3-Axis machining

When looking for parts requiring minimal multi-side details, you may wonder what CNC machine is the best. Using the 3-axis machining option is the most effective solution. It has enough capability to produce standard parts such as rectangles and squares.

While this machine is non-complex, it is also effective in producing slightly complex parts, providing the fixture is adequate. This type of machining is popular for its versatility, accuracy, and automation capability.

With a quality provider such as ProleanTech, the associated drawbacks such as cost and setup time should not worry you. We have already taken up the task and we have an experienced team that handles the machining flawlessly.

For all your parts in automotive, aerospace and many other industries using titanium, stainless steel, aluminum, and other metals, 3-axis machining is a one-stop solution.

In the following coverage of this machining approach, you will understand why the process is highly valued.

What is 3-Axis CNC Machining?

3-axis machining is done at the first level of multi-axis CNC (Computer Numerical Control) machining. That makes it the most basic type of multi-axis CNC machining. The term ‘axis’ in CNC machining can mean the directions of the cutting tool as it machines the workpiece.

For the 3-axis CNC machining setup, the cutting tool can move in three fundamental directions. These are the X, Y, and Z axes. The x-axis denotes the right-left movement, the y-axis is for the forward-backward movement, while the z-axis is for the up-down movement.

The three axes of machining

These three directions are mutually perpendicular to each other, and they allow for the movements that enable the CNC machine to produce the desired parts.

The unique thing about 3-axis machining is that the workpiece is stationary as the machining tool moves in the three directions. This is the secret to producing CNC machined parts of non-intricate shapes.

3-axis Machining Compared To 4-axis Machining

Adding an extra axis to 3-axis machining makes the setup a level more complex. The fourth axis makes the machining more versatile. This axis is not directional, but rather rotational, and called the A axis.

4 Axis CNC machining

The 4 axis CNC machining method adds a continuous machining capability that is difficult with the 3-axis CNC machine. In most cases, the rotational axis will be fixed to the X-axis. It is the reason 4-axis CNC machines can produce more complex parts than 3-axis machines can.

3-axis Machining Compared To 5-axis Machining

The 5 axis CNC machining type is a further expansion or improvement of the 3-axis CNC machine. It has the original X, Y, and Z axes, plus two rotational axes, which can be called A and C. This results in the capability of the workpiece and cutting tool to move in five different directions.

5-axis machining

The machining complexity of the 5-axis machine is much higher compared to the 3-axis machine. This machining can do a lot in a single setup – undercut, produce complex geometries, and so forth. It is perfect for industries that require intricate parts such as automotive, aerospace, and medical.

Try Prolean Now!

The Core Parts of a 3-axis CNC Machine

Like other types of CNC machines, the 3-axis machine comprises several parts including the column, cutting tool, and control panel. Here is a definition of some of the main parts of the machine.

Three Axes

The number of axes determines the capabilities and size of the CNC machine. For the 3-axis machine, the machine table can move in the X and Y directions. The third movement is usually attributed to the capability to move the cutting tool in the Z direction.

Control Panel

For flawless control of the 3-axis CNC machine, the control panel should be easy to access and use. It shows how the operator interacts with different CNC machine components and operations.

Control panel

A good example is inputting the G-code. The control panel has features that help with the CNC machining control through CNC programming.

Column

The standard 3-axis CNC machine contains one column, which not only carries the spindle but also allows the X, Y, and Z axes’ movements. However, some special 3-axis machines can contain a second column for specialized capability.

A double column machining center

Coolant System

Coolant system

The coolant system of the CNC machine comprises the coolant tank and the delivery system that takes the coolant to the machining area. Its function is to supply adequate coolant during the machining process. This special liquid is crucial for safeguarding the workpiece and cutting tool.

The Worktable

The worktable is the flat platform on which the workpiece is attached. A vice or fixture can be secured on this table to hold the workpiece. It comes with T-slots that make these attachments possible.

The Spindle

A CNC lathe spindle

The spindle is the engine of the 3-axis machine. Sitting on an axis, this component rotates during the machining process. It comprises a motor, a shaft, and a tools taper.

Try Prolean Now!

Popular Processes for 3-Axis CNC Machining

The CNC technology supporting different processes is often used with the 3-axis machining technology to control tools and produce parts. Some of the most common processes in this category are;

CNC Milling

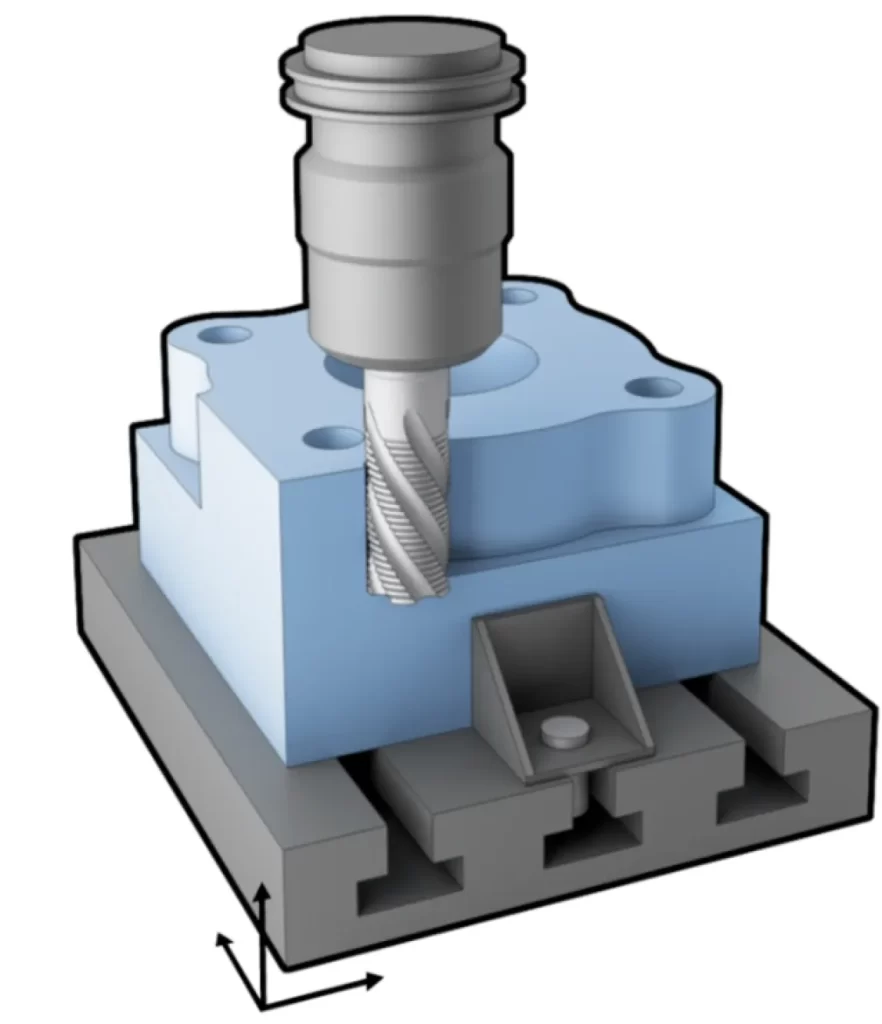

A 3-axis CNC milling machine contains a table that carries the workpiece to up to two planes of movement. A cutting tool is also capable of moving in up to three planes of movement. Depending on the configuration and workpiece requirements, the 3-axis CNC machine provides a collective three axis of movement.

3 Axis CNC milling

CNC Lathe

The CNC lathe is devised to rotate a workpiece on chucks as a fixed tool removes material. This type of 3-axis machine is perfect for creating pipes, axles, and other cylindrical products.

CNC Plasma Cutter

CNC plasma cutters are preferred for cutting through sheet metal with precision and speed. They are popular in many industrial applications where metals such as steel and aluminum require regular cutting to produce intricate designs.

CNC Engraving Machine

The CNC engraving machine is preferred for the manufacture of detailed patterns on materials. They are extremely accurate and work on almost every material.

CNC Router

A CNC router could be termed as a low-cost CNC mill. It is built to create complex shapes on soft materials using a rotary tool. Being computer controlled is a big improvement to the conventional router.

A 3 axis CNC router

Parts of the CNC router include the gantries, motors, spindle, fixturing table, and toolholder.

CNC Machining Center

In its most basic form, a CNC machining center has three axes. Its rotating spindle has a drilling or milling tool. The workpiece is usually attached at the X axis and does not rotate.

A major difference between a machining center and a regular milling machine is the incorporation of an automatic tool changer in the milling center.

What Industries Need Parts From 3-Axis CNC Machining?

It is undoubtable that 3 axis CNCmachining is dynamic enough to support different processes for many industries. The processes we have highlighted above are central to production of parts for instrumental industries. These include aerospace and defence, among others.

Let us highlight this relevance in some more detail:

Aerospace Industry and 3-Axis Machining

Housings, brackets, and related components in the aerospace industry must be precise and lightweight, manufacturing requirements that are met through 3 axis CNC machining.

This CNC machining technology is capable of handling the relevant materials such as aluminum and titanium. 3-axis machining provides good machining tolerances that meet the strict requirements of this industry.

3-Axis Machining For the Defense Industry

The durability and dependability of CNC machined parts matters a lot in this industry. 3 axis machining is relevant because it is capable of machining the accurate and tough materials required, for instance, titanium and steel.

If you are in this industry and you need precisely-machined enclosures, transmission shafts, advanced 3-axis CNC machining at ProleanTech can help.

Automotive Industry And 3 axis Machining

The automotive industry requires many CNC-machined parts including engine blocks and transmission shafts. 3-axis CNC machining is a priority solution for this production because of the precision and reliability provided.

Virtually every automotive part can be machined using this technique that even supports mass production.

Automotive parts made from aluminum, stainless steel, brass, and many other materials can all be machined in the 3-axis machine setup.

Conclusion

This coverage of the 3 axis CNC milling machine operations has shown the features, capabilities, and applications of this technology. Despite the availability of more complex machining setups, the 3-axis CNC machines are still very relevant in many industries.

If you need CNC machined parts, this machine could be the solution. The good thing is that you don’t even have to invest in it. ProleanTech has the machines and expertise to deliver the parts you need in as fast as one day. Top quality is guaranteed.

Get in touch with our 3 axis CNC machining experts today for more details.

0 Comments