, and where to use them. To be honest, there are some similarities between the two cuts, particularly the appearance. These similarities have come out so far in this discussion.

A fact we must agree on now is that using them interchangeably may not always work well. At Prolean Tech, we are very particular about which cut to use depending on the situation. We have worked on countless projects and are well-versed with the type of edges to use based on material type and other factors.

These comparisons of bevel vs. chamfer will further help in deciding between the two face machining techniques.

The Shape Difference

The shape here is about the angle of the cut. With a bevel edge, you can use any angle provided it meets the design requirements. Sometimes, the manufacturer has a predetermined angle before producing a beveled edge.

For a chamfered edge, the 45-degree edge is common. This is not to say there can be no variations, but this is often the standard in metal CNC machining.

Would you like to learn more about CNC machining? Discover the CNC machining process, its benefits, and applications—learn how it ensures precision and efficiency in modern manufacturing!.

The Cut Design Motivation

Bevels and chamfers can be professionally applied to control mechanical stress, aesthetics, and other aspects. Incorporating chamfered edges on gears helps reduce stress concentration and the likelihood of chipping.

Chamfered edges on a gear

Chamfers on fasteners ease insertion in the chamfered holes. Chamfers for counterbores are crucial for the flush-fitting of components. Chamfering is also applicable in enclosure edges and shaft ends.

As for bevel edges, we have many uses related to enhancing various aspects of design and manufacture. For instance, these edges increase the surface area for sealing and provide a flawless transition in assemblies, among other things.

For instance, chamfer edges can be introduced in machining to ease assemblies, particularly where shafts or fasteners are involved.

For the jewelry industry, chamfers enhance the aesthetics of rings and other items.

A chamfered-edge ring

These designs are also essential in relieving stress along the edges of a material. This is important because loading in such areas can cause cracking and eventual failure.

Chamfering is also essential for surface finishing the hard-to-reach corners of a component. Other reasons to use chamfered edges are enhanced machining effectiveness and sustaining the life of cutting tools.

Beveled edge designs can also be used for safety, stress relief, and ease of assembly. However, these designs are also instrumental in enhanced load distribution, welding preparation, and functional geometry.

Beveled edges for weld preparation

Structural Stability

Yes, the structural stability of bevel and chamfer edges differs, but it all depends on the project specifications.There are instances when a chamfer offers more structural stability, while a bevel is the better option in others.

For instance, bevel edges are preferable for their improvement of joint integrity in welding applications.

Cost of Production

The cost of a machining process can differ depending on whether you use chamfers or bevel edges. Chamfer machining is a fast process that you can execute easily. It is usually a matter of cutting a section of an edge at 45 degrees.

However, beveling can be more complicated because the angles can vary. The need for precise control and accurate measurements makes the cut more demanding. The net effect of the extra requirements is a higher production cost.

How to measure bevel vs. chamfer cut

It is important to measure bevels and chamfers, but the motivations and approaches may differ. For beveled edges, the focus is usually on the sloping surface angle. Other cut specifications such as depth and width can also usually be included.

Measuring a chamfer cut is usually about specifying the linear dimensions with less concern about the angles. Machinists use special tools to measure the depth and width of the cut.

The tools for measuring these cuts include a bevel protractor, chamfering ruler, and chamfer gauge. Consult with our industry specialists to learn more about the differences.

Bevel vs. Chamfer: How to Choose the Best One for Your Products

It does not matter the material you are using or the level of dimensional accuracy; Prolean Tech can guide you on chamfer machining and beveling, thereby adding value to your projects. Our highly experienced engineers will offer custom suggestions to make your project successful and cost-effective.

Your project’s requirements should largely dictate your choice of either bevel or chamfer. If the quality of the bonding between surfaces is the priority, then it is better to use a bevel edge.

Chamfered edges are more about removing sharp edges for added safety and enhanced access. You can use this edge if that is the priority of your project.

Checking if your budget aligns with any of the cuts would also be advisable. Considering that the benefits are also compelling, it is important to perform a cost-benefit analysis first.

For more clarity, check out the comparison table below:

|

Factor |

Bevel |

Chamfer |

|

Part assembly |

Useful for precise mating of surfaces for assembly and welding |

Excellent in aligning and fitting angled edges |

|

Aesthetics |

A bevel can enhance the visual appeal of an edge |

A chamfer makes an edge appear more professional with an overall better appearance |

|

Machining difficulty |

More difficult to machine because precise angles and depths may be required |

Easier to machine, particularly in high-volume production |

|

Stress distribution |

Effectively reduces stress concentrations by smoothly transitioning surfaces |

Less helpful in stress distribution |

|

Machining cost |

Usually more expensive to produce a beveled edge due to angle requirements and more surface affected |

The cost of chamfering is usually slightly lower |

|

Effect on flow dynamics |

Offers a gradual surface angle that can improve flow in some instances |

Minimal effect or improvement on flow dynamics |

Would you like to explore how CNC machining services help start-ups streamline production, reduce costs, and bring innovative designs to life? Prolean Tech is ready to help.

Conclusion

That’s it! Both bevel and chamfer have their place in the best CNC machining processes. We have looked at chamfering and bevel edge meaning, their striking differences and applications, trusting that you have gained useful insights for your next project.

Your CNC machining will perform better if you use these cuts in their ideal situations. They also serve the same functions sometimes, for instance, concerning part aesthetics. You can use these techniques in every industry, from automotive to general manufacturing.

A team that is conversant with different sizes and types of machining is the best partner for beveling, chamfering, and all the other types of cuts.

Prolean Tech is ready to take your CNC machining services to the next level. Contact us today to book CNC machining services from China and kickstart the exciting journey.

FAQs

Are chamfers always 45 degrees?

No, chamfers and not always 45 degrees, but this is the most common angle.

What is a rounded bevel called?

A rounded bevel is a fillet.

What is the purpose of beveled edge?

A beveled edge has several functions including reducing sharpness for safety and enhancing the structural integrity of the part.

Which term is commonly used for bevel and chamfer?

The common term for bevel and chamfer is edge break, which means that the sharp edge has been broken by flattening or rounding off.

What angle is a chamfer usually?

The angle for a chamfer is usually 45 degrees.

What is the bevel rule?

The bevel rule, also called bevel gauge, is an adjustable tool for measuring bevel angles.

What is the most common bevel?

The most common bevel is the plain type at 45 degrees.

Does a chamfer have teeth or threads?

No, a chamfer does not have teeth or threads. Instead, it is a smooth slanting surface.

Is a chamfer an edge or corner?

A chamfer is an edge that replaces a sharp corner for aesthetic and non-aesthetic reasons.

What tool is used for chamfering?

The chamfering tool is ideal for chamfering, but there are alternatives such as the deburring tool, end mill tool, and countersink tool.

What is the correct bevel angle?

The correct bevel angle is different from project to project. For instance, in typical CNC projects, the most common bevel angle is 45 degrees. For welding projects, the correct bevel angle is 37.5 degrees.

0 Comments