Molds are designed by part specialists who usually prepare job books that contain minute details of each molded part. As the mold manufacturing process has to be reasonable, unvarying, and effective, factories create their specifications and employ parts specific to their operations. Reading this article you will be able to familiarize yourself with the basic components of injection molds, their purpose, and the aspects you should be taken into account during production. Plastic injection molding is a sophisticated process and if the concepts like Runner Sprue, Water Baffle, and Ejector Pin are making you confused then you are not the only one. These mold components are explained in simple terms in this guide together with the roles of each part and how they carry out the entire molding process. This article explains 9 core injection mold components.

9 Key Injection Mold Components

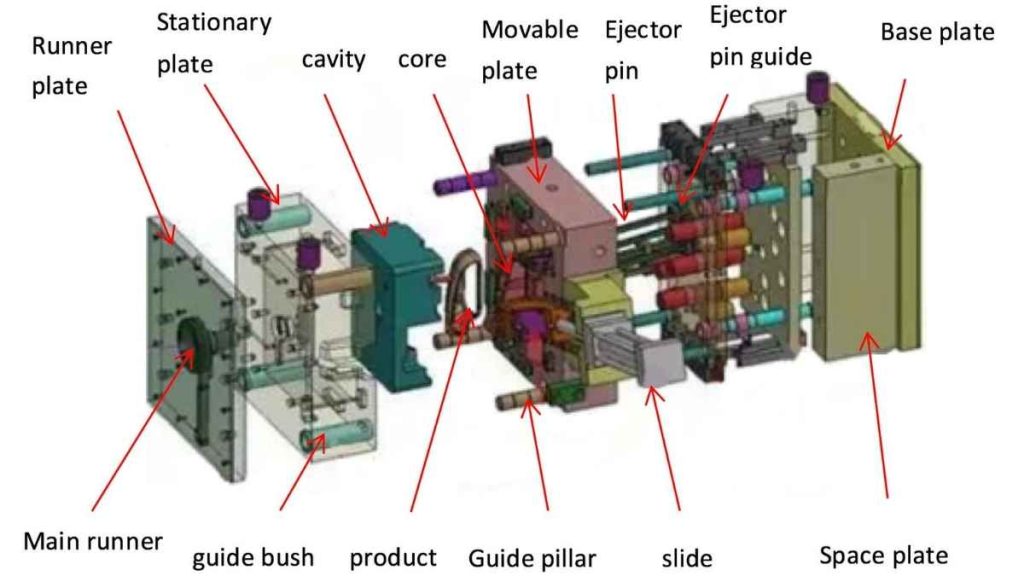

Injection mold components

The important elements that determine the success of the injection molding, process are the quality of the injection mold parts and their ability to perform the intended task. All the sections of the mold have their unique function in making certain the final plastic product has the right characteristics and performance standards. Here we explain the main components of injection mold design.

Try Prolean Now!

1. Mold Base

The mold base is the framework in which all other components of the injection mold are anchored and positioned. Typically, made of AISI 4140 steel or aluminum alloys, it is built to withstand the pressure and temperatures associated with the molding process. The mold base is made up of features such as cavity and core plates which are used to give the shape of the molded part, and as such they are accurately machined to give the exact dimensions.

Mold base

The mold base has guide pins and bushings to ensure that the two halves of the mold are in the correct alignment. Further, the mold base contains ejector pin holes through which ejector pins that remove finished parts from the mold cavity are inserted. Cooling channels incorporated into the mold base enable control of the mold temperature with the help of water, or other special fluids. These fluids manage the cooling rate and cycle time leading to a better quality of the end-use product.

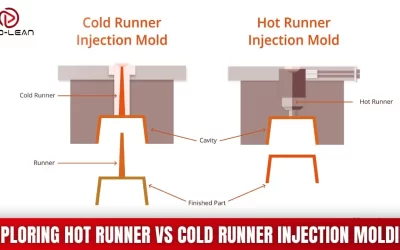

2. Runner System

Mold hot runners

The runner system plays an important role in delivering the molten plastic from the injection molding machine to mold cavities. The runner system consists of channels that start with the sprue connecting the machine nozzle to the mold. The plastic material from the sprue is directed through the runners which subdivide to get to each cavity. In this context, the design of the runner system is critical to ensuring equal distribution of material and reducing pressure losses. Modern-day runner systems include hot runners whereby the heated channels ensure that the plastic used has the right quality by minimizing waste and meet required standard. Cooling channels located often next to the runners help to manage the temperature of the plastic and improve the process of solidification and production in general.

3. Ejector Pins

Mold ejector pins

Usually, manufactured from tool steels such as D2 or H13, these pins are intended to endure the mechanical forces that go along with the ejection process. Ejector pins work by applying a certain force on the mold to remove the solidified part from the mold properly and safely. These pins are usually cylindrical with rounded or flat ends and the location and design of ejector pins depends on the part geometry and the mold design. Ejector pins should be checked and greased periodically to avoid cases like sticking or even being damaged. Because some of the pins may get worn out and may not be able to perform their function as expected, hence the need to replace them to avoid unnecessary breakdown of the production line.

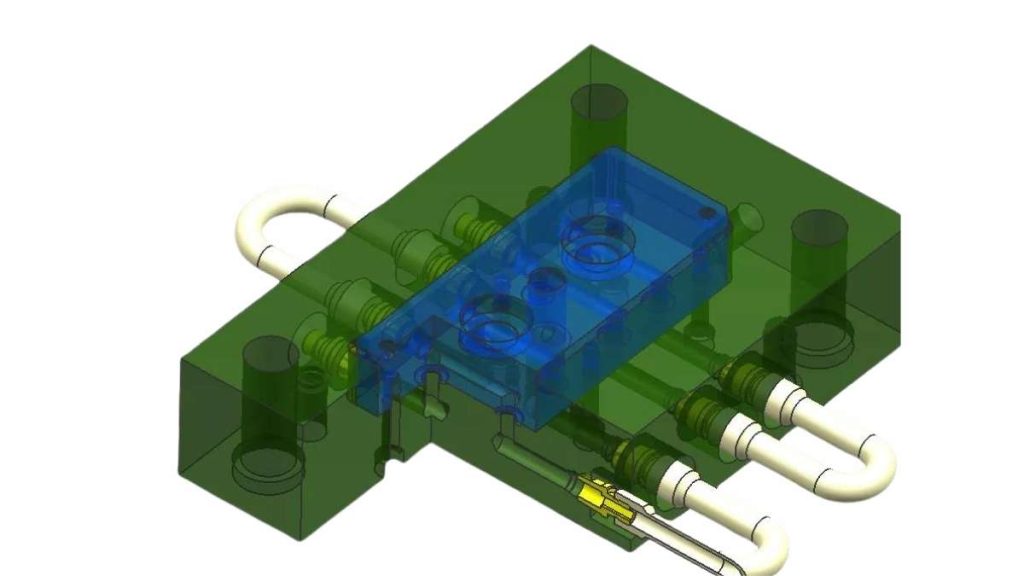

4. Cooling System

Cooling system in injection mold

Cooling systems are used in the process of controlling the temperature of the mold. It comprises of channel that has well well-designed cross-section through which fluids like water or oil used in cooling the mold are circulated. These systems help to extract heat from the molten plastic and simultaneously, foster the proper solidification process to occur. Appropriate cooling helps to avoid issues, and mold flaws such as warping and shrinking, due to equal distribution of heat. The channels are located to cool the metallic extensively as well as to improve the quality of the parts being manufactured. Cleaning and monitoring the flow of the system sound practices must be conducted frequently to achieve the needed level of system performance and get the desired results in production.

5. Guide Pins and Bushings

Guide pins in injection mold

Guide pins and bushing are critical components of the mold. These pins ensure the correct alignment of the mold halves and free movement between them. A pair of guide pins are provided in one half of the mold and there are corresponding bushes in the other half. So, the mold can be accurately aligned and cannot get misaligned during its operation. This setup reduces the resistance and achieves easy movement, especially important when preserving the parting line. These parts and components are expected to wear out with time and therefore, require frequent checks and replacements to guarantee the efficiency of the molded parts produced without defects.

Try Prolean Now!

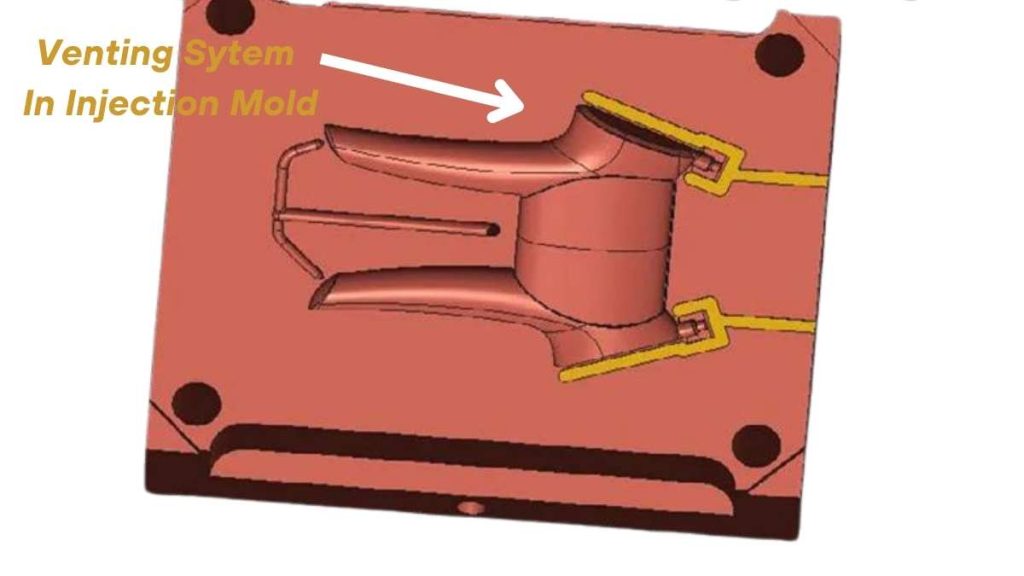

6. Mold Venting System

Mold venting system

The mold venting system is intended for the removal of the air and gases, trapped in the mold cavity. These systems comprise vents or grooves that are deliberately positioned to release air as the molten plastic material is injected into the mold to ensure that it fills the cavity correctly. Venting effectively helps to avoid the formation of air pockets and incomplete filling of the product, which is critical in the formation of various defects in the final product. Cleaning and maintenance of the venting channels have to be carried out frequently to ensure that they do not get blocked and thus produce quality moldings for the company.

7. Hot-Runner System

Mold hot runner system

The hot-runner systems are sophisticated mold components, that primarily, do not require conventional runners, surround individual cavities, and connect them to the sprue; instead, the material is supplied through the heated manifold and directly to the cavities by gating systems. These systems eliminate wastage of material and increase the quality of the part due to accurate temperature regulation. Moreover, improves the efficiency and flexibility of a production line. To run without failure, the system needs frequent checks to figure out problems to ensure it continues to perform efficiently. This will eventually, reduce production costs, and at the same time produce quality products.

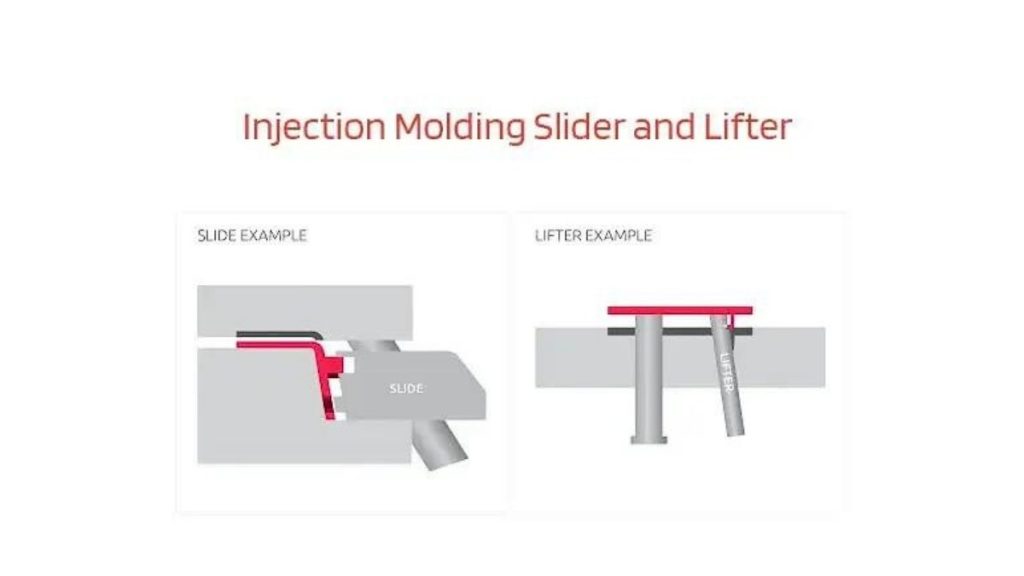

8. Injection Mold Slider

Injection mold slider

A slide is an insert mold part that allows undercuts or side holes, etc on the molded part to be made. These are located inside the mold and normally have freedom of movement in a plane perpendicular to the injection direction. Slides are activated by the injection molding machine and therefore must be well positioned to avoid binding. Made of strong materials such as hardened steel, they need proper engineering and constant maintenance to function properly. Effective slides are critical in creating complex components of high precision and within the shortest time possible.

9. Mold Interlocks

Mold interlocks

Mold interlocks play an important role in holding mold components especially the cavity and core halves in place. They help eliminate problems like flashing, warping, and other issues to do with dimensioning. Interlocks are of different types such as pin, groove as well as slot. Depending on the type of operation, they may be activated mechanically or with the help of hydraulic signals.

Common Materials for Injection Mold Components

The below table provides the common types of material used for different injection mold components, and their characteristics along with the material used frequently.

| Injection Mold Part | Materials |

| Mold Base | Tool Steels (P20, H13), Aluminum Alloys |

| Core/Cavity | Tool Steels (P20, H13), Pre-Hardened Steel (4140), Aluminum Alloys |

| Nozzle/Sprue | Tool Steels, Hard Steel Alloys (Nickel, Beryllium Copper) |

| Inserts | Metals, Ceramics, Reinforced Polymers, Carbon Fiber |

| Mold Interlocks/Guiding System | Tool Steels, Hard Steel Alloys |

Try Prolean Now!

Summary

Injection mold components are the most important in the injection molding method since they determine the quality of the final product. It is therefore important that the different components are well-managed and maintained to get the best results.

Prolean Tech is a fast manufacturing company that particularly in the provision of rapid tooling services. As a result, Prolean Tech has a team of molding professionals and state-of-the-art manufacturing facilities that enable the company to address various demands for injection molding services.

In addition, Prolean Tech offers exact specification products according to your design, material type, quantity, and cost restraints. Our emphasis on design optimization and strict quality control guarantees efficient work and high-quality products. Begin your project with Prolean Tech today by uploading your CAD files to help in the manufacturing process.

FAQ’s

Q1: How are injection molds made?

The injection molds are produced using 5-axis machining to cater to the complexity of the molds’ shape, and then polishing to give a smooth touch to the molds.

Q2: What is the material used in making injection molds?

Molds are generally made from steel or some form of aluminum alloy; however, plastics, resins, and rubbers can also be used where the load is not very high based on the manufacturing requirements.

Q3: What are the typical defects that are observed in the injection molded parts? How can such defects be prevented?

Some common defects are sink marks, warping, and short shots. These can be reduced by proper design of the mold, control of process parameters, and material flow and cooling system.

0 Comments