CNC machining is a subtractive manufacturing method that involves removing the material from a workpiece to obtain the designed shape. Different types of cutting tools are used for the material removal process. Here, the machining variables decide the characteristics of material removal and the quality of machined parts. CNC cutting speed and feed rate are the two most important variables, they directly affect the production speed, precision, chip evacuation, surface finish, and tool life. Therefore, considering their optimizations is essential for any CNC machining project.

This article will elaborate on their concept, importance in manufacturing, and how you can calculate feeds & speeds.

What is CNC Cutting Speed?

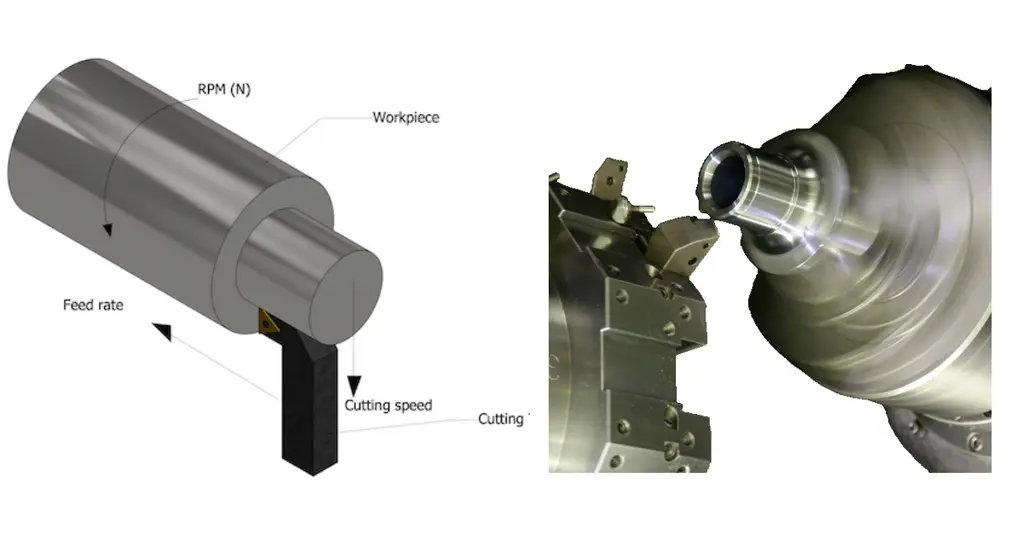

CNC cutting speed refers to how fast the tool removes the material from the workpiece. It is the distance the cutter moves along the workpiece surface in a fixed time, typically in one minute. The units are; m/min and ft/min.

From the unit, you can figure out it is the velocity of the tool relative to the workpiece. So, higher speed means higher chip formations due to fast relative motion concerning the workpiece surface. The fast cutting speed can reduce the production cycle time, but they cause rapid tool wear and shorter lifespan. If the speeds increase too much along with the feed, it can break the tool, especially with the hard workpieces.

Spindle speed is the rotational speed of the cutting tool or workpiece (RPM), whereas cutting speed is the linear speed at which the tool moves across the workpiece ( m/min, ft/m, inches/min).

How to Calculate the CNC Cutting Speed?

Cutting speed can be calculated using the formula:

Cutting Speed(v)=πDN/1000 m/min

Where:

D is the diameter of the cutting tool or part in millimeters,

N is the spindle speed in revolutions per minute (RPM).

Factors Affecting the Speed

- Machinability & hardness

- Tool Material and Geometry

- Stability of Machine

Try Prolean Now!

What is the Feed Rate in CNC Machining?

Feed rate refers to how fast the material is removed in a revolution of machining tools. It is expressed in mm/revolution and inches/revolution. For example, 2mm/ rev refers to the cutting tool traveling 2mm on the workpiece surface in one revolution. Meanwhile, you need to understand that here cutting depth is constant.

Cutting speed and feed rate

Sometimes, feeds are also expressed in terms of mm/tooth, which means how much length is being machined by cutting teeth.

In linear CNC machining processes ( like shear cutting and laser machining), it is expressed in mm or inches per minute.

How to Calculate the feed rate?

The feed rate of the CNC machining operation can be calculated with the formula below;

vf = n·z·fz

Where,

Fz is chip load per tooth A tooth certain thickness, next, and goes on

N is the Speed of the spindle RPM

Z is the number of tooth

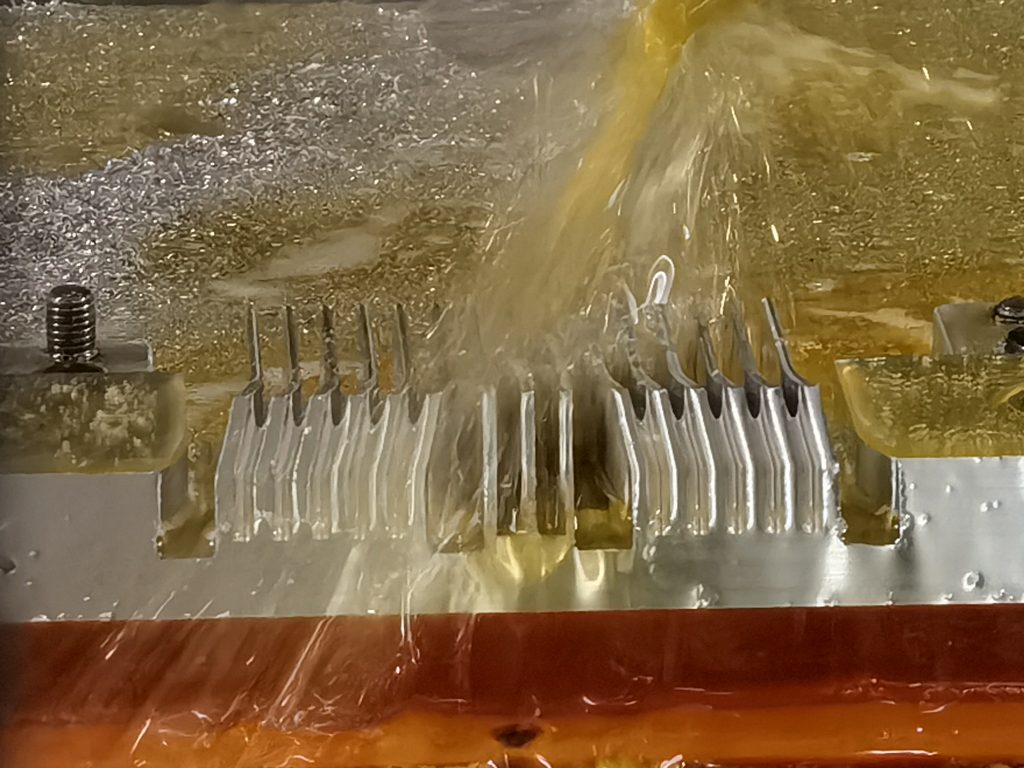

CNC machining and cutting fluid

Furthermore, You can use the CNC cutting speed and CNC feed rate calculator available online. There you need to simply put some information about the machining process and the calculator provides suitable feed and speed rate.

Factors Affecting the Feed Rate

- Tool and workpiece Material

- Depth of cut & how thick chip will be formed

- Tool Geometry

- Number of cutting edges or faces on the tool

Importance of Cutting Speed and Feed Rate In CNC Machining

Too slow and too-high cutting speeds negatively affect accuracy, precision, and tool life. If the cutting speed is too high, it can degrade the surface and even break the tool. On the other hand, the feed rate decides the roughness level of the machined surface. Feeding too much material beyond the spindle RPM limit ultimately breaks the tool wear, whereas a regular imbalance of CNC feeds and speeds causes the build-up and CNC machining tolerance. Especially, the effects can be seen more in harder materials, such as hardened steel, tool steel, incole, and titanium alloys. Because the hardness of any material is directly associated with its machinability, the higher the hardness, the lower the machinability.

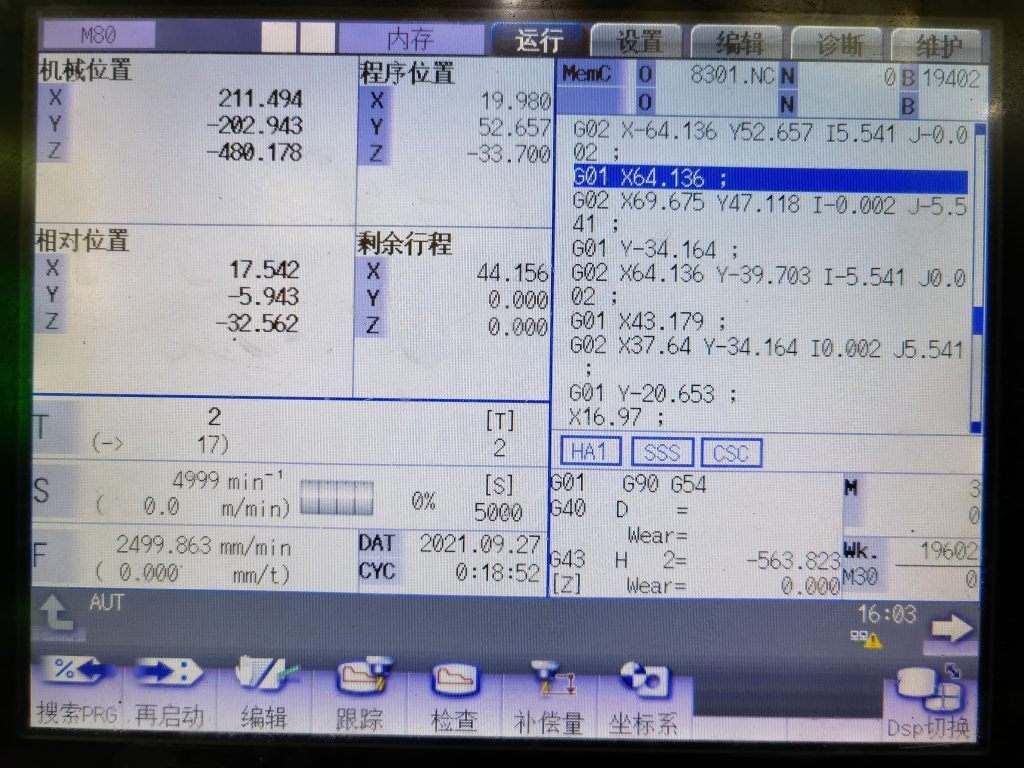

Feed rate and speed setup in CNC machine

The chart below shows the effects of the imbalance and the benefits of using the right cutting speed and feed rate;

| Cutting Speed(→) / Feed Rate ( ↓) | Low | Optimal | High |

| Low | Slow material removal and low tool wear | Slow removal rate, but smooth finish | Low efficiency, poor finish, tool wear |

| Optimal | Moderate removal rate, decent finish | Ideal efficiency, balanced tool life, excellent finish | High removal rate, tool wear, rough finish |

| High | High removal rate but high tool wear | Aggressive cutting, tool life compromise | Risk of overheating, poor finish |

Moreover, the actual values depend on several factors, machine capability, material type, complexity, and end requirements of precision machining.

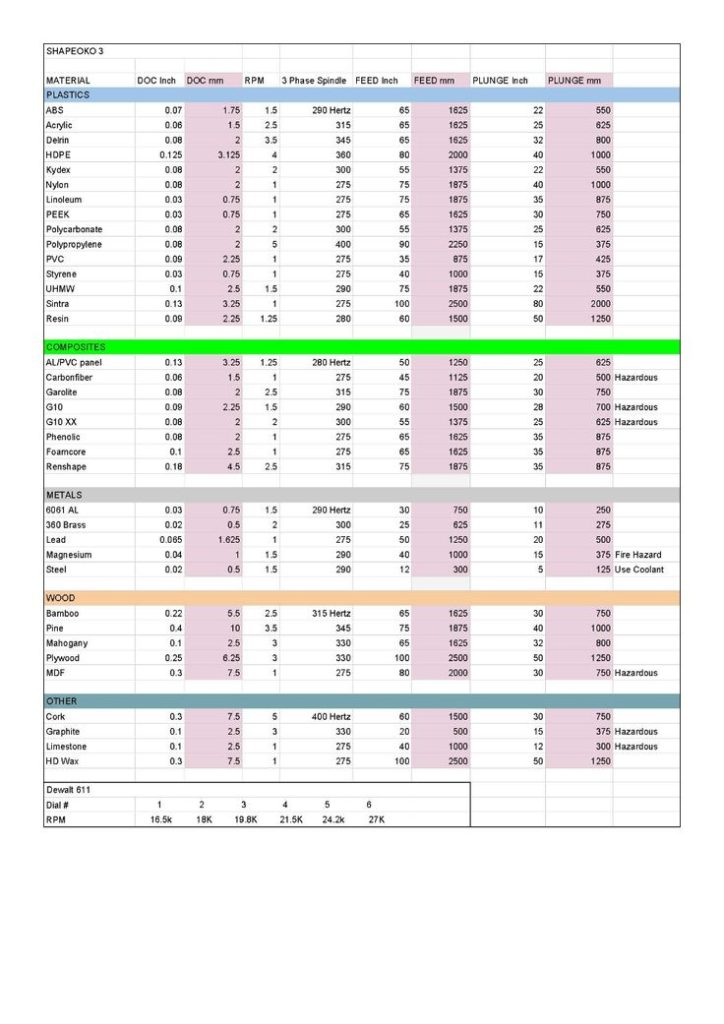

What is the CNC Feeds and Speeds Chart?

The feeds and speeds chart is a systematic table that includes feed rate and cutting speed for different tooling, work materials, and machining operations. Engineers and CNC operators use this chart to find the best possible values to achieve efficiency, prolong tool life, and achieve accurate results for any specific CNC project.

Here is an example of a typical CNC feed and speed chart;

Try Prolean Now!

Summing Up

Overall, the CNC feeds and speed are chosen based on the properties of the workpiece and tool material. They decide the precision, surface finish quality, and tool life in any machining operation. Typically, the harder material decreases the machinability and so the feed & cutting speed. On the other hand, there are minimal effects of their variation on softer workpieces.

At ProleanTech, our CNC machining service highly prioritizes the use of cutting speed and feed rates. Our engineers and operators have more than a decade of experience in this field, they analyze the requirements and optimize these parameters through several test runs on scrap materials. So, contact us if you are looking for any related solutions.

FAQs

What is the effect of cutting speed in an end mill?

High or low speeds affect the end mill’s performance by influencing the chip formation, surface finish, and tool wear. High speeds improve efficiency but may reduce tool life, whereas slower speeds cause rougher surfaces.

Are speeds and feeds co-related in CNC machining?

Yes, speeds and feeds are interdependent in CNC machining. Only optimal settings balance these to achieve desired machining results.

Which CNC tool can machine with high speeds and feeds?

Carbide end mills and insert cutters are commonly used for high-speed, high-feed CNC machining due to their high hardness and wear resistance.

What if my CNC machining parameters are inconsistent across the batches?

Inconsistent CNC parameters across batches can lead to variations in part quality, affecting dimensions, surface finish, and tolerances. This also increases the scrap rates and so the cost.

0 Comments