“Polycarbonate injection molding is the process behind the large-scale production of polycarbonate products such as flashlight lenses, eye protection, and displays.”

Polycarbonate is among the widely used injection molding materials. Different industries use the process of polycarbonate injection molding as it helps them achieve the low-cost production of polycarbonate products. Companies that produce eye protection goggles, face shields, and helmets are one of the primary users of this technique.

The automotive industry also relies on this process as it provides efficiency to different lightweight automotive parts such as headlight lenses, interiors, and sunroofs. It is a versatile solution to all complex queries, allowing firms to make complex designs and shapes.

This article will discuss all the important aspects of polycarbonate injection molding, starting from the introduction to all the process parameters.

What is Polycarbonate Injection Molding?

Polycarbonate Injection Molding

Before starting with the basics of polycarbonate injection molding, let’s present a fact. Every material after the process of PC injection molding becomes strong and sturdy which makes it beneficial for most industries to consume.

Polycarbonates (transparent thermoplastic elements that have carbonate function groups) are high-strength materials that are highly resistant to impacts. In the process of polycarbonate injection molding, these sturdy materials are heated and melted to turn into any possible shape.

After undergoing this process, polycarbonates can be used to replace glass, which is why various sectors incorporate this process. It also helps manufacturers achieve low-cost production. The process of polycarbonate injection molding requires proper laboratories as it involves injecting molten polycarbonates into the mold. It needs proper caution and expertise to operate the machines.

Try Prolean Now!

Industrial Uses of Polycarbonate Injection Molding

There are many industrial uses of polycarbonates in the industries as it is sturdy and resistant to thermal conductivity. Here are some key real-life products as a result of polycarbonate injection molding.

Eyeglasses

Eye protection or goggles are primary examples of products of polycarbonate injection molding. These eyeglasses offer clarity and resistance to harmful ultraviolet radiation from the sun. To make goggles UV-resistant, manufacturers just add a UV stabilizer into the base material of injection molding.

Consumer Products

Daily Use Polycarbonate Products

Moving onto the daily use of consumer products, polycarbonates shine here as well because they offer excellent toughness. These materials are food-safe, which makes them easy to process in kitchenware manufacturing. As polycarbonates can withstand temperatures, they are ideal for kitchen equipment and comply with all food cleanliness and hygiene standards.

Medical Devices

In medical injection molding, polycarbonates offer high corrosion and thermal resistance making them an efficient material for most sterilized medical equipment manufacturing. When polycarbonates undergo irradiation, ethylene oxide, or steam autoclaving, they become highly ideal for medical devices as these processes often require high temperatures. Some key examples of medical equipment include syringes and incubators.

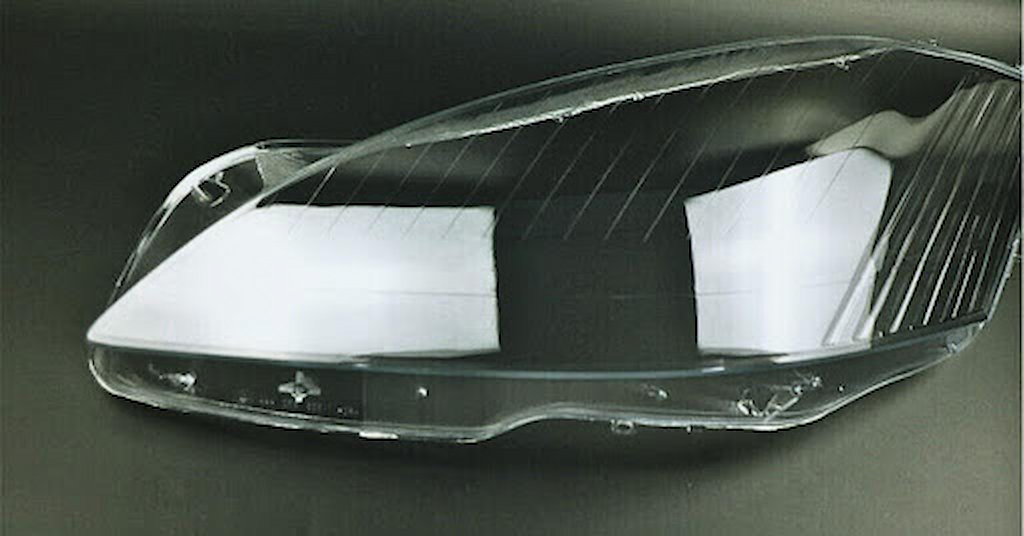

Automotive Products

Polycarbonates due to their superior optical clarity find tremendous use in the manufacturing of car headlights as they are mostly present in modern automotive parts. Car headlights, interiors such as power steering, and fuel systems are core examples of polycarbonate material.

Polycarbonate Car Headlight Part

The Pros of Polycarbonate Injection Molding

There are several use cases of polycarbonate injection molding as it offers versatile end products that can replace several real-life materials. This process has some upsides that make it attractive for most sectors globally. Here are the top 5 benefits of polycarbonate injection molding.

Quick Cycle Time

Every manufacturer needs a process that offers fast production at low costs. This is where the polycarbonate injection molding process shines as it takes comparatively less time than other industrial processes.

This makes this operation beneficial to companies as they can manufacture particular polycarbonate molds and get the desired shapes in fast cycles. Moreover, quick cycle times make the production of large-scale products as manufacturers can make several types of molds from this process.

This advantage becomes prominent, especially in the long run as companies can cut costs, reduce time wastage, and focus on better utilization of their raw materials.

Produces Parts with Precise Tolerances

Tolerance is the key aspect in every manufacturing process as it helps design engineers. When it comes to dealing with polycarbonates, tolerances play a pivotal role. Getting the right tolerance is necessary to achieve the right shape that directly impacts the effectiveness of the application.

In the process of polycarbonate injection molding, manufacturers can choose the desired tolerance by setting specific parameters. This enables them to achieve tight tolerances, making it easy to create the parts that are ideal for specific applications. In a nutshell, polycarbonate injection molding makes it significantly easier to accommodate a variety of product tolerances.

Accommodates a Range of Part Sizes

Another key benefit of polycarbonate injection molding is that it is a versatile process that makes it possible to create a wide range of part sizes. From the smallest of automotive panels to large headlight shades, polycarbonate injection molding helps manufacturers achieve their desired size of products. In the market, injection molding machines come with a set of settings that enable designers to set a specific type for the mold.

Easy Mass Production

Injection molding makes use of precision machined mold that produces parts at different levels of consistency. When it comes to tolerances, there is always a chance of variation in repeating the same product over and over again. To prevent these small deviations in geometries, the statistical process control is put into an injection molding machine. This allows easy mass production of various parts such as lenses by repeating the same process.

Effective Use of Raw Materials

Raw materials are most important In the industrial zone. They are costly and necessary to produce the right product. Thus, using these materials efficiently can help companies achieve maximum results. The injection molding process makes it possible. For instance, subtractive techniques such as machining can cause a lot of waste resulting in the loss of raw material, whereas polycarbonate injection molding fills the mold with only the precise amount of material required. The only waste of injection molding raw material in this process is small amounts of leftovers that stick to the mold runners. All other wastages in polycarbonate injection molding can be recycled.

The Cons of Polycarbonate Injection Molding

While polycarbonate injection molding offers many benefits, there are still some hurdles. Below are some of the challenges industrialists face.

Expensive for Low-Volume Parts

The process of polycarbonate injection molding requires a straight-up budget, which becomes difficult to manage if the production aims to produce low-volume parts. In the process of molding, the mold needs a proper design, after which it undergoes machining, heat treatment, and surface polishing. Carrying out all these processes for low-volume parts production can be costly and is not feasible in the long run. Therefore, manufacturers avoid the high cost and long lead time of injection molds as they are too expensive for low volumes. However, to deal with such issues, the manufacturer developed low-volume injection molding for the needs; in such cases, the molds are primarily designed for short life cycles so that the cost can be affordable.

Challenging Process

After walking through the advantages and use cases, let us discuss the process of polycarbonate injection molding, which is quite challenging. It becomes even more complicated at the time of injecting the mold. This is generally difficult as the mold is highly viscous, requiring a high temperature to inject thin-walled or fine-featured parts. In many instances, increasing the temperature can take it to the point where the material faces chemical degradation.

Difficult to Control Mold Moisture

One common problem of injection molding is controlling moisture as polycarbonates easily absorb it. Before injection, getting moisture into the mold can cause splaying and undesirable outcomes such as surface steaking.

Moisture also significantly impacts the mechanical properties of polycarbonates. Therefore, manufacturers must dry the moisture with a suitable desiccant before molding. One industry standard for optimal moisture in polycarbonates is less than 0.02%.

Related: Silicone Injection Molding

Try Prolean Now!

How Pro-Lean Can Help Enhance Your Manufacturing Capabilities with Injection Molding?

Prolean’s best-in-class polycarbonate injection molding process helps companies achieve the best possible results in large-scale productions. Get injection molding services for a wide range of parts production and plastic prototypes.

We offer extensive solutions to manufacturers with rapid tooling production that uses the latest thermoplastic injection molding techniques. Contact us today to get a complete walkthrough of your specific use case. Send your queries to get an instant quotation and design feedback from the team of industrial experts.

Summing Up

Polycarbonate injection molding has become a necessary operation in various industries as it enables manufacturers to replace many light parts with sturdy materials. For making products with different shapes, polycarbonates are recommended as they can produce multi-material parts with different geometric shapes.

It is always good to take precautions before starting polycarbonate injection molding as it can become difficult to execute for low-volume parts production.

Nonetheless, the process offers various advantages as discussed in this blog. With the advent of technology, the process will transform even further for more real-world applications worldwide.

FAQs

Q1. How to mold polycarbonates in injection molding?

Molding or thermoforming is the process in which polycarbonates are heated to convert into a soft flexible state, after which they can be put into a custom mold or tool to form the required geometrical shape.

Q2. What is resin in polycarbonate injection molding?

Polycarbonate resins are present in parts that require the highest toughness. These resins are present in a variety of transparent forms and are transformed into finished parts for injection molding.

Q3. What are the ideal conditions for molding polycarbonates?

Ideally, manufacturers have to keep an eye on moisture levels as it is the only factor that impacts the end product. Keeping it below 0.02% is recommended with temperatures between 70 to 120 degrees Celsius.

That’s what i need to get pverview of my next molding project! Great post

Thank you for your words!