Custom car interiors are changing the automotive industry. They combine precision, durability, and innovation. Businesses need custom solutions for their design and performance needs. Advanced techniques ensure high quality and efficiency.

They may apply to car interiors like dashboards, door panels, and many other parts. Custom manufacturing enables innovation and precision. It must blend functionality with beauty. It should withstand the daily wear and elements.

Making custom interior parts is vital for industries where the interior parts of a car must meet exact specs for luxury, safety, and performance. Manufacturers investing in custom interiors means offering enhanced luxury and performance.

Rapid prototyping and injection molding are used to make durable car interior parts like door panels and customized designs for these markets.

If your business needs custom car interior parts, ProleanTech can help. It streamlines production with cost-effective solutions and high strength injection molding guide with low-cost and versatile finishing options. Our team has the best custom car interior ideas. We use advanced manufacturing techniques, like CNC machining services. Custom car interior manufacturing adds value at every stage of the automotive lifecycle.

They use luxurious leather upholstery and advanced infotainment systems. They also use lightweight, durable components like sheet metal services. ProleanTech can meet your sourcing needs. We handle both mass production and custom car interior modifications.

This article covers custom car interior manufacturing. It covers the key interior parts, types of car interiors, and the latest techniques for car interior customization.

Basic Interior Parts of a Car

Basic Interior Parts of a Car

The interior part of the car is where its practicality, comfort, and aesthetic value are truly defined. Each part has a purpose and works together to make driving fun. Custom car interior manufacturing industries must comprehend these components and provide value. Industries want customized car interiors. This knowledge is key to creating value.

1. Seats

Seats of a Car

Seats are one of the most important car interior parts names. There are standard bench seats, ergonomic bucket seats, and sporty, supportive versions. Leather, durable textiles, and memory foam inserts can be added for comfort and style. Brands may differentiate their cars and improve consumer pleasure by offering customized seats.

2. Dashboard

Dashboard of a Car

The dashboard is the vehicle’s central hub. It has key features like control panels, instrument clusters, and infotainment systems. It’s a design focal piece. It often features customizable wood, carbon fiber, or aluminum accents. Custom dashboards reflect the vehicle’s identity and functions. They give an edge in competitive markets.

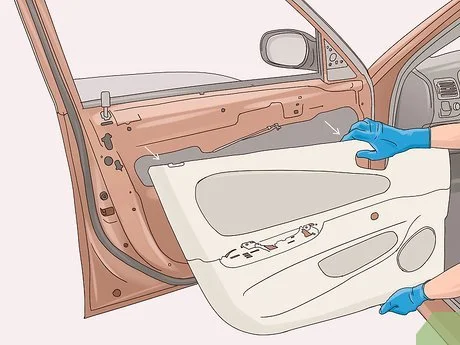

3. Door Panels

Door Panels of a Car

Door panels house important controls for windows, locks, and integrated sound systems. They also improve vehicle insulation and acoustics. Businesses may use high-strength polymers or soft-touch textiles. These can improve functionality and comfort. They also create unique selling features.

4. The Headliner

The Headliner of a Car

The headliner, or ceiling cloth, is usually unseen. But it greatly impacts a car’s interior. Luxury car versions might have high-quality suede or Alcantara upholstery leather. Custom manufacture adds refinement to vehicles with noise insulation or integrated lights.

5. Carpets and Floor Mats

Carpets and Floor Mats

Car floor mats and carpets not only protect floors but also add elegance to vehicles. Waterproof mats, stain-resistant materials, and logos designed for cars are all customizable options. These qualities are essential for automotive businesses that aim for class and longevity.

6. Pedals Control

Pedals of a Car

A car’s design is efficient. It shows how drivers use its pedals and controls. The location of the pedals and the reaction time affect how the vehicle feels when driven. A perfect example of combined technologies is the clutch pedal in manual cars.

It’s like the brake-by-wire system in electric ones. It also takes into account the location of the controls, gear change, and steering wheel.

A brand’s identity or the demands of an industry can be met by customizing each interior portion. Having a family automobile that is easy to clean and with safety features for kids can be a lifesaver. Lighter materials and more ergonomic designs could help sports car manufacturers boost performance.

Businesses can optimize their designs for their target audiences. They can do this by working with car interior manufacturers to be efficient and cost-effective. Rapid prototyping and material analysis make these components durable, practical, and attractive. Customizing car interior parts names, seats, and dashboards helps businesses succeed in competitive markets.

Try Prolean Now!

Types of Car Interior

Types of Car interior

There are types of car interiors that are the most demanding and appealing. They must meet industry standards. Different styles combine practicality and design to improve driving.

Luxurious Interior

Luxurious Interior of a Car

Luxury interiors are sophisticated. They use premium materials like leather, natural wood, and brushed metal. Heated chairs, ambient lighting, and smart temperature control systems provide luxury and relaxation. Advanced techniques, like CNC machining and injection molding, often craft these interiors.

They are ideal for luxury vehicles and premium brands. CNC machining makes precise trims. Injection molding makes durable, intricate components. Luxury interiors are ideal for luxury cars and companies.

Tech-Enabled Interior

Tech-Enabled Interior of a Car

Tech-integrated interiors offer cutting-edge connection and infotainment for tech-savvy drivers. Common interior features include large touchscreens, wireless charging stations, and voice-controlled systems.

Augmented reality (AR) displays, adaptive ambient lighting, and smart temperature management are widespread. 3D printing creates custom car interior parts and control panels and also ensures innovation aligns with functionality.

Sporty Interiors

Sporty Interior of a Car

Sporty interiors focus on the performance and utility of sports cars. They use lightweight materials, ergonomic seats, and a simple design. Carbon fiber and Alcantara are utilized to minimize weight and retain durability.

Bucket seats, bright colors, and sporty steering wheels add style. Injection molding and CNC machining are vital for making durable, lightweight parts. They ensure the interiors are both beautiful and high-performing.

Choosing Custom Car Interior Manufacturing Material

Custom interior automobile parts’ quality and appearance depend on their substance. To ensure longevity and functionality, utilize high-quality automobile interior materials, whether metal or plastic. We’ll examine interior automobile part design materials and components below.

Metals

Metals and alloys are still used in automobile interiors, even if there are fewer of them. The brake and accelerator pedals, shift knobs, door panels, and accent trims are common areas to find this material used. Car chassis provide support and safety. They also affect the design and materials of the interior.

This is to ensure compatibility and performance. Common materials used for these components include aluminum and steel. Customized shift levers in high-end vehicles can be made of titanium.

Due to its low density and malleability, magnesium is an ideal material for use in seat frames and brackets. When used correctly, these metals improve the visual appeal of automobiles.

Material made of plastic

Plastic is a common material inside cars. Internal car parts can benefit from these polymers’ low cost, long lifespan, machinability, and personalizability. Below is a list of common polymers that are utilized in car upholstery.

Door panels and dashboards both make use of ABS.

Interior door panels: Polypropylene (PP).

Internal lighting panels and components are polycarbonate (PC).

Polyurethane: Armrests, headrests, and other cushions.

Polyethylene (PE): Car storage and trim.

Leather, Vinyl

Leather and vinyl are popular for automobile seats, gear changes, and steering wheels. They improve ergonomics and add luxury to the car’s interior. Alcantara is another suede-like fabric used for headliners and seat inserts. These synthetic automobile interior materials are easy to maintain and improve look.

Wood

Wood is unusual in vehicles; however, premium car interiors may use it. Dashboards, steering wheel inserts, and trims might be customized designs. They warm up the car’s interior while looking vintage.

Composites

Automotive composites like carbon fibers are popular due to their benefits. They have a high strength-to-weight ratio and give the automobile a premium look. Due to its high cost, it is usually used in luxury cars. These composites make interior automotive parts like door panels, trim, and seat backs.

Try Prolean Now!

Manufacturing Techniques and Technologies for Custom Car Interior

Successful car interior modification requires advanced manufacturing techniques. They enable businesses to deliver precision, durability, and innovation. These technologies create custom designs and components for specific needs. They ensure competitiveness in the market. Let’s explore these techniques in detail:

CNC Machining

CNC machining Visuals

CNC machining is an essential tool for accuracy in manufacturing. Dashboards, control panels, and trims are some of the most detailed parts inside that obtain advantages from their use. Consistent quality and accuracy are achieved by manufacturers through the use of computer-controlled machinery.

Techniques such as CNC Machining cutting speed and feed rate optimization perform a unique role in ensuring precision. Their goal is to minimize waste while retaining high-quality output. Due to this, they are perfect for companies who want to save money without sacrificing performance.

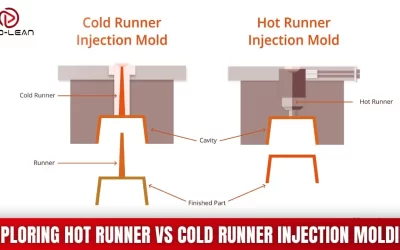

Injection Molding

Injection Molding

There are many applications for injection molding. It produces long-lasting parts for automobiles’ interiors, such as door panels, consoles, and storage areas. Complex, custom-finished pieces may be produced in mass quantities using this method.

Companies may provide value with the use of inexpensive materials and high-strength injection molding. This doesn’t have to mean compromising on style or quality.

Sheet Metal Services

Sheet metal Services

Sheet metal services are vital for making strong, lightweight parts for car interiors. This method is common for parts like seat frames and supports. Advanced sheet metal services can help manufacturers. They ensure components are strong, durable, and lightweight. This is vital for sporty, energy-efficient vehicles.

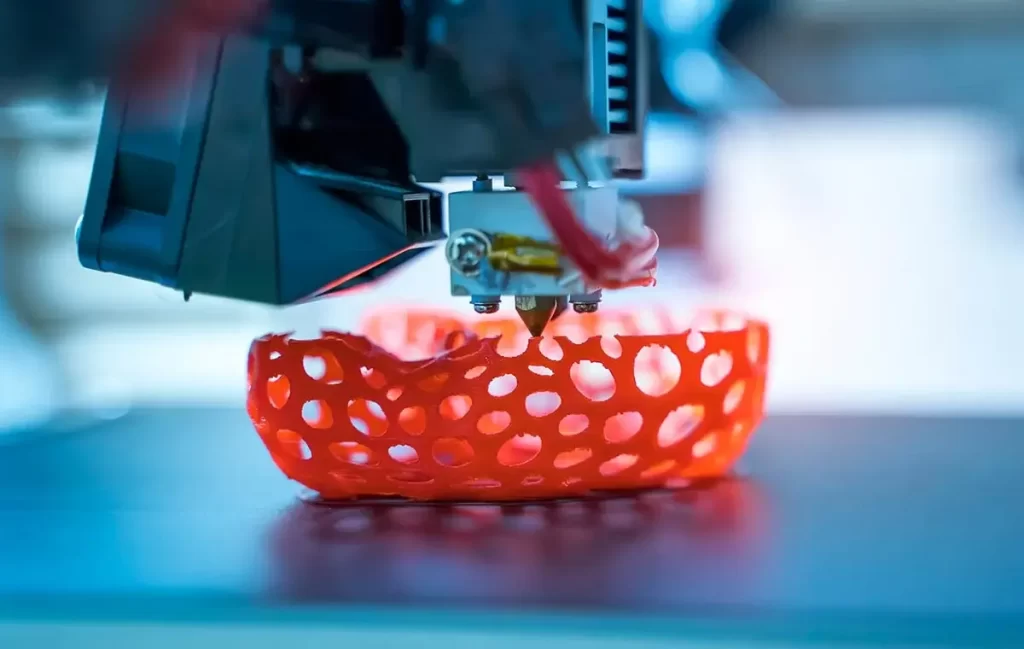

3D Printing

3D printing is changing car interior mods. It allows for complex, custom parts. This tech is ideal for unique custom design elements, like decorative trims, vents, and accessories. 3D printing can handle fast iterations. It lets manufacturers meet client demands quickly and cheaply.

ProleanTech uses advanced methods and years of expertise. We help businesses achieve peak efficiency and quality. ProleanTech will complete your projects on time and within budget. We make precision components with CNC machining.

Advantages of Custom Car Interior Manufacturing

Custom car interiors let you customize your vehicle. They boost comfort and style while reflecting your preferences.

Aesthetics

Aesthetics play an important part in customizing the interior of a car. Besides, this extends beyond just choosing materials and colors that coordinate. Remember to include intricate features, textures, and finishes that enhance the car’s look.

User friendly

Personalizing a car’s interior should prioritize comfort and ease of use. The goal is to make the driver’s control experience as smooth as possible, beyond just looks. A well-designed bespoke automobile may make driving better. Its interior should be pleasant, safe, and less distracting.

Efficiency

When personalizing your vehicle’s interior, balance between design and function. Improving the car’s features should make it easier to maintain and cater to the driver’s wants. This helps ensure reliability and allows you to enjoy the customized functionality for longer.

Car Manufacturers industries should consider ergonomics and aesthetics values. They should seek to use cutting-edge technology to improve the interiors of cars, especially their entertainment systems.

Try Prolean Now!

Conclusion

Custom car interiors give automotive businesses a competitive edge. They can deliver tailored solutions that boost performance and appeal. Businesses can now use advanced methods, like sheet metal services and CNC machining services.

They can optimize cutting speed and feed rate. This allows for unmatched customization. In car interior manufacturing, the right materials and methods improve quality and success.

ProleanTech uses CNC machining and injection molding to create high-quality, low-cost solutions to bring your designs to life. Start on an adventure towards upgrading car interiors.

Contact us and upload your design file. Our expertise can boost your industry’s success with high-precision car interior manufacturing solutions. Let’s explore custom, innovative solutions for your industry needs!

FAQs

Q.1 What manufacturing method is best for customizing car interiors?

CNC machining is better than 3D printing for making car parts. 3D printing can create complex, custom-designed accessories. However, CNC machining can precisely trim panels and make dashboard parts.

CNC machining and injection molding are best for making high-precision parts. They ensure quality and efficiency.

Q.2 How does material selection influence custom car interior parts design?

Material selection impacts longevity, comfort, and visual appeal. The design goal determines the material choice, which often includes leather, cloth, or carbon fiber.

Q.3 Can 3D printing create custom car interior parts?

Yes, 3D printing is great for prototyping. It can make lightweight, complex parts to fit specific designs.

Q.4 What are the most essential car accessories?

Essential car accessories include floor mats, seat covers, ambient lighting, and advanced infotainment systems.

Q.5 How much does it cost to replace the interior of a car?

The cost varies with the materials and design. It ranges from standard replacements to high-end customizations.

0 Comments