CAPABILITIES

Plastic Machining Service

Choose ProleanTech for Complex and precise plastic parts for your project! A reliable CNC plastic machining service for both prototyping and full-scale production at competitive rates.

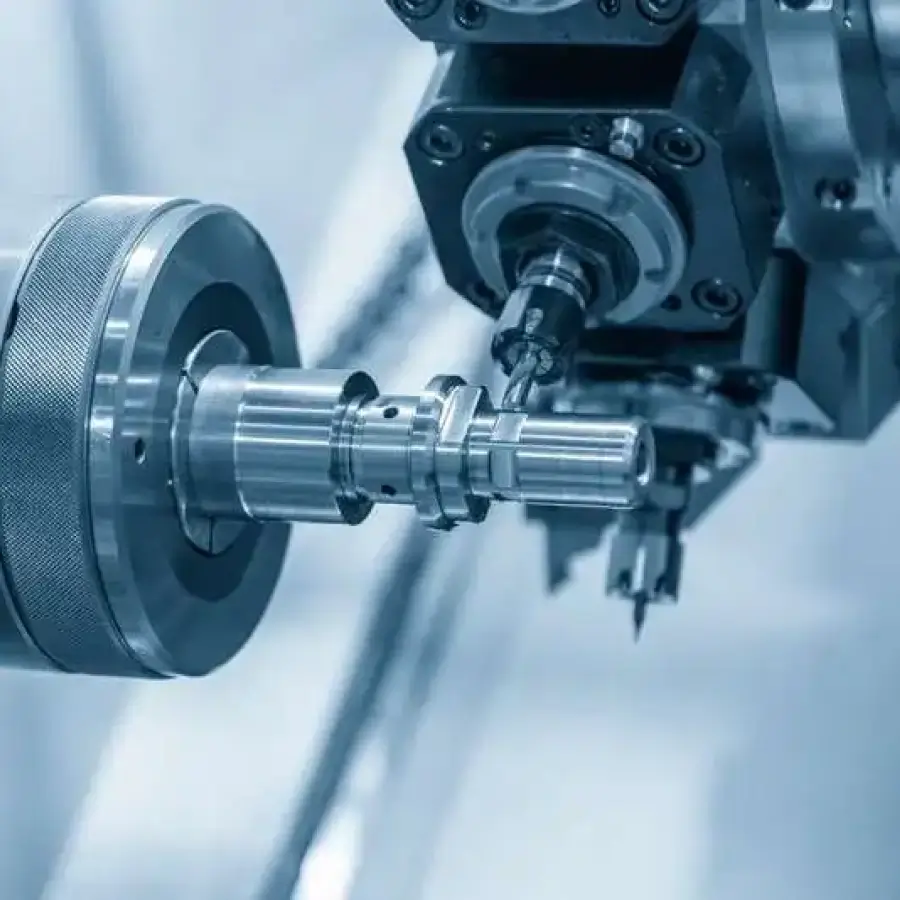

• Muti-axis CNC lathes and machining equipment

• Tolerances as low as ±0.0002″ (0.005mm)

• Lead time as short as 1 day

All uploads are secure and confidential.

Plastic Machining Capabilities

- Advantages of CNC Plastic Machining

Plastics are lightweight, corrosion-resistant, and often more cost-effective than metals. They offer good electrical insulation and can be colored easily. The softness of plastic reduces the machining cycle time and the tool wear. Meanwhile, machining stability allows for complex and intricate details via milling, turning, drilling, tapping, grooving, and other suitable operations.

- What we do to make Plastic Machining Perfect

Our machining factory has 3, 4, and 5-axis CNC lathes and a machining center that can process various thermoplastics and thermosets with a precision of ±0.005mm. We handle ABS, PC, PE, PMMA, and other plastics based on your requirements. Furthermore, we also have post-processing and finishing facilities to enhance the surface quality according to your application needs.

You can trust our experience in handling any machined plastic components!

Our Plastic Machining Properties

| Part size limitation | 72″ x 20″ x 6″ |

| Wall thickness | 0.0315” (0.8 mm) |

| Linear and radial tolerance | ± 0.01 mm and ±1° |

| Max. hole diameter | 5.5” |

| Flaness | 0.01” |

| Lead time | As fast as one day |

| Strengths | Machinability, Lightweight, dimensional stability, and low cost |

| Weaknesses | Susceptible to heat and melting, risk of warping |

Try Prolean Now!

CNC Plastic Material Grades

Plastic Machining Finishes

The custom CNC Plastic machining parts can be finished using different techniques to achieve specific surface properties and appearance. At ProleanTech, we have various surface finishing options, tailored to your needs.

As Machined:

The as-machined finish retains the machining marks, but it can be enough where the aesthetic is not required or finish quality does affect the functionality and performance. It is quick and cost-effective.

Bead Blast:

Glass or other less aggressive beads are suitable for plastic machining parts. It removes the imperfections and makes a uniform surface texture by removing a thin material layer.

Painting:

The good adhesive nature of plastic easily accepts the layer of paint to the surface of the plastic part, either for aesthetic reasons or to add protective coatings—glossy and protection against UV light, chemicals, and wear.

Brushing:

The abrasive brush rotates and removes the imperfection and burrs to create a uniform texture, providing a satin-like appearance.

CNC Plastic Applications

Automotive

Plastic machining in automotive is used for lightweight and corrosion-resistant complex and precise plastic components, which enhance fuel efficiency and durability. Examples; door handles, interior parts, bumpers, dashboard, fender liners, and lighting components.

Aerospace

The high strength-to-weight ratio and thermal stability of plastics ensure reliable, lightweight components for aerospace applications like electrical insulation parts, control knobs, and levers, aircraft windows, panels, bearings, seals, etc.

Defense

Plastic’s strength, durability, impact resistance, and lightweight can be converted into precise functional parts with exact specifications for defense equipment and navigation systems using CNC machining, such as armor parts, UAV parts, communication device housings, and radar systems.

Electronics

The electrical insulation, strength, and lightweight of plastics make them perfect for various detailed electronic components and enclosures, such as circuit board elements, connectors, sockets, insulation barriers, mounting brackets, LCD screens, etc.

Medical

Biocompatible and sterilizable plastics allow precise, custom medical devices and implants tailored to patient needs.

General Applications

Plastic machining offers durability, precision, versatility, cost-effectiveness, and precision, suitable for a wide range of industrial and consumer products; kitchen tools, industrial parts, toys, and low-friction strips for conveyors.

CNC Plastic Parts Gallery

Plastic Machining FAQs

What is Plastic Machining?

Can plastic parts be machined to tight tolerances?

What are the benefits of using plastic over metal in machining?

● Corrosion Resistance: Many plastics are highly resistant to chemicals and corrosion.

● Cost-Effective: Plastic materials are often cheaper and easier to process than metals.

● Electrical Insulation: Plastics typically have good electrical insulating properties.

How does plastic machining compare to plastic injection molding?

● Tooling Costs: Machining has lower initial tooling costs compared to injection molding.

● Flexibility: Machining offers more flexibility in design changes and prototyping.

How do I choose the right plastic material for my project?

● Mechanical properties (strength, flexibility)

● Thermal properties (heat resistance)

● Chemical resistance

● Electrical properties

● Cost

● Application requirements

Consulting with a knowledgeable plastic machining provider can help you make the best material choice for your project.

⁕ If you have any other question, feel free to reach out to us for help. Get in touch with our engineer to discover more about plastic machining!

Explore More Services

CNC Machining

Online CNC Machining Service for custom parts. Low-cost and rapid prototyping for your projects.

CNC Milling

Custom Online CNC milling service with 3-axis & 5-axis milling center creating complex geometries.

CNC Turning

Highly experienced CNC-turning prototype & batch production. Budget-friendly turning solutions.

CNC Turning Milling

CNC Turning Milling Service perfect for high-precision parts with complex geometries.

Injection Molding

Injection molding service covers mold making, injection molding, over-molding, and insert molding.

Get Your Parts Made Today

All uploads are secure and confidential.