CAPABILITIES

Aluminum Machining Service

Aluminum is a high-strength-to-weight material with excellent corrosion resistance, machinability, and durability.

Our Aluminum CNC service can machine Al 6061, 7075, 2024, and other alloys for numerous applications with precision as low as ±0.125mm.

All uploads are secure and confidential.

Aluminum Machining Capabilities

- Advantages of Using Aluminum in Machining Operations

Aluminum alloys can offer the same strength as steel at nearly half the weight. From this, you can imagine how light aluminum is. Other properties like durability, electrical and thermal conductivity, competitive pricing, and higher machining speeds bring several other benefits to aluminum CNC machining projects.

- What can we do to make aluminum cnc parts perfect?

At ProleanTech, we have multi-axis(3, 4, 5-axis) CNC milling and machining centers to craft complex parts with intricate features from aluminum workpieces. Our diverse machining capabilities, like milling, turning, drilling, and threading, can accommodate different designs, from automotive and aerospace to electronics components.

Our engineers closely work with clients throughout the project to meet all the end requirements. The quality control team utilizes real-time monitoring for in-process control, CMM, and other advanced machines for post-machining inspections. So, we guarantee the precision and quality of each part we deliver. At the same time, we are flexible whether you need prototypes or collaboration for large-scale production!

Our Aluminum Machining Service

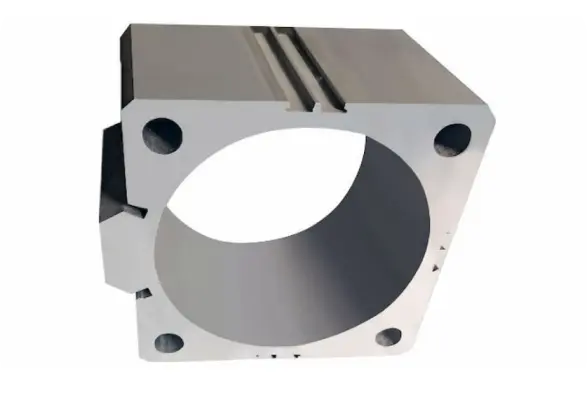

- Complex Aluminum Parts

The machinability and lightweight of aluminum allow for the creation of intricate aluminum parts like automotive cylinder heads, aircraft fuselage panels, etc. Additionally, we have a variety of tools are available to craft the countless geometries.

- Durability

Our custom CNC aluminum components have excellent corrosion resistance, wear resistance, and can withstand environmental conditions, thanks to a protective oxide layer that prevents rust and degradation.

- Precision & Affordability

The computer-controlled tool movement shapes the workpiece precisely and accurately. This method offers low costs due to aluminum prices and fast machining cycles. ProleanTech provides a rapid and custom tooling facility to further reduce costs.

- Quick Lead Time

Aluminum’s machinability allows for faster production cycles, resulting in lead times as short as 1 day. This efficiency is crucial for industries requiring quick production without compromising quality.

- Post-processing & Anodizing

The machining parts can be further processed with grinding, bead blasting, deburring, and polishing to increase the surface quality. These processed components can be further anodized with different colors for enhanced aesthetics, corrosion resistance, and surface hardness.

- Consistency

Our Aluminum CNC service produces consistent parts across the batches in terms of their features, dimension, tolerance, finish quality, and physical & mechanical properties. The main reason behind uniformity is minimal human intervention in the process.

Aluminum Machining Properties

| Part size limitation | 1,625.6 X 812.8 X 965.2 (64″ x 32″ x 38″) |

| Wall thickness | 0.8 mm |

| Linear and radial tolerance | ± 0.01 mm and ±1° |

| Anodizing thickness | 1.8- 25 μm |

| Lead time | As fast as 1 day |

| Strengths | High strength-to-weight ratio, corrosion resistance, high machining speed, and low cost. |

| Weakness | Softness and chip control |

Try Prolean Now!

Aluminum Machining Materials

ProleanTech offers various aluminum alloy grades for aluminum CNC services to address multiple manufacturing needs, including 6000, 7000 and 2000 series. Each of these grades has unique physical and mechanical properties.

Aluminum 6061 T651

Aluminum 6061 T651

The composition of 6061 alloy includes Aluminum 95.8 – 98.6, Mg 0.8 – 1.2 %, Copper 0.15 – 0.4, Silicone 0.4 – 0.8, Zinc 0.25, iron up to 0.7 %, and other minor alloying elements.

It is highly resistant to corrosion and can be machined and coated easily. However, it is relatively not as strong as other grades.

Aluminum 7075 T651 & T7

Aluminum 7075 T651 & T7

7075- T651 alloy contains Aluminum 87.1 – 91.4 %, Zinc 5.1 – 6.1 %, Magnesium 2.1 – 2.9 %, Copper 1.2 – 2 %, Chromium 0.18 – 0.28 %, and a minor amount of silicone and tin. These elements make it a high-strength alloy with excellent hardness, fatigue resistance, and thermal stability. It is commonly used in high-stressed applications. Meanwhile, 7075-T7 is similar to 7075-T651 but has been overaged to achieve a slightly lower strength in exchange for improved resistance to stress corrosion cracking.

Aluminum 2024 T3

Aluminum 2024 T3

Aluminum 2024 comprises 90.7 – 94.7 % aluminum, 3.8 – 4.9 % copper, 1.2-1.8% magnesium, 0.3 – 0.9% manganese, iron up to 0.5 %, and silicone, chromium, zinc, and tin in tiny proportion.

The major properties of this alloy are a high strength-to-weight ratio, good corrosion resistance, machinability, and smooth surface finish.

Material Comparison

| Grades | Temper | Tensile Strength(Mpa) | Yield Strength(Mpa) | Shear Strength(Mpa) | Rockwell Hardness(HBR) | Elongation at break (%) |

| Al 7075 | T651 | 538 | 462 | 330 | 150 | 3- 9% |

| Al 7075 | T7 | 462 | 386 | 300 | 135 | 8 % |

| Al 6061 | T651 | 310 | 276 | 207 | 95 | 17% |

| Al 2024 | T351 | 469 | 324 | 283 | 120 | 19 % |

Surface Finishing for Aluminum Parts

The custom CNC aluminum parts can be finished using different techniques to achieve specific surface properties and appearance. At ProleanTech, we have various surface finishing options, tailored to your needs.

As Machined: It includes visible tool marks and a slightly rough texture, with no additional finishing processes applied. The as-machined finish can be used where surface properties do not affect the performance.

Anodizing: The custom CNC aluminum parts can be coated for decorative purposes or obtain wear resistance and electrical insulation. Anodizing is one of the popular choices, which can achieve the Ra minimum of 16 µm and is available in various colors. ProleanTech has three types of anodizing options, type I, II, and III.

Beadblasting: A stream of glass or ceramic beads strikes the surface to remove imperfections and leaves a smooth, shiny finish. It is ideal for parts requiring further processing, like plating or coating.

Powder coating: Powder coating is widely used for its high-quality, long-lasting, and environmentally friendly properties on metals and other materials. It can be used in aluminum parts finishing for functional and decorative purposes.

Laser Engraving: It engraves the logo, serial numbers, pattern, text, image, and other features in aluminum machining parts. The uses are widespread, such as branding, personalization, and industrial marking.

Electroplating: Electroplating develops a thin layer of superior metal or alloy( chrome, nickel, etc) on aluminum machining parts through electrolysis. It enhances corrosion resistance, improves appearance, reduces friction, and can provide specific electrical or thermal properties.

Aluminum Machining Applications

The CNC machining aluminum parts can be found across industries fulfilling different manufacturing needs, including automotive, aerospace, medical, industrial equipment, and electronics.

Automotive

Engine blocks, cylinder heads, transmission housing, wheel rims, brake calipers, and other many aluminum automotive parts are made with CNC machining. It offers lightweight, strong, and durable components for vehicles.

Aerospace

Aluminum machining produces components for the aerospace industry with high precision and excellent strength-to-weight ratios, which is critical for the safety and performance of aircraft. Examples are fuselage panels, landing gear components, engine mounts, seat frames, and interior items.

Electrical and Electronics

Aluminum’s excellent thermal and electrical conductivity along with precise dimensions and high-quality finishes of CNC machining combined fulfill the requirement of components that must be precise, reliable, and capable of efficient heat dissipation. It can make components like heat sinks, enclosures, connectors, knobs, panels, etc.

Industrial Components

Custom CNC aluminum can withstand harsh operating conditions and lifespan is also longer. So, it is used in the manufacturing of complex and precise industrial equipment parts like fixtures, calipers, hydraulic cylinders, pump housing, gearbox components, robotic arms, etc.

Medical

The medical industry needs various precise and corrosion-resistant components for a variety of equipment and tools.

Aluminum CNC machining meets all the medical stringent requirements. It is used in the production of lightweight and biocompatible components, such as surgical instruments, biopsy needles, prosthetic components, diagnostic equipment housings, and medical furniture.

Energy

Aluminum parts are known for their accuracy, lightweight, high strength, and excellent corrosion resistance, which is crucial for the overall efficiency and reliability of energy systems. Aluminum CNC machining is used for turbine blades, heat exchangers, wind turbine components, generator housing, etc.

Aluminum Machining Parts Gallery

Get Your Parts Made Today

All uploads are secure and confidential.